Tier III Open-ended problem

advertisement

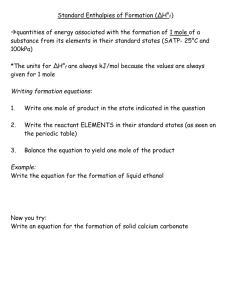

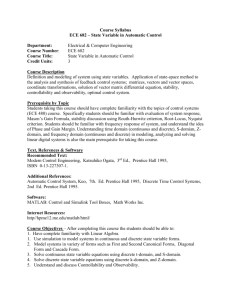

NAMP PIECE Tier III Open-ended problem Module 5 – Controllability Analysis 1 NAMP PIECE Tier III Statement of intent The goal of this tier is to solve few real-life applications of Controllability Analysis, in which the student must interpret the results obtained from a range of Controllability Analysis tools. At the end of Tier III, the student should be able to identify the following: Benefits of the use of Controllability Analysis tools Potential cost saving opportunities from the use of Controllability Analysis tools Environmental impact reduction resulting from the application of Controllability Analysis tools How the application of Controllability Analysis tools can be used to obtain an operable process Module 5 – Controllability Analysis 2 NAMP 3.1 PIECE Doukas and Luyben reported the transfer function model for the distillation column with a side stream product. The feed contains benzene (B), toluene (T) and xylene (X), with the benzene in the side stream of much less importance than the other controlled variables. The linearized transfer function model is: -1.986e-0.7s 5.984e -2.24s 5.24e -60s 14.3s+1 400s+1 66.7s+1 -0.42s -0.7s -0.6s 0.002e 2.38e -0.33e XDT (s ) 2 RR (s ) 2 2 1 XS (s ) 7.14s+1 1.43s+1 2.4s+1 B = -1.9s LSu(s) -0.5s -0.5s -11.7e 4.48e XD X (s ) -0.176 QB(s) 2 12.2s+1 11.1s+1 6.9s+1 ) s ( XB T -1.6s -3.8s -7.75s -9.81e -11.3e 0.374e 2 22.2s+1 11.4s+1 21.7s+1 The process is shown on the next slide. Module 5 – Controllability Analysis 3 NAMP PIECE Distillation column with a side stream product. RR (Ratio) Feed flow rate XDT (mole fraction) XSB (mole fraction) LS (lb mol/ hr) XSX (mole fraction) QB (BTU/ hr) XBT Determine the best loop pairing and calculate the Niederlinski Index for each subsystem considered. Module 5 – Controllability Analysis 4 NAMP 3.2 PIECE The transfer function model for a pilot scale binary distillation column used to separate ethanol and water was given in TIER 2, The process variables are (in terms of deviations from their respective steady state values): y1 = overhead mole fraction ethanol u1 = overhead reflux flowrate y 2 = side stream ethanol mole fraction u2 = side stream draw-off rate y3 = Temperature on Tray #19 u3 = reboiler steam pressure 0.66e-2.6s 6.7s+1 y 1 -6.5s y = 1.11e 2 3.5s+1 y 3 -33.68e-9.2s 8.15s+1 -0.61e-3.5s 8.64s+1 -2.3e-3s 5s+1 46.2e-9.4s 10.9s+1 Module 5 – Controllability Analysis -0.0049e-s 9.06s+1 u 1 -0.012e-1.2s u2 7.09s+1 u 0.87 11.61s+1 e-s 3 3.89s+118.8s+ 5 NAMP PIECE Distillation column used in separating ethanol and water Overhead mole fraction ethanol (y1) Temperature on tray #19 (y3) Feed flow rate (d) Overhead reflux flow rate (u1) Mole fraction of ethanol in the side stream (y2) Reboiler steam pressure (u2) Design a steady state decoupler using the generalized approach, with GR(0) chosen as Diag[G(0)]. Module 5 – Controllability Analysis 6 NAMP 3.3 TH1 PIECE S.G.Oliveira and F.S.Liporace [3] have obtained the Gain Array for the HEN showed below, where the manipulated variables are f1, f4, f5 , f7 and f8 should be used to control the outlets temperature TC1,TH1,TH2. C1A C1 HE 1 Q1 A1 TD1 f1 300 K C1B TH2 T1 395 K 365 K f4 C2 m1 HE 2 Q2 A2 TD2 T6 m5 C1A1 400 K T5 C1B1 398 K Module 5 – Controllability Analysis T2 H1 HE 3 Q3 A3 TD3 f5 T3 575 K m4 TC1 C3 358 K m8 T4 f7 HE 4 Q4 A4 TD4 T7 m7 f8 718 K H2 7 NAMP PIECE The gain array obtained for the system is: 17.483 4.733 6.267 11.652 8.088 K= 45.778 5.133 6.867 0 0 25.39 0 0 90.851 63.143 f1 f4 f5 f7 TC1 TH1 TH2 f8 Choose the best pairing, using the RGA and SVD. Module 5 – Controllability Analysis 8 NAMP PIECE References [1] Wood, R,K. and M.W. Berry, “Terminal Composition Control of a binary distillation column,” Chem. Eng. Sci., 29, 1808 (1973). [2] Ogunnaike, B. A., J.P. Lemaire, M. Morari, and W.H. Ray, “Advanced multivariable control of a pilot plant distillation column”, AICHE, 29, 632 (1983). [3] Oliveira, S.G., Lopirace, F.S., Araujo, O.Q.F. et al. The importance of control considerations for heat exchanger network synthesis: a case study. Braz. J. Chem. Eng., June 2001, vol.18, no.2, p.195-210. ISSN 0104-6632. [4] Ogunnaike, B. A. and Ray, W. H., Process Dynamics, Modeling and Control, Oxford University Press, New York (1994). [5] Marlin, T. M., Process Control Designing Processes and Control Systems for Dynamic performance, McGraw-Hill, United States of America (1995). Module 5 – Controllability Analysis 9