Gas Treatment Plant

advertisement

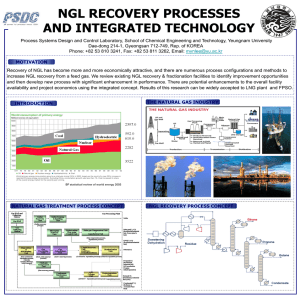

Gas Treatment Plant Chris, Stephanie, Kyle, Mariam Mentor: Jerry Palmer Outline 1. Block Flow diagram 2. Mass Balance 2. Liquid Knockout 3. Sour Gas Treatments 4. Gas Dehydration 5. NGL Recovery and CO2 Removal 6. NGL Stabilization 7. Inert Removal-N2 8. Equipment Cost 9. Capital Cost 10. Revenues 11. Sample Calculations 12. Question & Answer Block Flow Diagram Mass Balance Liquid Knockout 3- Horizontal Tanks and decreasing temperature and pressure. In a dynamic refinery environment it is important to have the capability to compensate for a surge of liquids and take out any non-volatile components which will cause issues in the future separation processes. 3 tanks are used because its the most efficient setup for large scale processes. 5 6 Sour Gas Treatment 7 Sour Gas Treatments Liquid Scavenger Solid Scavenger Liquid Redox Amine+Claus+Tail gas Acid Gas Yes Yes Yes Yes Natural Gas Yes Yes Yes No Turndown Sensitive Not Sensitive Not Sensitive Sensitive Products Streams Biodegradable Liquid Non-Hazardous Solid Sulfur Cake for Fertilizer Pure Sulfur Operating Costs $10/lb. of S $3.50/lb. Sulfur $0.15/lb. of S Small Equipment Costs Low Moderate Moderate High General Application Guidlines 100 lb. of sulfur per day 300 lb. of sulfur per day Less than 20 tons of sulfur per day Greater than 15 tons of sulfur perday and greater than 15% H2S 8 Gases treated Why LO-CAT II? -System Stability -Ease of operation and Catalyst consumption -Chemical Cost is roughly 1/2 to 1/3 of a Sulferox Unit -Uses a Patented chelate system that is more resistant to Oxidation Gas Dehydration Gas Dehydration & CO2 Rejection The methods of dehydration looked into are lean gas absorption, adsorption and membrane separation. Absorption Adsorption TEG dehydration Mole sieve dehydration Glycol is cost effective Adsorbent like silica gel is expensive For removing large quantities of water Required for cryogenic systems which need low moisture content Glycol can be replaced continuously Multiple adsorption beds are required for continuous use. Does not remove CO2 Removes CO2 12 PFD-003 Gas dehydration 13 NGL Recovery + CO2 Removal 14 NGL Recovery Mechanical Refrigeration Plant: - limited to -24 to -40 F - only 60% propane Lean oil absorption: - 40% ethane - 90% propane - 100% heavier hydrocarbons - Heating and cooling required - High operating cost Turboexpander: - 60-90% ethane - 90-98% propane -100% of heavier hydrocarbons - Since high percent ethane recovery is needed, this is the most economical way 15 16 NGL Stabilization 17 NGL Stabilization • • • NGL's need to be stabilized to a point that it can be stored and transported in nonpressurized vessels. Enhances the safety in handling, and improving the liquid's marketability. Stabilizing the liquid reduces the volatility. 18 19 Inert Removal-N2 20 Inert Removal-N2 Available options are cryogenic distillation, membrane separation and PSA. Cryogenic distillation has been selected on the basis that is very efficient for large scale separation facilities. Additionally because LNG is being produced in the following stage its worthwhile to expend the energy to process the methane. 21 22 LNG Production 23 LNG Production • • • LNG is produced under very low temperatures. Effective for transportation of natural gas over long distances. Safer than transporting compressed natural gas in vehicles because LNG is comparably low in pressure. 24 25 Equipment Cost Estimates Equipment Cost pump $20,000 to $85,000 distillation column $600,000 compressor $20,000 to $1,500,000 cryo distillation column $700,000 heat exchanger $50,000 to $100,000 primary LNG cryo heat exchanger $3,000,000 26 Estimated Capital Cost Amine Treating cost for 5% acid gas removal Dehydration cost Compression cost (7000hp x $1400/hp) Cryogenic NGL recovery cost Liquid-Redox Sulfur Recovery at 5 T/d Total cost of components Other costs and Contingency @ 30% Total Estimate Plant Cost $10.0MM $1.0MM $9.8MM $23.0MM $4.0MM $47.88MM $14.3MM $62.1MM -Based on a Natural Gas Treatment Facility that processes 100 MMscfd. -Prices based in 2008 and do not account for inflation. Employee payroll with fringe benefits $3.5MM/year Revenues • • • • • Natural Gas: 300 Million $/year NGL: 110 Million $/year LNG: 50 Million $/year Elemental Sulfur: 50,000 $/year 27 Sample Calculations SCFD to Lb/Hr conversion: X Lb/hr = ( Y SCFD) / [ ( 24 hr/1d)*(1 lbmol/ Z Lb)*(378.827 SCF /lbmol) ] V/n = RT/P = 378.827 @ 60F X : lb/hr Y : SCFD Z: MW X bbl = ( Y lbmol * MW lb/lbmol) / (5.615 ft^3/bbl*Z lb/ft^3) X= volume Y= n moles Z = density 28 Q&A