2006 Banner PowerPoint Format

advertisement

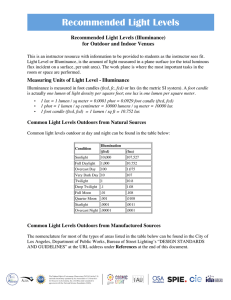

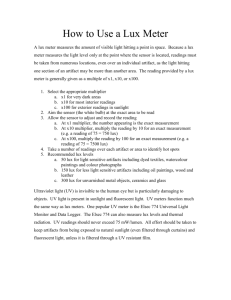

The Visual Factory Light It Up for Quality! Why Visual Management? How Do I Turn the Pump On??? Visual Management = Clarity Make it clear ■ What to do ■ That it was done correctly ■ If something went wrong ■ What needs to be improved The Visual Factory Goes Even Further Visual management (5S, etc.) Illumination + Indication Visual Factory Five Steps to the Visual Factory 1. Illuminate the work area 2. Use light-guided assembly when possible 3. Communicate process status to operators 4. Communicate status to supervisors 5. Communicate plant-wide status Light Up the Gemba ■ Gemba means “the real ■ ■ ■ ■ place” Proper illumination drives up quality by revealing defects Start by choosing an illumination level (lux) Lux = lumens/m² Example: 1000 lumen light over a 2 m² work surface = 500 lux Light Up the Gemba ■ Lux level required: ■ The Illumination Engineering Society recommended levels: Condition Clear Daylight Overcast Daylight Lux Application Recommended Lux 10,000+ Warehouse 100 1,000 Work Area 150 Hallway 100 General Assembly 1000 Twilight 10 Detailed Assembly 2000 Full Moon 0.1 Fine Inspection 5000 Clear Daylight Overcast Daylight Hallway Twilight Light Up the Gemba ■ What is color temperature? – The temperature of a black body radiating a comparable hue to the LED color – Higher temperatures (eg., 5000°K) are bluer (cool white) – Lower temperatures (eg., 2500°K) are yellower (warm white) ■ Why is it important? – Cool whites produce more contrast in general – For color-based inspections, the color temperature will be specified such as D50, meaning Daylight 5000°K What About Light Consistency? ■ The Illumination Engineering Society recommends no more than a 3:1 ratio of light intensity ■ You can get a quick read of this with a Lux meter app on your iPhone ■ See Megaman Lux Meter Why Use LED Lighting for Work Areas? ■ Flicker-free light ■ Highest efficiency (3 x lumens/W) ■ Long life (50,000 hrs) ■ Non-hazardous materials ■ Compact size ■ Higher color temp Use Light Guided Assembly Use Light Guided Assembly Use Light Guided Assembly Use Light-Guided Assembly Banner Offers Four Levels of Guide Lights Simple Indicators Indicators with Buttons Indicators with Sensors Indicators with Sensor Arrays Communicate Status within the Work Cell ■ The problem with traditional indicators is that they require a panel or enclosure and end up mounted away from the operator’s direct view ■ Banner indicators are designed for direct machine mounting ■ They can also be moved and adjusted for continual improvement Communicate Status within the Work Cell Human Factors Engineering ■ According to principles of Human Factors Engineering, visual indicators should be: – Conspicuous - mount them where they make sense, not simply where the electrical enclosure happens to be mounted – Unambiguous - indicators should be free of color when in the off state Depending on the ambient lighting, it’s not immediately clear which lights are on and off ■ Only EZ-LIGHTs can provide this. – The color goes to gray when the light is off ■ Reduces “visual clutter” Communicate Process Status at the Cell Level ■ Banner tower lights and beacons are pre-assembled, so they can be deployed quickly ■ Because they are LED-based, there is no need to take them apart and replace bulbs Use Wireless to Communicate Status Plant Wide ■ The sender and receiver of information are often separated by long distances ■ Wireless solutions are the fastest and most costeffective way to make the link ■ Continuous improvement: “Decide carefully; implement quickly.” The Visual Factory Links People to the Process ■ The Visual Factory is the foundation of all quality systems ■ It enables Kaizen, continuous improvement, by assemblers, supervisors and managers ■ Banner has the widest array of Visual Factory solutions available Thank You Questions?