running of 25t axle load trains

advertisement

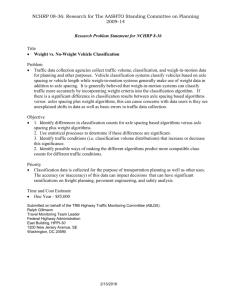

INTRODUCTION OF HIGHER AXLE LOADS ON INDIAN RAILWAYS Shiv Kumar Director/IRICEN Introduction of higher axle loads on IR After experience of successful run of the pilot project of running of CC+8+2 trains and introduction of axle load of 22.82 t on IR since May,2005 on identified iron ore routes, Hon. MR announced in his Budget Speech ,06 that 25 T axle load trains will be introduced on IR during the year 06-07. Initially ,two routes have been identified as under: 1.Dallirajahara-Bhilai 2.Banspani-Daitari Indian Railways march towards heavier axle loads Universalise 22.82 t axle load on IR Construct Dedicated Freight Corridors (DFC) fit for 30 t axle loads Feeder Routes To DFC to be strengthened for running of 25 t axle load operations Other routes identified for upgradation for 25 t axle load operation Proposed Axle Load &TLD for DFC Formation & Bridges : 30 t Track for DFC : initially 25t which can be upgraded to 30t subsequently Trailing Load Density (TLD):12 t/m Track Structure for DFC For 30 t axle load 68 kg (90 UTS or higher) Rails New Design of PSC sleeper, 1660/km E-clip elastic fastening with improved rubber pads being developed by RDSO Flash butt welded joints Thick Web Switches and swing nose crossings in turnouts PSC sleepers to be designed for turnouts ,level crossings , SEJs, Bridge Approaches Formation,gradients ,curvature for DFC Formation width in embankment/cutting and centre to centre spacing: -Single Line 6.85 m (as existing) -Double Line 12.35 m - C/C spacing of DFC tracks 5.50 m -C/C spacing of DFC from existing 6 m Suitable thickness of sub-ballast/blanket/reinforced earth to be provided Curvature limited to 700m (2.5 degree) Ruling Gradient - 1 in 200 compensated Proposed Loading Standards for bridges on DFC Loading Standards –Heavy Mineral loading Locomotives: Axle Load - 30 t Tractive Effort - 60 t per loco for double headed - 45 t per loco for triple headed Braking Force - 25 t per loco Train Loads: Axle Loads - 30 t Trailing Load Density-12t/m MMD for Dedicated freight Corridor TRACK STRUCTURE FOR RUNNING 25T AXLE LOAD TRAINS As per Railway Board’s Track Policy Circular no.2 of 2006 dtd 19th July,06,the minimum track structure for routes identified for running of 25t axle load trains, to be adopted in all future track renewals, construction of new lines, doubling etc. will be as follows: Rail Section……..……60kg 90UTS Sleepers and density….PSC of existing design , 1660 nos per km Ballast cushion……….300mm Points & crossing……Fan-shaped layout with 60kg curved switches TRACK STRUCTURE FOR RUNNING 25T AXLE LOAD TRAINS (contd.) Existing track structure consisting of 52kg 90UTS rails on PSC sleepers with 1540 nos. per km and 250mm ballast cushion may be permitted for running of 25t axle load trains at a restricted speed of 60 kmph, for BOXN and similar type of wagons. In case of sidings, the minimum track structure for 25T axle load operation will be of 52kg 90UTS rails on PSC sleeper with 1540 nos. per km and 250mm ballast cushion for speeds upto 60 kmph. In cases where speed is not exceeding 30kmph, track structure comprising of 52kg 72UTS rails on PSC sleeper with 1540 nos. per km and 250mm ballast cushion will suffice. TRACK RENEWAL FOR 25T AXLE LOAD OPERATION (contd.) 52kg 90UTS rails will be replaced only when they become due for renewal on age-cum-condition basis. Wherever the existing sleeper density is 1540 nos per km, works for increase in sleeper density alone will not be sanctioned. These will only be done as and when sleeper replacement is required, either due to age-cum-condition basis or to suit higher rail section. TRACK RENEWAL FOR 25T AXLE LOAD OPERATION (contd.) Where track renewal is sanctioned as 52kg 90UTS rails and PSC sleepers with 1540 nos per km., the sleeper density should be increased to 1660 nos per km by Material Modification. Railways should, however, start execution with the increased sleeper density pending approval of MM estimate, to avoid the delay. It however should also be ensured that MM gets sanctioned within three months. Rail section should immediately be modified to 60kg 90UTS rails, wherever it is feasible. For other cases, it should start within next 6 months. During this period, preparatory work such as procurement of related fittings etc. be ensured. Railway should also ensure sanction of MM estimate within three months. EXAMINATION OF EXISTING BRIDGES FOR 25T AXLE LOAD (Feeder routes): Bridges have to be checked for 25 t axle load & trailing load density of 9.33t/m. Works already planned and awarded especially for construction of bridges/rebuilding will be as per existing loading standards( i.e. MBG) Correction slip no 23 & 34 issued by RDSO no CBS/PSBC dtd.21/23.03.06 ,CBS/PBR dtd.24/26.05.06 respectively should be taken into account while checking the suitability of existing bridges Superstructure: RDSO has examined on following premises: Actual axle load and axle spacing for moving loads of WAG9 locomotive and 25 T BOXN wagons. Coefficient of Dynamic Augment (CDA) for limited speed of 60kmph . RESULTS OF ANALYSIS superstructures of standard spans): (for SPEED POTENTIAL OF BRIDGES FOR DIFFERENT LOADING STANDARDS OF EXISTING BRIDGES STANDARD SPAN(M) BGML LOADING Axle load 22.9T TLD 7.67T/M T. Effort 47.6T RBG LOADING Axle load 22.5T TLD 7.67T/M T. Effort 75.0T MBG LOADING Axle load 25.0T TLD 8.25T/M T. Effort 100.0T 1-20 60kmph 60kmph 60kmph 20-63 60 kmph 55 kmph 60 kmph 78.8 50 kmph 55 kmph 55 kmph • Substructure: Substructure analysis to be done case by case. • Bearings: – Bearings of standard spans designed for MBG loading are fit for 25 T axle load. – Bearings of standard spans designed for BGML/RBG loading having spans 31.9m, 47.25m, 63.0m and 78.8m (all effective spans) needs strengthening. – One time inspection of Bearings apart from schedule inspection to be done by Zonal Railways for running of 25 T axle load. 15 Bridge Inspection and Monitoring Following locations/members to be monitored as being critical from fatigue consideration. Connection of cross girder with stringer. Outstanding leg of the top compression flange of the stringer at its junction with web rivet. Rivets connecting bottom flange angle of the stringer with web at mid span. Vertical members at connection with top chords. Rivets connecting bottom flange of cross girders with web at mid span. Rivets of splice joints of bottom flange in plate girders. Physical condition of bridges to be certified by Zonal Railways. More intensive Bearing & Substructures Inspection to be done ( will need more man power) Directions for checking superstructure of non standard spans including Arch Bridges etc., bearing of non standard spans and substructure of all bridges issued to Zonal Railways. Conclusions Experience of increased axle load on other major railway systems in world has shown that Fatigue life of rail comes down drastically with increase in axle loads and it may take 5 to 10 years for heavy axle loads to tell its effect on rails. Rail grinding is required to be undertaken to prevent Rolling Contact Fatigue and increase rail life. The rail life obtainable under present axle load itself is in range of 350-400 GMT which is way below the prescribed life of 800 GMT for 90 UTS rails. Till rail grinding is implemented, there is a need to safe guard against rail fractures due to RCF by extensive and effective USFD. Fatigue life of rails also needs a review. Life of rails subjected to heavier axle load needs to be realistically brought down till grinding is introduced. Conclusions Installation of way-side vehicle condition monitoring systems for identifying poorly performing wagons will go a long way in reducing stress state of track by identifying defective rolling stock and removing them from service. These are: Wheel Impact Load Detector (WILD), Truck Performance Detector (TPD), Hot Bearing Detector (HBD), Dragging Equipment Detector (DED), Hot Wheel Detector (HWD), Truck Hunting Detector (THD), Wheel Profile Monitoring System etc Development of track friendly bogie, self steering is required. Review after one more year of operation of 22.82t axle load may help to firm up the position.