Facility Location Models

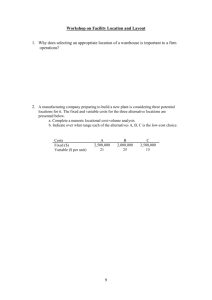

IES 371

Engineering Management

Chapter 10: Location

Week 11

August 17, 2005

Objectives

Identify the factors affecting location choices

Explain how to apply the various methods to location decisions

1

Dr. Karndee Prichanont IES371 1/2005

Facility Location

Competitive Advantages

The need to produce close to the customer due to time-based competition, trade agreements, and shipping costs.

The need to locate near the appropriate labor pool to take advantage of low wage costs and/or high technical skills.

2

Dr. Karndee Prichanont IES371 1/2005

Issues in facility location

Proximity to Customers

Business Climate

Total Costs

Infrastructure

Quality of Labor

Suppliers

Other Facilities

Free Trade Zones

Political Risk

Government Barriers

Trading Zones

Environmental Regulation

Host Community

3

Dr. Karndee Prichanont IES371 1/2005

Plant Location Methodology:

Location Factor Rating

Procedures

1

1.

Identify factors that are important in the location decision

2 3

Scores ( 0 to 100 )

Location Factors Weight Site 1 Site 2 Site 3

Labor pool & climate

0 .

30 80 65 95

Proximity to supplies

0 .

20 100 91 75

2.

Prioritize the factor by its importance. Each factor is weighted from 0 to 1.00

Wage rates

0 .

15 60

Community environment

0 .

15 75

95

80

80

80

4

3.

Subjective score (0 to 100) is assigned to each site for each factor

Location Factors

Labor pool & climate

Scores ( 0 to 100 )

Site 1 Site 2 Site 3

24 .

00 19 .

50 28 .

50

Proximity to supplies

20 .

00 18 .

20 15 .

00

4.

Sum up the weighted score.

Wage rates

9 .

00 14 .

25 12 .

00

Community environment

11 .

25 12 .

00 12 .

00

5.

The site with highest score is the most attractive

See also Example S5.1

64 .

25 63 .

95 67 .

50

5

4

Dr. Karndee Prichanont IES371 1/2005

Plant Location Methodology:

Center-of-Gravity Technique

Used for locating single facility that considers existing facilities, the distances between them, and the volumes of goods to be shipped between them.

Involves formulas used to compute the coordinates of the twodimensional point that meets the distance and volume criteria stated above.

x

The coordinates for the location of the new facility are computed as follows: i n

1 x i

W i i n

1

W i

, y

i n

1 y i

W i i n

1

W i x, y = Coordinates of the new facility at center of gravity x i

, y i

W i

= coordinate of existing facility

= Annual weight shipped from

I facility i

See also Example S5.2

5

Dr. Karndee Prichanont IES371 1/2005

Ex 1 : Center-of-Gravity Technique

Several automobile showrooms are located according to the following grid which represents coordinate locations for each showroom.

Y

D

(250,580)

Q

(790,900)

Showroom

A

D

Q

# of Z-mobiles sold per month

1250

1900

2300

A

(100,200)

(0,0)

X

Question:

What is the best location for a new Z-Mobile warehouse/temporary storage facility considering only distances and quantities sold per month?

6

Dr. Karndee Prichanont IES371 1/2005

Plant Location Methodology:

Load-Distance Technique

Various locations are evaluated using a load-distance value.

For a single potential location, a load-distance value (ld) is computed as follows:

Select the location with lowest ld value

LD d i

i n

1 l i d i

x i

x

y i

y

2 x, y = coordinates of the new facility x i

, y i

= coordinate of existing facility

LD = the load-distance value l i d i

= the load expressed as weight, number of trips, or unit

= the distance between the new and existing facility

Ex 2 : From ex 1, evaluate two possible different sites of warehouse to supply to showroom A, D, and Q. Given that

Warehouse site 1: x = 420 and y =450

Warehouse site 2: x = 250 and y =980

7

Dr. Karndee Prichanont IES371 1/2005

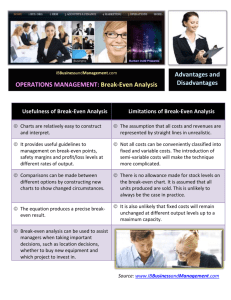

Plant Location Methodology:

Break-even analysis

1.

2.

3.

4.

Also refer to Supplement A –

Decision Making

Basic steps for break-even analysis in facility location decisions:

Determine variable costs and fixed costs

Plot the total cost lines (sum of fixed costs and variable costs) for all alternatives in a single graph

Identify the approximate ranges for sites with lowest total cost

Solve algebraically for the breakeven points over the relevant ranges

1600

1400

1200

1000

800

600

400

200

0

Break-even point

A best B best C best

2 4 6 8 10 12 14 16 18 20 22

6.25

14.3

Q (thousands of units)

8

A

(20, 1390)

(20, 1200)

(20, 1060)

(20, 980)

Break-even point

D

B

C

Dr. Karndee Prichanont IES371 1/2005

Ex 3

: Break-even analysis

Ethel & Earl Griese narrowed their choice for a new oil refinery to 3 locations.

Fixed and variable costs are as follows.

Locations

Albany

Baltimore

Chattanooga

Describe the appropriate decision plan for this company.

Fixed cost per year

$350,000

$1,500,500

$1,100,000

Variable cost per unit

$980

$240

$500

9

Dr. Karndee Prichanont IES371 1/2005

Plant Location Methodology:

Transportation Method

A quantitative approach based on linear programming

To determine the allocation pattern that minimizes the cost of shipping products from 2 or more plants ( source of supply ) to 2 or more warehouses ( destinations )

This method is find the best shipping pattern between plants and warehouses for a particular set of plant locations with given capacities

10

Transportation Tableau

Dr. Karndee Prichanont IES371 1/2005

Plants

1

W arehouses

2 3 4

Capacity

Requirements

11

Dr. Karndee Prichanont IES371 1/2005

Ex 3

: Transportation Method

Fire Brand makes sauce in EL Paso and New York City. Distribution centers are located in Atlanta,

Omaha, and Seattle. The shipment costs per case are as shown in the table.

FROM /

TO Atlanta Omaha Seattle

El Paso

NYC

$ 4

$ 3

$

$

5

7

$

$

6

9

The demand for Atlanta, Omaha, and

Seattle are 8,000, 10,000, and

4,000 cases per month respectively. The plant in El Paso has production capacity of

12,000 cases / month, while the plant in New York City has production capacity of 10,000 per month.

Determine the shipping pattern that will minimize transportation costs.

What are the estimated transportation costs associated with this optimal allocation pattern?

12