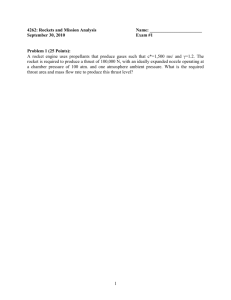

Principles of Propulsion and ist Application in Space

advertisement

Principles of Propulsion and its Application in Space Launchers Prof. Dr.-Ing. Uwe Apel Hochschule Bremen 13.07.2012 REVA Seminar 1 Overview • • • • • • • • • How Rockets are Propelled Thrust Generation in a Rocket Engine Rocket Engine Performance Parameters Classification of Space Vehicles Application of Rocket Engines Classification of Rocket Propulsion Systems Physical Limits of Chemical Space Propulsion The Rocket Equation Staging of a Rocket 13.07.2012 REVA Seminar 2 How Rockets are Propelled • The Change of the state of motion of a rocket follows the principle of repulsion • Newton‘s law applies: ACTIO = REACTIO Any force acting on a mass creates an force of the same size in the opposite direction! • By ejection of a mass at a high velocity (usually a hot gas flow ) from the rocket engine a force is produced changing the momentum of the rocket. Important: According to Newton‘ law of momentum conservation d d ( m1 × v1 ) + ( m2 × v2 ) = 0 dt dt the sum of the momentum changes of working fluid and vehicle equals 0 ! 13.07.2012 REVA Seminar 3 Functional Principle of a Rocket Thrust is generated pi pi m 13.07.2012 F = m× we REVA Seminar exits nozzle with velocity we 4 Thrust Generation in a Rocket Engine m × we = òp ( x,r ) dx - Ae × pe + Ae × pa = F - Ae × pe + Ae × pa CS 13.07.2012 REVA Seminar 5 Rocket Engine Performance Parameters Thrust : Characteristic velocity : F = m × we + Ae × ( pe - pa ) = C × m Thrust : Mass - specific Im pulse : tc A × ( pe - pa ) C = we + e = Is = m òF (t ) × dt t0 Weight - specific impulse : F I sp = m × g0 Thrust coefficient : mTr = F m Fc* pc × At C = = m m F = Fc* × CF = m × C * × CF * = pc × At × CF = m × C F F C CF = = = * * m×C pc × At C Rocket engine ther mod ynamic efficiency : hC = Cexp. Ctheor. Thrust chamber efficiency : * Cexp. hC* = * Ctheor. Nozzle efficiency : hC = F = hC* × hCF CF,exp. CF,theor. Thrust chamber performance Fc* = pc × At = m × C * 13.07.2012 REVA Seminar 6 The Rocket Equation • Describes Movement of • Differential form: a rocket in force-free space • Calculates velocity change achievable with • Integral form: a rocket geaturing a certain mass ratio and average specific Impulse 13.07.2012 REVA Seminar 7 Classification of Space Vehicles Space Vehicles Earthbound Systems Launch Vehicles Space Ferries Planetary Launch and Landing Vehicles Sounding Rockets Expendable Launch Vehicles Interorbital Ferries Atmosphere reentry Bodies Rocket Planes Reusable Launch Vehicles Space Tugs Manned Support Vehicles Unmanned Ballistic Missiles Ballistic Winged Landers Launchers 13.07.2012 REVA Seminar 8 Classification of Rocket Propulsion Systems • Origin of propulsion energy – Chemical – Nuclear – Solar • Propellants and their aggregate state – – – – Solid propellants Liquid propellants Hybrid engines Cold gases • Thrust level – High thrust (> engine weight) – Low thrust (< engine weight) 13.07.2012 REVA Seminar 9 Application of Rocket Engines 13.07.2012 REVA Seminar 10 Typical Performances of Rocket Engines 13.07.2012 REVA Seminar 11 Rocket Engine Performance Map specific impulse [m/s] thrust to mass [N/kg] acceleration [m/s] 13.07.2012 REVA Seminar 12 ∆V Requirement • The ∆V requirement of a space mission is dependent on: – Size and orbit of launch planet – Size and orbit of destination planet – Propulsion concept (thrust level, propulsion time) – Chosen trajectory and resulting flight time – Accuracy of orbit and attitude control system – Vehicle aerodynamics 13.07.2012 REVA Seminar 13 ∆V Calculation 13.07.2012 REVA Seminar 14 Typical ∆V Requirements 13.07.2012 REVA Seminar 15 Elements of a Space Transportation System Space Transportation System Vehicle (Launcher, Upper Stage, Transfer Vehicle, Lander) Ground Infrastructure Rocket Engine AI&T Buildings Tankage Propellant Production and Storage Facilities Structure Control Center Avionics Tracking and Data Relay Facilities Electrical and Hydraulical systems Launch Platform Payload 13.07.2012 REVA Seminar 16 Elements of a Rocket The take-off mass of a rocket consists of three major mass elements: • Structure and Engine(s) – – – – – – Body and tankage Engines and related equipment Non-usable propellant residuals Usable propellant reserve Recovery equipment (parachutes, wings, landing gear, etc.) Instrumentation and avionics • Propellants – Expected propellant consumption during flight – Propellants expended prior to lift-off • Payload 13.07.2012 REVA Seminar 17 Design Parameters • • • • According to the rocket equation a maximisation of the ratio between the initial mass m0 and the cut-off mass mc is required for a high velocity capability Thus 80% ÷ 90% of the initial mass of a rocket is propellant mass This requires an ultra-light structural design and small, efficient engines with a very high power density! Key design parameters of a rocket are: – The propellant mass fraction – The propellant ratio – The payload ratio 13.07.2012 REVA Seminar 18 Technological limits for a rocket • The performance of a single-stage rocket is limited by the technologically achievable values for the mass ratio R and the exhaust velocity C and the ∆V requirements of the mission: • Limits: – useful minimum payload mass fraction of – achievable propellant mass fraction of – today’s engines performance of m/s –minimum velocity increment to reach orbit l µ C0 Cvac >= = = = ∆V = 1% 0.90 4300 m/s 4600 9100 m/s • Thus, it is very difficult to design a one-stage launch vehicle! 13.07.2012 REVA Seminar 19 Technological Limits: Single-stage to Orbit (SSTO) me = mpropellant mpayload mpropellant + mstructure mpropellant mstructure mpropellant ³ 87,9% × m0 mstructure ³ 9,8% × m0 mpayload £ 2,3% × m0 13.07.2012 High Development Risk! REVA Seminar 20 Staging of a rocket • The problem can be overcome by "staging" the rocket which means distributing the total propellant mass over more than one tank for each propellant component and not further accelerating empty tankage by cutting it off • In theory a rocket with an infinite number of stages would provide a maximum payload ratio • Practically the number of stages is limited by the propellant mass fraction of each stage which increases with decreasing stage size because tanks and engines cannot be downsized linear • For transportation in orbits around Earth, 2-3 stages provide an optimum performance depending on the selected propellant combination and other design aspects 13.07.2012 REVA Seminar 21 Influence of staging on payload mass (example) One-stage design Two-stage design Assuming a launch vehicle based on following design data: Mission velocity requirement (Earth to orbit): Average specific Impulse of engines: Launch mass: Propellant mass fraction: 13.07.2012 ∆V=9200 m/s C=4400 m/s m0=100 Mg µ=0.9 REVA Seminar 22 Influence of staging on vehicle mass and payload One-stage design Two-stage design émù U 0 ³ DV = 9200 ê ú ësû m propellant émù U0 = 4600 ê ú ësû 2 m1 = m 2 = 0.90 ö æ ÷ ç 1 ÷ × m0 = 64847[kg] ç m propellant,1 = 1ç exp æ U1 ö ÷ ç ÷÷ ç è C øø è æ1 ö mstage,empty,1 = m propellant,1 × ç -1÷ = 7205[kg] è m1 ø m0,2 = m0 - m propellant,1 - mstage,empty,1 = 27948[kg] U1 = U 2 = æ ö ç ÷ 1 ç ÷ × m0 = 87643[kg] = 1æ ö U ç exp 0 ÷ ç ÷÷ ç è C øø è æ1 ö mstage,empty = m propellant × ç -1÷ = 9738[kg] èm ø ö æ ÷ ç 1 ÷ × m0,2 = 18123[kg] m propellant,2 = ç1ç exp æ U 2 ö ÷ ç ÷÷ ç è C øø è m payload = m0,2 - m propellant,2 - mstage,empty,2 = 7811[kg] m payload = m0 - m propellant - mstage,empty = 2619[kg] l= 13.07.2012 m payload = 0.0262 = 2.6% m0 l= REVA Seminar m payload = 0.0781 = 7.8% m0 23 Optimum staging of a launch vehicle • Optimum distribution of total ∆V between the stages of a rocket depends of specific impulses of stage engines and stage propellant mass fractions • For a two-stage vehicle, the payload mass fraction l of the rocket with respect to a given mission ∆V can be obtained from the following equation æ æ ö ö æ æ ö ö ç ç ÷ ÷ ç ç ÷ ÷ 1 1 1 ÷ ç1 ÷ l = lstage1 × lstage2 = çç × çç -1÷ +1÷ × ç × ç -1÷ +1÷ æ U1 ö ÷ æ U2 ö ÷ m1 m2 ç çç ç exp ç ÷ ÷ ÷÷ çç ç exp ç ÷ ÷ ÷÷ è C1 ø ø ø è è C2 ø ø ø è è è 13.07.2012 REVA Seminar 24 Optimum staging of a launch vehicle • For a rocket with the same average specific impulse and propellant mass fraction in each stage, the l Function has its maximum at U1=U2=∆V/2 • This means, that the first stage of a two-stage rocket should have a mass which is 3.6 times the mass of the second stage if the same technology is used in both stages • For a launch vehicle going from Earth‘s surface to an orbit the described theoretical optimum is additionally influenced by the ascend trajectory due to: – gravity and drag losses (changes theoretical ∆V distribution) – engine performance (C depends on ambient pressure) 13.07.2012 REVA Seminar 25 Optimum staging of a launch vehicle (Example) 13.07.2012 REVA Seminar 26