P - Industrial and Systems Engineering

advertisement

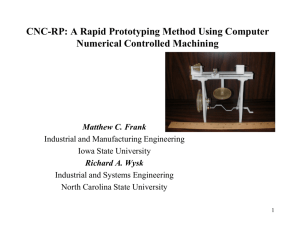

Conventional Methods for Rapid

Prototyping

Richard A. Wysk

Dopaco Distinguished Professor

Industrial and Systems Engineering

North Carolina State University

1

Agenda

• Why is Rapid Manufacturing (RM)

important in medicne?

• What is RM/RP?

• Limitations of RP

• Economics of RM/RP

• New directions in RM

• Sustainable RM

• Observations and conclusions

2

Broad focus -- Engineering

integration

ENGINEERING -- the planning, designing,

construction (manufacture), or management

of machinery, roads, bridges, etc..

3

Traditional Engineering

A Vision of Integrated

Engineering Systems (cont.)

INTEGRATE

– 1. to make or become whole or complete.

– 2. to bring parts together as a whole.

– 3. to remove barriers imposing segregation.

A Vision of Integrated

Engineering Systems (cont.)

INTEGRATED ENGINEERING

– planning, designing, construction and

management of a product.

Engineering Integration

Product Engineering

Process Engineering

Production Engineering

A Vision of Integrated

Engineering Systems (cont.)

INTEGRATION

ENGINEERING

– tools and techniques that

can be used to assist in

combining planning,

design, construction and

management of a product.

A Vision of Integrated

Engineering Systems (cont.)

• INTEGRATED ENGINEERING

– planning, designing, construction and management of a

product.

Engineering Integration

• Performing all business activities in unison

• Analyzing all engineering functions

concurrently

• Making wise real-time economic decisions

• Team concepts

What does this have to do with

Rapid Prototyping (RP)

•

Prototyping is critically important during product/process design

– Reduce time to market

– Early detection of errors

– Assist concurrent manufacturing engineering

•

Prototypes are used to convey a products’:

– Form

– Fit

Need for model

– Function

accuracy increases

•

Prototype building can be a time-consuming process requiring a highly skilled

craftsperson

– Time spent testing prototypes is valuable

– Time spent constructing them is not…

•

“Rapid Prototyping” (RP) methods have emerged

– (Solid Freeform Fabrication, Additive Manufacturing, Layered Manufacturing)

14

Rapid Manufacturing definitions

• Rapid Manufacturing (RM)

– Direct from CAD model without tooling

• No process engineering

– Short lead time

– Increased product fidelity

– Ready to use end products

• Additive processes

– Traditional Rapid prototyping (RP) process

• 3D printer, SLA, FDM, SLS…

– No geometry limitation

– Push button manner operation

15

– Restricted in material, accuracy, and surface finish

Image from http://www.tctmagazine.com/x/guideArchiveArticle.html?id=10839

Stereolithography (SLA)

Stereolithography is a common rapid

manufacturing and rapid prototyping

technology for producing parts with high

accuracy and good surface finish. A device

that performs stereolithography is called an

SLA or Stereolithography Apparatus.

Stereolithography is an additive fabrication

process utilizing a vat of liquid UV-curable

photopolymer "resin" and a UV laser to build

parts a layer at a time. On each layer, the laser

beam traces a part cross-section pattern on the

surface of the liquid resin.

Selective Laser Sintering (SLS)

SLS can produce parts from a relatively wide range

of commercially available powder materials,

including polymers (nylon, also glass-filled or

with other fillers, and polystyrene), metals (steel,

titanium, alloy mixtures, and composites) and

green sand. The physical process can be full

melting, partial melting, or liquid-phase sintering.

And, depending on the material, up to 100%

density can be achieved with material properties

comparable to those from conventional

manufacturing methods. In many cases large

numbers of parts can be packed within the

powder bed, allowing very high productivity.

Fused Deposition Modeling (FDM)

•

•

•

Fused deposition modeling, which is often referred to by its initials FDM,

is a type of rapid prototyping or rapid manufacturing (RP) technology

commonly used within engineering design. The FDM technology is

marketed commercially by Stratasys Inc.

Like most other RP processes (such as 3D Printing and stereolithography)

FDM works on an "additive" principle by laying down material in layers. A

plastic filament or metal wire is unwound from a coil and supplies material

to an extrusion nozzle which can turn on and off the flow. The nozzle is

heated to melt the material and can be moved in both horizontal and vertical

directions by a numerically controlled mechanism, directly controlled by a

Computer Aided Design software package. In a similar manner to

stereolithography, the model is built up from layers as the material hardens

immediately after extrusion from the nozzle.

Several materials are available with different trade-offs between strength

and temperature. As well as Acrylonitrile butadiene styrene (ABS)

polymer, the FDM technology can also be used with polycarbonates,

polycaprolactone, and waxes. A "water-soluble" material can be used for

making temporary supports while manufacturing is in progress. Marketed

under the name WaterWorks by Stratasys this soluble support material is

actually dissolved in a heated sodium hydroxide solution with the

assistance of ultrasonic agitation.

Laminated Object Manufacturing

(LOM)

Laminated Object

Manufacturing (LOM) is a

rapid prototyping system

developed by Helisys Inc. (Cubic

Technologies is now the

successor organization of

Helisys) In it, layers of adhesivecoated paper, plastic, or metal

laminates are successively glued

together and cut to shape with a

knife or laser cutter.

Electron Beam Melting (EBM)

•

•

Electron Beam Melting (EBM) is a type of rapid

prototyping for metal parts. The technology

manufactures parts by melting metal powder layer

per layer with an electron beam in a high vacuum.

Unlike some metal sintering techniques, the parts

are fully solid, void-free, and extremely strong.

Electron Beam Melting is also referred to as

Electron Beam Machining.

High speed electrons .5-.8 times the speed of light

are bombarded on the surface of the work material

generating enough heat to melt the surface of the

part and cause the material to locally vaporize.

EBM does require a vacuum, meaning that the

workpiece is limited in size to the vacuum used.

The surface finish on the part is much better than

that of other manufacturing processes. EBM can be

used on metals, non-metals, ceramics, and

composites.

Types of RP Systems

Prototyping Technologies

Base Materials

Selective laser sintering (SLS)

Thermoplastics, metals powders

Fused Deposition Modeling (FDM)

Thermoplastics, Eutectic metals.

Stereolithography (SLA)

photopolymer

Laminated Object Manufacturing

(LOM)

Paper

Electron Beam Melting (EBM)

Titanium alloys

3D Printing (3DP)

Various materials

So what’s the problem?

• Rapid Prototyping?

physical models

– Technology for producing accurate parts directly from CAD

models in a few hours with little need for human intervention.

– Pham, et al, 1997

• Prototype?

– A first full-scale and usually functional form of a new type or

design of a construction (as an airplane)

– Webster’s, 1998

• Model?

– A representation in relief or 3 dimensions in plaster, papier-mache,

wood, plastic, or other material of a surface or solid

– Webster’s, 1986

How can we automatically create toolpath and fixture plans

for CNC?

22

Problems with Additive RP

• Long processing times

• Energy use

• Expensive product ?!?

– Not intended as a production technique

• Functional product ?!?

– May not quite meet material or dimensional

requirements

23

CNC Machining

Computer numerical control, and refers

specifically to a computer "controller"

that reads G-code instructions and drives

a machine tool, a powered mechanical

device typically used to fabricate

components by the selective removal of

material. CNC does numerically directed

interpolation of a cutting tool in the

work envelope of a machine. The

operating parameters of the CNC can be

altered via a software load program.

Economics

Product cost = engineering cost + materials

cost + manufacturing cost

This is the cost for all parts that will be made and sold.

Product cost /part = engineering cost / total #

of parts + materials cost / part +

manufacturing cost / part

This is the cost for each part that will be made and sold.

Engineering cost

• Product design (Ced)

– Cost of engineering design

• Process design (Cpc)

– Cost of process planning

• How is the part to be made

– Cost of fixtures and tooling

• Production design (Cpd)

– Cost of setting up production

26

Material cost

• In most cases this is somewhat dependent

of the number of parts

– Economies of scale

– Efficiencies of scale

• Additive or subtractive

– Fractional or bulk materials

27

Engineering cost

CE = Ced / nt + Cpc / nt + Cpd / nb

total parts

total parts parts in a batch

28

Manufacturing cost

• One time costs

– Process planning and design

– Fixture engineering and fabrication

• Set up cost (Cset)

– Cost to set up a process

• Processing cost (Cpsc)

– Cost of processing a part

• Production cost (Cpdc)

– Cost of tooling and perishables

29

Manufacturing cost

CM = Cone / nt + Cset / nb + Cpsc +

Total parts

parts in a batch

each part

Cpdc / ntool

tool cost by parts/tool

30

Economic Analysis

• A general cost model

Eng

Costs

Materi

al

Costs

Manuf.

Costs

Planning

Tooling

Design

Process

Total

Cost

Subtractive

Process

Additive

Process

31

So how can engineering costs be

reduced for CNC machining?

Machine cost

Fixture cost

Process planning cost

• CNC-RP Method: A part is machined on a 3-Axis mill with a

rotary indexer and tailstock using layer-based toolpaths from

numerous orientations about an axis of rotation.

End mill

Round stock

Axis of rotation

Table

Rotary indexer

Opposing

3-jaw chucks

STEPS TO CREATE A PART

( MT. Bike Suspension Component)

2. Second orientation is machined

(Side View)

1. First orientation of part section is machined 3. Third orientation is machined

Rotate Stock

2. Second orientation is machined

4. Fourth orientation is machined

STEPS TO CREATE A PART

( MT. Bike Suspension Component)

5. Left support section is machined

7. Temporary supports are removed

6. Right support section is machined

8. Part is severed from stock at supports

Process/fixture planning time: Minutes

Processing time ~20 hours

Part fixtured with final 2 sacrificial supports

Part fixtured with final 2 sacrificial supports

4”

Material: Steel

4”

Layer depth: 0.001” (0.025mm)

Finished Steel Part

Finished Steel Part

Setups/Orientation Planning

50o

155o

228o

50

o

155o

335o

228o

VISIBILITY

335o

MACHINABILITY

(for a given tool geometry)

Non-machinable

Non-machinable

Region

Region

•

•

Methodology

Overview:

– Visible surfaces of the part are machined from each orientation about an axis of

rotation

– Long, small diameter flat end tool with equal flute and shank diameter used.

– Sacrificial supports (temporary features) added to the solid model and created inprocess

– Begin with round stock material, clamped between two opposing chucks

Example:

z

z

y

x

y

Toolpath layers at 0º orientation

z

y

Toolpath layers at 180º orientation

z

y

x

38

Research Problems

•

Setup/Orientation

– How many rotations (setup orientations) about the axis of rotation are required?

– Where are they?

•

Toolpath planning

– For each orientation, how can we automatically generate toolpaths?

– What diameter and length tools should be used?

– In what order should the toolpaths be executed?

•

Fixture planning

– How can we automatically generate sacrificial supports?

– What diameter and length should they be?

39

Rapid Prototyping

•

Basics:

–

–

Solid model (CAD) is converted to STL format

•

Facetted representation where surface is approximated by triangles

•

Intersect the STL model with parallel planes to create cross sections

Create each cross section, adding on top of preceding one

z

y

x

CAD (ProE)

STL

“slicing”

operation

2-D cross

section

40

Rapid Prototyping

•

•

Fixtures are created in-process (Sacrificial Supports)

– Secure model to the build platform

– Support overhanging features

Remove fixture materials in post-process step

Model material

Support material

Build Platform

FDM Model with/without supports

41

Determining the number of rotations

•

A problem of tool accessibility

•

Approximated as a problem of visibility (line of sight)

•

A Visibility map is generated via a layer-based approach

•

Tool access is restricted to directions in the slice plane (2D problem)

•

Goal is to generate the data necessary to determine a minimum set of rotations required to

machine the entire surface

Set of segments on a slice visible

from one tool access direction

42

Approaches to 2D visibility mapping

• Shortest Euclidean paths - Lee and Preparata, 1984

• Convex ropes - Peshkin and Sanderson, 1986

• 2D visibility cones - Stewart, 1999

Issues:

• Computing S.E.P.s/VCs for

polygons with holes

• Granularity of STL files, may

need to add collinear points to

polygon segments

• Would need to retriangulate

43

Solution approach

• Visibility for each polygonal chain is determined by calculating

the polar angle range that each segment of the chain can be seen.

• Since there can be multiple chains on each slice, we must consider

the visibility blocked by all other chains.

Θb

Θc

Θb

Θa

Θa

(a) Visibility for the segment=

[Θa,Θb,]

Θd

(b) Visibility for the segment=

[Θa,Θb,], [Θc,Θd,]

44

Step one: Visibility with respect to own chain

•

We have a polygon P and its convex hull S

•

For any point Pi not on S, the visible range can be found by investigating points from the

adjacent CCW convex hull point to the adjacent CW convex hull point

•

These points will be denoted the “left” and “right” convex hull points of Pi, LCHP(Pi) and

RCHP(Pi), respectively.

•

It is only necessary to calculate the polar angles from Pi to the points in the set [LCHP,

RCHP], excluding Pi.

S1 : [ LCHP, Pi 1 ]

The set is divided into, S1 and S2 where:

S 2 : [ Pi 1 , RCHP ]

•

LCHP

RCHP

Pi+1

Pi

P:

S:

,

not

visible

RCHP

LCHP

Pi-1

Pi+1

Pi

45

•The visible range for a point is bounded by the minimum polar angle from Pi

to points in S1 and the maximum polar angle from Pi to points in S2.

•This is the visible range for the point Pi with respect to the boundary of its

own chain, and is denoted V(Pi).

Where:

V ( Pi) [ Max( Pi X ), Min ( Pi Y ]

X S 2

Y S 1

V(Pi): [43.82 ,121.31]

V(Pi)

S1

Pi

S2

46

• Consider the segment defined by points in P, u and v, where:

u: Pi and v: Pi+1

• The intersection of visibility ranges for the points u and v and the 180º range

above the segment define a feasible range of polar angles in which the segment

could be reached.

(Vu Vv ) [ RV u , LVu ] [ RV v , LVv ] [ RV v , LVu ]

RVv

LVv LVu

RVu

u-1

vu

v+1

u

uv

v

•The sets S1 and S2 are redefined:

S1 : [ LCHP (u ), (u 1)]

S 2 : [(v 1), RCHP (v)]

•The ends of the visibility range are: RV (uv) [ Max(vx)]

xS 2

LV (uv) [Min (uy)]

yS1

47

Problem Surfaces

LV

I1

u v I2

u v I2

RV

(a)

RV

I1

LV

(b)

RV

LV

RV

LV

I2

I1

u

(c)

I2

I1

v

u

v

(d)

(a) RV is outside of the 180º range, (b) Both RV and LV are out of the 180º range, (c)

No visibility due to overlapping, (d) Visibility to the entire segment is not possible

since RV > LV.

48

Step two: Visibility blocked by all other chains on the slice

•

V( uv)j* is the visibility with respect to the chain j on which

denoted j*.

•

For all obstacle chains

denoted VB( uv )j.

•

The set of visible ranges for the segment is defined:

j J \ j *

uv

resides,

, the polar range blocked by the chain is

VIS (uv) V (uv) j* VB(uv) j

•

Visibility blocked to the segment uv is the union of the visibility blocked by

chain j to point u and the visibility blocked by chain j to point v, intersected

with the 180º range above segment uv

•

The set of angles blocked to the segment where:

VB(uv) j {[[VB(u ) j ] [VB(v) j ]] [uv, vu]}

•

The set of angles blocked to points u and v where:

VB(u ) j [ RB u , LBu ]

VB(v) j [ RB v , LBv ]

49

• Considering the condition that

blocked visibility is only for blockage

in the 180º range above the segment,

it can easily be seen that the set:

(VBu VBv ) [ RB u , LBu ] [ RB v , LBv ] [ RB u , LBv ]

LBu

RBv

LBv

RBu

• RBu is simply the minimum polar

angle from u to all points on the

blocker chain

• LBv is the maximum polar angle from

v to all points on Pj, where Pj is the

set of points for the blocker chain.

RBu [ Min (ux)] LBv [ Max(vy)]

xP

j

uv

yPj

50

Recall: VIS (uv) V (uv) j*

VB(uv)

j

•For each segment the collection of visible ranges given in polar angle about the

axis of rotation:

VIS tjk : [ a , b , ]1 , [ a , b , ] 2 ,...[ a , b , ]r

where: rMAX = n

•From the data in [VIS] we can formulate a set corresponding to the segments visible

from a given angle.

s {( SEGtjk ) ( a s b ) for some range, [ a , b ] r VIS tjk }

VIS1,1,1 (Θa,Θb)1, (Θa,Θb)2, …(Θa,Θb)n

VIS2,1,1 (Θa,Θb)1, (Θa,Θb)2, …(Θa,Θb)n

Θ1

Θ2

SEG1,1,1, SEG2,1,1, SEG1,5,3…

(Θa,Θb)1, (Θa,Θb)2, …(Θa,Θb)n

Θs

SEG

tjk. . . .

.

.

.

.

VIStjk

.

.

.

.

.

.

.

.

.

VISqnp (Θa,Θb)1, (Θa,Θb)2, …(Θa,Θb)n

.

.

.

.

.

.

Θ359

SEG13,1,2, SEG14,1,2, …

.

.

.

.

.

SEGtjk. . . .

The Minimum Set Cover problem:

Given: A collection of subsets Θs of a finite set SEG (the set of all segments)

Solution: A set cover for SEG, i.e., a subset S’ S such that every element in SEG belongs to at

least one member of Θs for s S ' .

51

l

Visibility – Machinability Analysis

Non-machined regions

Inch

Non-machined regions

50o

Predicted vs. Measured Machinability on sample

part

335o

(b) Machined “Jack”

CNC RP Methodology

•

Creation of complex parts using a series of thin layers (slices) of 3-axis

toolpaths generated at numerous orientations rotated about an axis of the part

•

Toolpath planning based on “layering” methods used by other RP systems

•

“Slice” represents visible cross-sectional area to be machined about

(subtractive) rather than actual cross section to be deposited (additive)

•

Slice thickness is the depth of cut for the 2½-D toolpaths

•

Tool used is a flat end mill cutter with equal flute and shank diameter (or

shank diameter < flute diameter)

•

Stock material will be cylindrical, therefore toolpath z-zero location will be

same for all orientations

53

Methodology (cont.)

Flat end mill cutter

“Staircase” effect

Region not visible from

current orientation

Set of visible slices from

current orientation

Toolpath planning using this approach is done with ease in current CAM

software (MasterCAM rough surface pocketing)

54

Methodology (cont.)

• Fixturing accomplished through temporary feature(s) (cylinders)

appended to the solid model prior to toolpath planning

• Cylinders attached to solid model along the axis of rotation

• Incrementally created during machining operation as the model is

rotated

• Model remains secured to stock material then removed (similar to

support structures in current RP methods)

55

Fixture Planning

•

•

•

•

•

Approach uses “sacrificial supports” to retain the prototype within the stock material

Round stock clamped between opposing chucks

As prototype is rotated b/w toolpaths sacrificial supports are incrementally created

Supports cut away to remove finished part

Current approach assumes model surfaces exist along axis of rotation

– Only one fixture support cylinder used on each end

– No change to visibility calculations

Problems:

Where do cylinders begin/end?

What diameter?

56

Wire EDM Rapid Prototyping

• Medical RP, one of the major territories for RP application

– Manufacturing of dimensionally accurate physical models of

the human anatomy derived from medical image data using a

variety of rapid prototyping (RP) technologies

– CNC-RP?

• Typical bio/medical Material

– Titanium

– Stainless steel

– Cobalt alloy

• Advantage of Wire Electric

Discharge Machining(WEDM)

– Cut any electrical conductive material regardless hardness

– Ignorable cutting force

– Capable to produce complex part

Satisfy material requirement

• WEDM is different from traditional

machining process

Point contact

Linear

Surface

• Wire EDM

• Laser

• Waterjet

• Visibility problems are different

Can we see it?

Can we access it?

Tool orientation

wire orientation

– “Can we see it” vs. “Can we access it using a

straight line”

Wire EDM RP

Can we make it?

How to make it?

(setup)

How to make it?

(Toolpath, NC code)

Wire EDM RP

• Investigate the manufacturability

– Part Geometry

– 6-axis Wire EDM

– Rigid machining part

– No internal through features

Can we make it?

How to make it?

(Toolpath, NC code)

• Find the B-axis orientation

– Try to minimize number of B-axis orientation

Wire EDM RP

• Toolpath generation

How to make it?

(Toolpath, NC code)

– Discrete Toolpath for B-axis and other 5-axis

– STEP-NC

• Fixture Design

– Ignorable cutting force : Clamp part

RP versus CNC-RP and WireEDM-RP

•

•

RP processes are very flexible and very capable

However:

– RP processes rely on specialized materials

– Limited accuracy in some cases

Functional prototypes?

•

CNC Machining is:

– Subtractive process

– Accurate

– Capable of using many common manufacturing materials

•

CNC Machining is NOT:

– Automated

– Easily usable except by highly skilled technicians

•

CNC machining cannot create all parts

• No hollow parts

• No severely undercut features

The time consuming tasks of process and fixture planning are major factors which

prohibit CNC machining from being used as a Rapid Prototyping Process

– Wang et al, 1999

•

63

Conclusions

• For prototyping, the process is dominated by engineering

cost

– Product engineering, Process engineering, production engineering

• RP has come a long way

– Usable products

– Process and production engineering coasts are minimal

• Conventional methods are on their way back

– CNC RP

– Wire EDM RP

64

Example- The “Jack”

Material: 6061 Aluminum

Tool: 1/8” Flat end mill

Machine: Haas VF-O, 3-Axis mill

Layer thickness: 0.005”

Speed: 7500rpm, Feed: 350 ipm

Machining time: 3 hours

Prototype after

2 of 4 rotations

1”

Toolpath and Fixture planning time: < 15 minutes!

65

66

Questions?!?

68

69

70