JHA Training - Midwest Water Analysts Association

advertisement

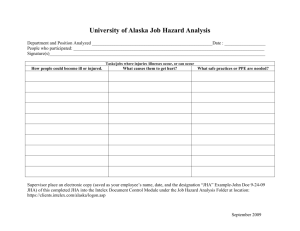

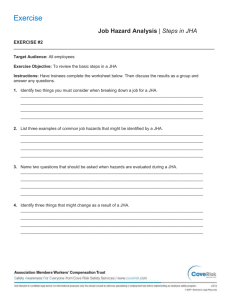

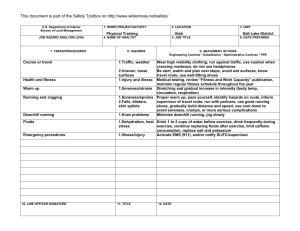

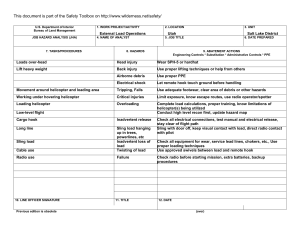

Job Hazard Analysis (JHA) Training Robert Evangelisti, P.E., CEA, CHMM, CSP Occupational and Environmental Safety & Health University of Wisconsin-Whitewater Midwest Water Analysts Association Expo 2016 Winter Meeting January 29, 2016 3:20 PM South Room Kenosha, WI Purpose of the Talk n n n Discuss the Features and Benefits of Job Hazard Analysis (JHA) Help you understand how to conduct a JHA at your site Help you understand the information gathered during the JHA process to reduce hazards, incidents and injuries 2 Topics n n n n n n n n n Job Hazard Analysis (JHA) Terms Conducting a JHA Job Risk Inventory – Form Job Hazard Analysis – Form Job Hazard Analysis – Review JHA - Other Applications Summary To learn more about JHAs 3 Job Hazard Analysis (JHA) - 1 n A method for studying a job in order to: • Identify hazards • Assess risk • Develop controls, actions, solutions, corrective actions - all have the same goal in the end – protect people • Controls: • Engineering - best • Administrative - training, procedures, rules, etc. • PPE – last line of defense 4 Job Hazard Analysis (JHA) - 2 n JHA can also be called: – – – – n n n Job Risk Assessment (JRA) Job Safety Analysis (JSA) Task Hazard Analysis (THA) Risk Analysis and Evaluation (RAE), etc. No OSHA Standard requiring JHAs JHAs can be expanded to become a Job Safety and Environmental Analysis (JSEA) JHAs are an important part of risk management. 5 Occupational Safety & Health Act n General Duty Clause § 5(a): – (1) “Each employer … shall furnish … employment … free from recognized hazards that are causing or likely to cause death or serious physical harm to his employees” – (2) “shall comply with … safety and health standards…” – 29 USC 654(a) n Goal § 6(b)(5): – To ensure that “no employee will suffer material impairment of health or functional capacity” from a lifetime of occupational exposure – 29 USC 655(b)(5) 6 Terms - 1 n n HAZARD: An existing or potential condition that can result in injuries, property damage or other losses RISK: The likelihood, high or low, that someone or something will be harmed by a hazard 7 Terms - 2 n SAFETY: Protected from or unlikely to cause danger, risk, or injury. 8 EHS Priorities 1. 2. 3. 4. Protect people — employees, temporary workers, contractors, suppliers, and visitors Protect the environment (natural and human) Protect the business from interruption and loss of jobs Protect the property from damage Your goal is to keep people safe: even one accident or incident is one too many. 9 Job Hazard Analysis (JHA) n JHA consists of four (4) phases: 1. Determine the job to be analyzed based on potential hazards - can also call “risk.” 2. Break down the job into basic steps and the sequence in which those steps are performed. 3. Evaluate each step for safety, health and environmental hazards. 4. Recommend solutions for each hazard identified. – Could also include environmental risks, aspects, impacts, etc. 10 JHA Benefits – Sales Job n If hazards can be identified, anticipated, and controlled, JHAs can reduce incidents, injuries, illnesses by: – Assessing operations in the work place – Correcting uncontrolled hazards – Establishing proper procedures – Establishing OTJ training using JHAs – Showing management’s commitment to a safe workplace 11 Job Hazard Analysis - Job n n In a JHA, a job is a specific set of activities which accomplishes a work goal. It is NOT a: • title • position • occupation 12 Conducting a JHA - Phase 1 n n Determine jobs to be analyzed. A JHA should be performed on jobs that address the following questions: 1. Has the job caused accidents in the past? 2. Has the job caused near misses in the past? 3. Does the job have a high potential to cause severe injury, illness, property damage or environmental degradation? 4. Has the job had a high accident/incident frequency? 5. Does the job have a possibility of accident/incident? 6. Has the job undergone changes in processes, equipment or procedures? 7. Could the job result in a spill, release, fire, explosion, violation, etc.? 8. Is the job newly created? 13 Conducting a JHA - Phase 1 n Look at: A. B. C. D. n n Exposure concerns Potential consequences Accident frequency Operation or equipment change Rate the job: 0, 1, 2, 3, 4 While this may be a subjective process, try to reach group consensus. • While the group could be a 2-person team, try to get consensus of entire team. n Document on a Job Risk Inventory – Form 14 Job Risk Inventory - Form JOB RISK INVENTORY Department: Completed By: Date Originated: Date Revised: INSTRUCTIONS: This form should be completed by department managers, supervisors or key operators. Record all jobs performed in your department. For each job, assign a risk rating (0-4) in each of the four categories (A-D). Jobs rated a “4” in any single category, or jobs with a total score of “8” or higher, should undergo a Job Hazard Analysis as soon as possible. A. EXPOSURE CONCERNS: Mechanical: Machine guarding, moving parts, energized equipment Chemical: Hazard Rating Ergonomic: Lifting, bending, straining, repetitive motion Environmental: Chemical releases Physical: Noise, heat, light 0=None 1=Slight; Haz.Code 1 2=Moderate; Haz. Code 2 3=Major; Haz. Code 3 4=Fatal or catastrophic; Haz. Code 4 B. EXPOSURE CONSEQUENCES C. ACCIDENT/INCIDENT FREQUENCY (Potential) 0=No injuries/illnesses/chemical releases are likely to occur 1=First Aid treatments or releases with minor consequences could occur 2=Medical treatments or releases with moderate consequences could occur 3=Medical treatments with lost time or releases with serious consequences could occur 4=Death or releases with catastrophic consequences could occur JOB BEING ANALYZED (History within last five years) 0=None 1=One accident/incident has occurred 2=Two accidents/incidents have occurred 3=Three accidents/incidents have occurred 4=More than three accident/incident have occurred D. OPERATION OR EQUIPMENT CHANGE 0=None 1=Minor change: rearrange equipment 2=Moderate change: new chemicals but same formula; new tools 3=Major change: new equipment, new product or formula change 4=New Job RISK RATING TOTAL SCORE 1. ______________________________________________________________ A)_____B)_____C)_____D)_____ _____ 2. ______________________________________________________________ A)_____B)_____C)_____D)_____ _____ 3. ____________________________________________________ __________ A)_____B)_____C)_____D)_____ _____ 4. ______________________________________________________________ A)_____B)_____C)_____D)_____ _____ 5. ______________________________________________________________ A)_____B)_____C)_____D)_____ _____ 6. ______________________________________________________________ A)_____B)_____C)_____D)_____ _____ 7. ______________________________________________________________ A)_____B)_____C)_____D)_____ _____ 8. ______________________________________________________ ________ A)_____B)_____C)_____D)_____ _____ 9. ______________________________________________________________ A)_____B)_____C)_____D)_____ _____ 10. ______________________________________________________________ A)_____B)_____C)_____D)_____ _____ 15 Conducting a JHA - Phase 2 n n Break down the job into basic steps. The steps should: • Describe what is done now: • Not how it was done in past. • How should it be done? • Be in sequential order • Avoid too much detail - 5-15 steps may be adequate. • Avoid generalities - do not omit steps or use vague descriptions. • Begin with an action verb, e.g., remove, attach, etc. 16 Job Hazard Analysis – Form 17 Conducting a JHA - Phase 2 n Determine basic job steps through direct observation: • Select a job and an employee who performs that job. • Brief the employee on the purpose of the observation – get his/her input. • Study the job, not the performance. • Write down everything performed by the employee. Pay special attention to changes in activity. • Review your break-down with the employee. • Record the break-down of steps on the JHA form. 18 Conducting a JHA - Phase 2 n Determine basic job steps using discussion method: • Select a group of employees that perform the job in question. • Ask the group to explain their activities. • Break down the job steps on the JHA form. • Direct observation may be preferable. 19 Conducting a JHA – Phase 3 n Evaluate each step for hazards: • Examine each step for actions or conditions that could possibly cause an accident. • The goal is to identify all hazards, whether they are a result of an unsafe act, behavior, or condition. • May have more than one hazard per step • Can the hazard be eliminated? • If it cannot be eliminated, it needs to be controlled. 20 Conducting a JHA – Phase 3 n n Hazards are usually either chemical, physical/mechanical or ergonomic. Ask: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Is the employee at risk of exposure to hazardous substances and conditions, such as chemicals, gasses, mists, fumes, vapors, heat, noise, radiation or containment? Is the employee exposed to hazardous tools and equipment? Is the employee in danger of being struck by a falling or flying object? Can the employee strain himself or herself by pushing, pulling, lifting, bending or twisting? Can the employee fall, slip or trip? Can the employee get caught in, by or between objects? Is there danger of explosion, fire, and electrical shock? Is the ventilation and lighting adequate? Are there repetitive motion activities? Could the job result in a spill, release, waste generation, etc.? Could the job result in property damage, loss, etc.? Could the job result in a governmental violation, etc.? 21 Conducting a JHA – Phase 3 n Identifying hazards – What could go wrong? – What are the consequences? – How could it happen? – Are there contributing factors? – What is the likelihood of occurrence? – What is the significance of occurrence? 22 Conducting a JHA – Phase 4 n Recommend solutions for the hazards identified: • Procedure based: The job might be performed in another way. • Environment based: The work environment could be made safer or alternative tools/equipment could be used. • Method based: Less hazardous materials and PPE could be used. • Frequency based: The frequency of a step could be reduced. • Remember your control hierarchy: • Engineering • Administrative • PPE 23 Conducting a JHA – Phase 5 n n Completed JHAs should be reviewed by a supervisor, department head and EHS professional. Review completed and approved JHAs with all employees performing the job. 24 JHA - Review n JHA Consists of four (4) phases: 1. Determine the job to be analyzed based on potential hazards (can also call “risk”). 2. Break down the job into basic steps and the sequence in which those steps are. performed. 3. Evaluate each step for safety, health and environmental hazards. 4. Recommend solutions for each hazard identified. 25 JHA – “Other” Applications n Training tool: • Inform new employees how to perform in safe, efficient way. • Educate new employees about basic job steps. • Instruct employees involved in irregular or infrequent jobs. n n n Improve job methods to enhance productivity. Increase employee safety awareness. Include environmental risks (JSEA) 26 Weaknesses in JHA n Can miss environmental exposures – Can be overcome if aware of this limitation n Limited by the knowledge of people doing the JHA – Practice makes perfect. Summary - 1 n Job Hazard Analysis (JHA): – A method for studying a job in order to identify existing or potential hazards and develop solutions to eliminate or minimize those hazards n No OSHA Standard for JHA 28 Summary - 2 n Consider doing a JHA for every “routine” task. – Keep it simple. n 1. 2. 3. n Eventually will have a library of JHAs List the tasks: step-by-step List the hazards List the controls Revise JHA: – If there is an incident involving the job – If you realize step, hazard, or control missing 29 Summary - 3 n To be most effective, JHAs should be: • Understood, used and followed • Shared • Updated • Reviewed immediately in the event of an accident as a part of the incident investigation • Revised as appropriate • Consider: • Writing a JHA procedure (with forms) • Conducting JHA training • These can help institutionalize the JHA process. 30 Summary - 4 n n n n n n n n n Job Hazard Analysis (JHA) Terms Conducting a JHA Job Risk Inventory – Form Job Hazard Analysis – Form Job Hazard Analysis – Review JHA - Other Applications Summary To learn more about JHAs 31 To learn more about JHAs n OSHA 3071: Job Hazard Analysis 32 Contact Information Robert Evangelisti, P.E., CEA, CHMM, CSP University of Wisconsin-Whitewater OESH Department Hyland Hall - 3423 800 West Main Street Whitewater, WI 53190 UWW: 262-472-5423 Cell: 262-909-4299 evangelr@uww.edu 33