Valefi pour Bacou Dalloz

advertisement

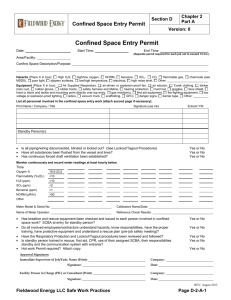

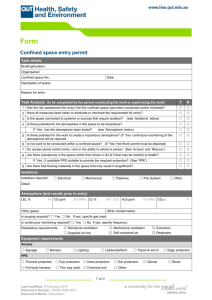

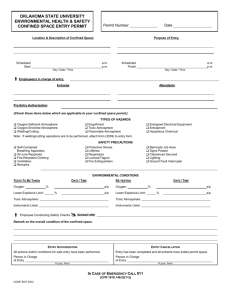

MILLER FALL PROTECTION Confined Space Presentation Bob Wengryn Fall Protection Sales Manager 1 BACKGROUND District Sales Manager 16 Years Experience Competent Person Certification OSHA 30 Hour Certification Confined Space Certification FEATURED SPEAKER; ASSE, MBA, AGC, SIA, W.V. SAFETY SHOW, W. P.A. SAFETY SHOW, AIST 2 TOPICS TO BE COVERED Why Such A Big Issue? Confined Space Program Requirements What Is A Confined Space / Identify Evaluate Hazards Establish Protection Procedures To Control Hazards Written Program & Permit Process For Entry 3 WHY SUCH A BIG ISSUE? Confined Space Hazards that cause fatalities 47% Air (Oxygen, Gases, Vapors) 21% Drowning (Engulfment) 19% Toxic (Liquids, Vapors, etc above PEL) 10% Blunt Force Trauma 2% Electrocution (Mostly due to objects brought in) 1% Burns NOTE: 60% OF THE ANNUAL CONFINED SPACE DEATHS ARE NOT THE ENTRANT. 4 CONFINED SPACE PROGRAM REQUIREMENTS 5 • • Identify all confined spaces • Establish protection procedures to control hazards • Set up written program and permit procedures for entering Evaluate confined spaces for hazards WHAT IS A CONFINED SPACE? Is large enough and so configured that an employee can bodily enter and perform assigned work; And Has limited or restricted means for entry or exit; And Is not designed for continuous employee occupancy 6 PERMIT REQUIRED CONFINED SPACE A confined space that has one or more of the following: Contains or has a potential to contain a hazardous atmosphere; Contains a material that has the potential for engulfing an entrant; Has an internal configuration such that an entrant could be trapped or asphyxiated; or Contains any other recognized serious safety or health hazard 7 Examples of Confined Spaces Open-Topped Water Tanks Sewer and Underground Pump Stations Wastewater Holding Tanks Degreasing Tanks Grain Silos Sawdust Silos Railroad Tank Cars Tanker Trucks Trenches / Trench boxes 8 EVALUATE HAZARDS – ATMOSPHERIC TESTING Tested before an employee enters the space Calibrated direct-reading instrument O2, Flammables, Toxics Must protect employees from the hazardous atmosphere before any entry takes place Employee or authorized representative shall be provided an opportunity to observe the pre-entry testing Periodic testing required 9 OSHA’s STANCE ON CALIBRATION What does OSHA accept as a "calibrated" direct reading instrument required by paragraph (c)(5)(ii)(C) for entrants to test the atmosphere for permit space entry? A testing instrument calibrated in accordance with the manufacturer's recommendations meets this requirement. The best way for an employer to verify calibration is through documentation 10 Calibration: The Key to Accurate Readings Calibration refers to an instrument’s measuring accuracy relative to a known concentration of gas. Gas detectors measure the concentration of a gas in an air sample by comparing the sensor’s response to the response generated by a calibration gas of a known concentration. The instrument’s response to the calibration gas serves as the measurement scale or reference point. 11 Calibration: The Key to Accurate Readings Calibration drift: when an instruments reference point has shifted resulting in unreliable data Caused by: Gradual sensor degradation Chronic exposures to extreme temperatures and humidity Exposure to high (over range) concentrations of gas Exposure to LEL sensor poisons Harsh storage and operating conditions 12 EVALUATE HAZARDS - RETRIEVAL Horizontal entry Vertical entry How many in space? Obstacles? 13 CONTROLLING HAZARDS Specify acceptable entry conditions Isolating the permit space (29 CFR 1910.147 LOTO) Providing barriers to prevent entry Verifying acceptable entry conditions Purging, making inert, flushing or ventilating the permit space. 14 Reclassifying Confined Spaces Permit Spaces can be made non-permit if ALL hazards are eliminated For as long as the non-atmospheric hazards remain eliminated. Control of atmospheric hazards through forced air ventilation does not constitute elimination of the hazards – MUST MONITOR!!!! 15 WRITTEN CONFINED SPACE PROGRAM Implement measures to prevent unauthorized entry Identify and evaluate hazards in permit space Test atmospheric conditions in the permit space Eliminate or control hazards in space Identify employee job duties Provide and maintain PPE and require employees to use it Ensure that at least one attendant is stationed outside the permit space for the duration of entry operations 16 Written Confined Space Program Coordinate entry operations when employees of more than one employer are in the permit space Procedures for summoning rescue and emergency services Preventing unauthorized personnel from attempting rescue Establish a system for the preparation, issue, use and cancellation of entry permits Review established entry operations annually 17 CONFINED SPACE ENTRY PERMIT 18 • Location of space • Scope of work • When work will be done • How long work will take and duration of permit • Names of all team members and duties SAFETY INFORMATION ON PERMIT 19 • Atmospheric testing results: initial and follow up • Hazard control actions taken • Special permits such as hot work. BASIC EQUIPMENT ON PERMIT 20 • PPE • Communication devices • Fall protection devices • Structures or modifications needed • Rescue equipment • Alarms • Non-sparking tools • Intrinsically-safe lighting RESCUE INFORMATION ON PERMIT • Identity of rescue team • How to summon the rescue team • 21 Required rescue equipment THE CONFINED SPACE ENTRY TEAM 22 • Attendants • Entrants • Entry supervisor • Rescue Personnel ATTENDANT DUTIES 23 • Keep people and hazards away • Monitor and communicate with entrants • Know signs of a problem • Order entrants out if needed • Summon rescue team • Begin non-entry rescue • Never enter confined space ENTRANT DUTIES 24 • Know hazards of space • Understand information on permit • • • • • Ensure listed hazards are controlled Wear required safety equipment and PPE Recognize signs of a problem Stay in contact with attendant Get out at first sign of a problem ENTRY SUPERVISIOR DUTIES • • • • • • 25 Authorizes entry Makes sure permit is complete Sees that tests and procedures are done Determines that team members and equipment are in place Oversees follow-up tests Terminates entry permit when work is finished or if problem develops RESCUE AND EMERGENCY SERVICES 26 • Know actual confined spaces and potential rescue problems • Trained in first aid and CPR • Practice regularly at spaces • Can respond to emergencies “in a timely matter” Rescue Equipment Non-Entry Rescue FIRST!!!! Retrieval systems shall be used Wristlets or full body harness, with a retrieval line attached at the center of the entrant's back near shoulder level Mechanical device for vertical distances more than 5 feet (1.52 m) deep 27 CONTRACTOR’S MUST BE INFORMED OF: Permit spaces and entry requirements Any identified hazards The employer’s experience with the space Precautions or procedures to be followed Coordinating entry between two or more contractors Debriefing at the conclusion of entry operations 28 CORRECT? 29 Review Why Such a Big Issue? Confines Space Program Requirements What is a Confined Space / Identify Evaluate Hazards Establish Protection Procedure to Control Hazards Written Program and Permit Process for Entry 30 Thank You! Bob Wengryn Phone: 412-580-9862 Email: bwengryn@sperianprotection.com The World Leader in Personal Protective Equipment 31