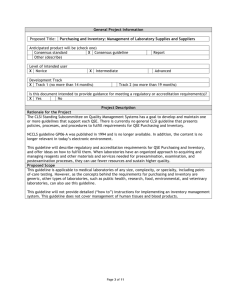

Developing a Quality Management System

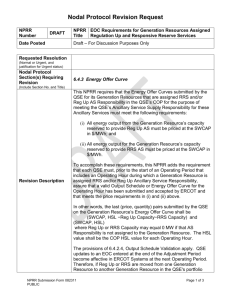

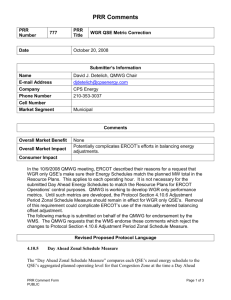

advertisement

Developing a Quality Management System Viki Massey Quality Coordinator A Joint Venture of London Health Sciences Centre and St. Joseph’s Health Care London Today’s Presentation LLSG profile Implementation Plan Outline Quality System Essentials Review: Where are we? Outline the next steps London Laboratory Services Group Joint venture between LHSC and SJHC Pathology and Laboratory Medicine Program 9 disciplines 55 laboratories 4 campuses 500 employees What is a Quality Management System ISO 9000 defines a QMS as: “ Management system to direct and control an organization with regard to quality” Why Quality Management System? QMP-LS: Quality Management Program – Laboratory Services; Ontario Laboratory Accreditation (OLA) Consistent with international trends and laboratory science We are committed to providing the highest level of care to the patient How to Implement a Quality Management System? LLSG Implementation Plan Quality Coordinator Discipline Task Teams Quality Team Develop Policies GAP analysis Map Processes Write procedures Quality Manual Communicate/Educate/Train Audit Accreditation Structure for a Quality system Quality System Essentials Organization Personnel Path of Workflow Pre-Analytic Analytic Post-Analytic Info Mgmt Equipment Purchasing/Inventory Process Control Documents/Records Occurrence Mgmt Internal Assessment Process Improvement Service and Satisfaction Facilities and Safety Information Management Quality system essentials apply to all operations in the path of workflow QSE: Documents and Records Document - - - create identify change approve file distribute archive Management System Hierarchy of Documents Policy Process Procedures Forms What to do How it happens How to do it Records Policy Development Quality Policies - QSE’s Map OLA requirements Policy statement Responsibility Supporting statements Supporting processes - included in procedures - - Operational Policies POLICY STATEMENT: PURPOSE: This policy provides the direction for the processes and procedures to…. RESPONSIBILITY (use those that apply) Program Leader/Discipline Leader/Section Head is responsible for Lab Manager is responsible for Technical Specialist/Coordinator is responsible for Staff members are responsible for Other: The following sections are derived from the OLA requirements. They determine the supporting statements for the policy. There should be one section and related statement for the major categories defined in the requirements. Make a broad statement about the Laboratory's intentions for the sections below. SECTION SUPPORTING STATEMENTS References: NCCLS document HS1-A Vol.22, No.13- A Quality System Model for Health Care; Approved Guideline QMP-LS- Ontario Laboratory Accreditation Requirements Others: Supporting Documents List the processes that support this policy: Process Mapping Address the path of workflow Describe how things happen here Flow Charts or Tables What Happens (List the steps) 1) 2) 3) Who’s responsible Procedure (or another Process) Results Procedure Development Identified from process mapping Templates developed based on NCCLS guidelines Used for analytical and non analytical procedures PURPOSE POLICY EQUIPMENT MATERIALS SPECIMEN SPECIAL SAFETY QUALITY CONTROL PROCEDURE LIMITATIONS INTERPRETATION CALCULATIONS REFERENCE RANGE RESULTS REPORTING REFERENCES RELATED DOCUMENTS APPENDICES This procedure gives instructions…… Procedures Accessible Up to date User friendly- accurate, easy to follow QSE: Process Control Laboratory processes and procedures Validation Establishing Reference Intervals Quality Control Internal and External QA Method Comparability Accreditation QSE: Occurrence Management Quality Control: Corrective Action External and Internal Quality Assurance Turn Around Time (TAT) delay Discrepant Results Corrected Results Specimen Rejection Criteria QSE: Information Management Results Reporting Release of Results Computer Procedures Change Approval Computer QA Computer Security Computer Validation QSE: Purchasing and Inventory Inventory Control System External Services Purchasing Documents Material Resources QSE: Safety Safety Officer, Safety Committee Safety Manual Audit and Inspections Reporting Incidents, Accidents, Illness Training Personnel Responsibilities QSE: Facilities Location and design Environmental Conditions Access Communication Systems Storage Computer Environment QSE: Equipment Equipment selection, calibration, verification, validation Inventory Equipment operation maintenance and records Defective Equipment QSE: Personnel Job Description and Qualifications Training Competence Continuing Education Personnel Records Performance Appraisal QSE: Organization License Mission Statement Accreditation Organizational Structure Resource Allocation Referral Laboratories QSE: Assessment Quality Indicators Internal Audits Management Review QSE: Process Improvement Quality Improvement Activities Occurrence management Problem Solving QSE: Service and Satisfaction Customer Satisfaction (Complaints) Internal and external Where are We? Quality Team Quality policies developed Processes identified/mapped Procedures written Document Management System Quality Manual Web site for referral labs Where are We? Discipline Task Teams GAP analysis Processes mapped Procedures written Revisit requirements and close GAP What’s Next? Quality Team to continue to address QSE Discipline Task Teams to complete sections of OLA requirements Educate and train staff Perform self assessment Celebrate Success! Resource Material • • • • • ISO documents: 9001:2000 15189 NCCLS documents: GP26-A GP22-A HS1- A QMP-LS- OLA Consensus Requirements