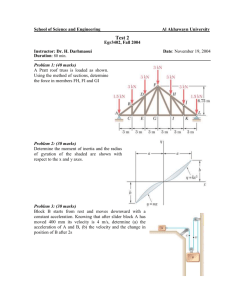

Document

advertisement

Machine Dynamics-I (ME-404) Instructor: Dr. Subrata Kumar Panda, PhD Area of Expertise: Solid Mechanics, Nonlinear Vibration Smart Composite Structures Laminated Composite Shell Structure Nonlinear FEM Modeling and Simulation Shape Memory Alloy Contact details:call2subrat@gmail.com * Mob: 9658583368 * Mail contact will be appreciated Mechanics Theoretical Mechanics Micro/Nano Mechanics Solid Computational Mechanics Continuum Mechanics Fluid Applied Mechanics System Multiphysics Computational Mechanist: Person having problem (engg. problem/ design complex prob.) searching for the solution Applied Mechanist: Person having solution searching for the problem Theoretical Mechanist: Person who will show the existence of solution and the problem Courses of Studies 1. Simple Mechanism: Classification of links and pairs, kinematics chains, degrees of freedom, Grashof’s law, Kutzbach criterion, Grubler’s criterion for plane mechanism. Four bar mechanism and its inversions. Single slider crank chain and its inversions. Double slider crank chain and its inversion. 2. Velocity in Mechanism: Velocity of a point on a link by instantaneous center method, Numbers and types of instantaneous centers in a mechanism. Location of instaneaous centers. Kennedy’s theorem, Velocity of a point in a link by relative velocity methods. Velocities of four-bar and slider crank mechanism. 3. Acceleration in Mechanism: Acceleration of point on a link, Acceleration diagram of a link, Acceleration in the slider crank and four bar mechanism .Klein’s construction, Analytical method of finding acceleration of a piston and connecting rod, Coriolis’ components of acceleration. 4. Kinetics: Equivalent dynamical system to replace a rigid body, two mass systems, Hook’s joint, Davis and Ackerman Steering gears. Compound pendulum, Bifilar and Trifler suspension 5. Friction: Friction of a square threaded screw and V-threads, Friction of journal, pivot and collar bearings, single plate, multiplate and conical clutches (Centrifugal clutch). 6. Belt and Rope Drive: Velocity ratio, Effect of belt thickness and slip on velocity ratio, Length of belt, Ratio of driving tensions, Power transmitted by belt ,Centrifugal tension .Maximum power transmitted by belts, Creep and initial tension, V-belt. Ratio of tensions in rope drive. 7. Brakes and Dynamometer: Block brakes, Band Brakes, Band and Block Brakes, Absorption and Transmission Dynamometers, Pony Brakes, Rope Brake, Belt Transmission and torsional Dynamometer. 8. Kinematics of Cam: Types of cams and followers, Displacement velocity and acceleration-time curves for uniform velocity, uniform acceleration, simple harmonic motion and cycloid motion, Graphical construction of cam profiles for different types of followers, Cams with specified contours. Text Book: 1. Theory of Machines by S. S. Ratan, TMH Reference Book: 1. Theory of Machines by Shigley J, TMH 2. Machines and Mechanisms: Applied Kinematics Analysis by David H Myszka, PHI 3. Theory of Mechanism and machines by Sharma & Purohit, PHI 4. Theory of Machines by Thomas Bevan 5. Some more references •NPTEL Lecture Notes •Carnegie Mellon University Lecture Notes •MIT Lecture Notes •Springer Lecture Notes on Dynamic System Module No.&Name Section No.&Name Lesson Plan Topics/Coverage No of Lectures Lecture Serial Nos. 1.Introduction Topics to be covered, their objectives and real world engineering applications. 1 1-1 2. Frictions(Part-I) 1.Friction of a square threaded screw and V-threads 4 2-5 3. Simple Mechanism 1.Classification of links and pairs 2. Four-bar, slider crank and Double slider crank mechanism and their inversions, mobility simple mechanism 3.Problems 6 6-11 4.Velocity Analysis of Mechanism 1.Instantaneous center, Kenndy’s theorems, 5 2.Relative velocity methods 3. Velocity diagram of four-bar and slider crank mechanisms. 4.Problems 12-16 5. Frictions(Part-II) 1Journal, pivot and collar bearings 2.Plate clutch and conical clutch 3 Problems 17-21 5 L.P. Contd. 6.Brakes and Dynamometer 7.Acceleration Analysis of Mechanism 8.Lower Pairs 9.Belt and Rope Drives 1.Block and Band Brakes 2.Absorption and Transmission Dynamometers 3.Problems 1.Accelerations of four-bar , slider crank mechanisms and acceleration diagram 2. Klein’s construction and Coriolis’ components of acceleration. 3.Problems 4 22-25 4 26-29 1. Steering Mechanism and Ackermann Steering Mechanism 2.Hooke’s Joint: Single and Double 3.Problems 1.Open and Cross belts their length and velocity ratio 2. Ratio of driving tensions, power transmitted by belt and centrifugal tension 3.Slip and creep in belt and initial tension 4.V-belt and ratio of tensions in rope drive 5..Problems 5 30-34 6 35-40 6 41-46 10.Kinematics of 1.Types of cams and followers 2. Displacement, velocity and acceleration –time curves. 3.Graphical construction of cam profiles 4. Problems Machine Dynamics Kinematics and Dynamics of Machines Kinetics and Kinematics of Machines Theory of Machines Mechanism: the fundamental physical or chemical processes involved in or responsible for an action, reaction or other natural phenomenon. Machine: an assemblage of parts that transmit forces, motion and energy in a predetermined manner. Simple Machine: any of various elementary mechanisms having the elements of which all machines are composed. Included in this category are the lever, wheel and axle, pulley, inclined plane, wedge and the screw. The word mechanism has many meanings. In kinematics, a mechanism is a means of transmitting, controlling, or constraining relative movement. Movements which are electrically, magnetically, pneumatically operated are excluded from the concept of mechanism. The central theme for mechanisms is rigid bodies connected together by joints. A machine is a combination of rigid or resistant bodies, formed and connected do that they move with definite relative motions and transmit force from the source of power to the resistance to be overcome. A machine has two functions: transmitting definite relative motion and transmitting force. These functions require strength and rigidity to transmit the forces. The term mechanism is applied to the combination of geometrical bodies which constitute a machine or part of a machine. A mechanism may therefore be defined as a combination of rigid or resistant bodies, formed and connected so that they move with definite relative motions with respect to one another. Although a truly rigid body does not exist, many engineering components are rigid because their deformations and distortions are negligible in comparison with their relative movements. The similarity between machines and mechanisms is that •they are both combinations of rigid bodies •the relative motion among the rigid bodies are definite. The difference between machine and mechanism is that machines transform energy to do work, while mechanisms so not necessarily perform this function. The term machinery generally means machines and mechanisms. The following figure shows a picture of the main part of a diesel engine. The mechanism of its cylinder-link-crank parts is a slider-crank mechanism, as shown in Cross section of a power cylinder in a diesel engine Skeleton outline