Introduction to workshop safety

advertisement

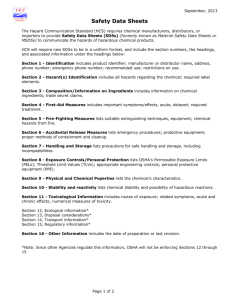

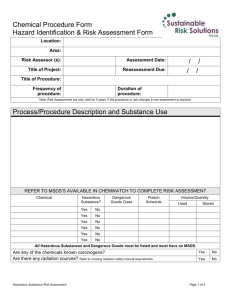

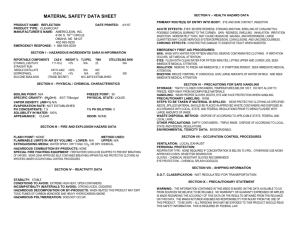

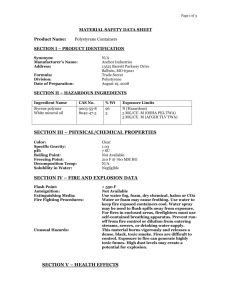

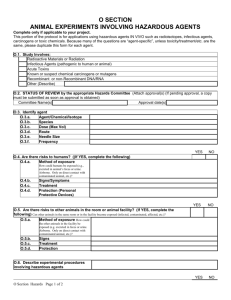

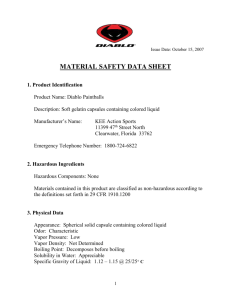

Introduction to Workshop Safety This presentation will explore: Safety Clothing Workshop Safety Hazards Safety Data Sheets and Labels Storage and Spills Introduction to Workshop Safety Typical Workshop Safety Hazards A number of accidents could occur in a vehicle workshop: Fires and explosions. Asphyxiation. Chemical burns. Electric shocks. Physical injuries. Important to know what action to take and how to minimize accidents. Next > Introduction to Workshop Safety Question 1 Which of the following is a possible cause of accidents? A) Slippery floor B) Chemical burns C) Physical injury D) Asphyxiation Introduction to Workshop Safety Basic Personal Protective Clothing Personal protective clothing helps minimize personal injury in the event of an accident. Basic protective clothing is: Overalls. Protective boots. Latex gloves. If not overalls, clothing must be well fitting and of hardwearing material. Next > Introduction to Workshop Safety Eye Protection Eye damage can result from small particles, sharp objects, liquids, gases or intense light. Typical eye protection is: Safety glasses. Safety (splash) goggles. Face shield. Welding helmet (mask). Hazardous liquids in eyes must be washed out with clean water or eye wash. Next > Introduction to Workshop Safety Question 2 Eyes can be damaged by intense light. Is this true or false? Answer True or False. Introduction to Workshop Safety Hand Protection Hands may be injured in a workshop by cuts, skin damage or chemical burns. Gloves worn to help prevent injuries: Latex gloves. Rubber gloves. Leather gloves. Next > Introduction to Workshop Safety Ear and Respiratory Protection Loud noises over long periods can damage ears. Ear defenders and earplugs can protect ears. Respiratory equipment required during some tasks, or breathing difficulties, headaches, dizziness or sickness may occur. Dust masks and respirators are used. Next > Introduction to Workshop Safety Question 3 Ears will not be damaged by loud noises as long as they are low frequency noises. Is this true or false? Answer True or False. Introduction to Workshop Safety Lifting and Carrying Bulky objects must be lifted and carried correctly to prevent injury (particularly to the back). Ensure feet are close to object keeping back straight. Keep object as close to body as possible when lifting. Lift from leg muscles, back must be straight all the time. Next > Introduction to Workshop Safety Question 4 Which part of the body is MOST at risk from lifting objects that are too heavy? A) The feet B) The legs C) The knees D) The back Introduction to Workshop Safety First Aid Seek medical help after an accident. First aid station and first aid representative available. First aid station has minor injury relief and eye wash. First aid representative provides basic assistance. Call professional services for more serious accidents. Next > Introduction to Workshop Safety Workshop Ventilation and Lighting Workshop must be ventilated to remove fumes. Fans and exhaust extraction used. Good lighting essential to see work. Portable lamps direct light to work areas. Next > Introduction to Workshop Safety Question 5 Why should workshops be ventilated? A) To prevent chemical burns B) To remove moisture C) To remove any fumes D) To provide a constant working temperature Introduction to Workshop Safety Fire Extinguishers Location and type of extinguishers must be known. Different classes of fire extinguisher: Class A Class B Class C Class D Class E Class F Typical fire extinguisher types: Water Foam Dry powder/chemical Carbon dioxide (CO2) Halon - Illegal in the UK after Dec 2003 Next > Introduction to Workshop Safety Question 6 How many different classes of fire extinguishers are there? Enter your answer and press SEND. Introduction to Workshop Safety Fire Exits and Assembly Points Use designated fire exits to evacuate building and meet at assembly point. Fire notices provide information. Next > Introduction to Workshop Safety Hazardous Materials Hazardous materials found in workshop. Take precautions when handling. Typical hazardous materials: Fuel. Battery acid (electrolyte). Engine oil. A/C refrigerant. Engine coolant (antifreeze). Brake, transmission and power steering fluid. Cleaning chemicals. Paints and thinners. Brake and clutch dust. Next > Introduction to Workshop Safety Question 7 For which of the following hazardous materials would it NOT be necessary to wear respiratory protection? A) Engine oil B) Fuel C) Battery acid D) Brake and clutch dust Introduction to Workshop Safety Health and Safety Standards HSE govern handling of hazardous materials within COSHH. Help prevent exposure to health hazards. Employers and employees must comply to certain standards. Supervision of a task may be necessary. Next > Introduction to Workshop Safety Material Safety Data Sheets MSDS provides information about hazardous products. Available in workshop. MSDS information includes: What the product is. Manufacturer details. Product ingredients. Physical description. Potential health hazards. Conditions that could increase hazard. How to safely handle it. What to do if exposed to it. What to do in the event of a spill. Next > Introduction to Workshop Safety Question 8 What do the initials MSDS stand for? A) Manufacturers Safety Data Sheets B) Material Safety Data Sheets C) Manufacturers Standard Data Sheets D) Material Safety Definition Sheets Introduction to Workshop Safety Product Warning Labels Hazardous materials container/ packaging has product warning label including: What the product is. Manufacturer details. Hazard types. Potential health hazards. Protection. Warning symbols indicate type of hazard associated with a material/chemical. Next > Introduction to Workshop Safety Hazardous Material Health Symptoms Hazardous material contact can cause physical symptoms: Breathing difficulties. Irritation of the nose, throat or lungs. Discomfort/headaches. Fatigue/weakness. Dizziness. Loss of consciousness. Restricted movement. Poor/blurred vision. Seek medical attention immediately if symptoms occur. Next > Introduction to Workshop Safety Question 9 An employee has been working in the workshop for a while when they stop work and sit down complaining of blurred vision and a feeling of dizziness. What is the first action to take? A) Check the product warning labels for any chemicals they have been using B) Check the MSDS for any chemicals they have been using C) Check to see if any other employees are exhibiting the same symptoms D) Seek medical attention immediately Introduction to Workshop Safety Hazardous Material Storage Check COSHH, product label and MSDS. Use approved storage containers, and seal and label properly. Check containers regularly. Next > Introduction to Workshop Safety Question 10 A tin of liquid without its label is found in the workshop. What should be done with it? A) It should be disposed of safely B) Find out what it is and store it with other tins of the same liquid C) Transfer it into another tin bearing the correct label D) Make a temporary label for it until someone can identify it Introduction to Workshop Safety Dealing With Spillages Fuel leaks, oil leaks, damaged/ dropped containers etc. Clean up immediately, wear appropriate clothing and do not let into drain. Use appropriate clean-up material and dispose of properly. Next > Introduction to Workshop Safety Disposal of Workshop Waste Used engine/transmission oils, coolant, fluids, used oil filters, rags and used cleaning chemical. Properly store in sealed and labelled containers. Some waste can be recycled, e.g. recovered A/C refrigerant. Other waste must be disposed of following strict regulations. Next > Introduction to Workshop Safety Summary You should now be aware of: Safety Clothing Workshop Safety Hazards Safety Data Sheets and Labels Storage and Spills End >