Monitoring Well Post-Installation Consideration

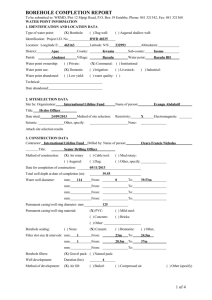

advertisement

Monitoring Well Post-Installation Consideration By: Pierre-Orly Dupont Introduction ► Post-Installation for: Considerations is important Well’s and system’s integrity. Well’s Identity. Long-term operation. Well Post-Installation considerations include: ► Monitoring well development. ► Reporting of construction details. ► Maintenance and rehabilitation. ► Abandonment (decommission). Well Development General Considerations Methods AirLift Surging and Pumping with Compressed Air Mechanical Surging Work for most monitoring well Variety of depth-towater conditions Surface Centrifugal Pump Submersible Pump Surge Block Bailer High-Pressure Water Jetting Decontamination Surveying General Considerations ► During installation: There can be a loss of drilling fluids when encountering high permeable materials. This loss must be recovered. Fine materials from adjacent formation must be removed as they can alter the permeability of filter-packed monitoring wells. Extraneous materials may be dropped into the well. Cuttings may stick to the borehole wall above water table (air-rotary drilling). Cuttings from silt or clay can smear the borehole wall (hollow stem auger). General Considerations ► Goals of monitoring well development: Remove fine materials (silt, clay, fine sand). Remove water lost during drilling. Correct damage to the borehole wall. Stabilize the filter pack and formation Maximize the hydraulic communication between the well and the adjacent formation material. Installation of a monitoring well should not be considered complete until it has been properly developed. In other words, developing a well involves procedures used to maximize its yield by attempting to restore the geologic formation to a predrilling state. Well development activity ► The application of sufficient energy to create ground-water flow reversals (surging). ► Pumping to draw water lost to the formation during drilling out of the borehole and adjacent formation, along with the fines that have been brought into the well during surging. Monitoring well development should continue until: ► Visibly clear water is discharged during the active (surging) portion of the development process. ► Field-measured quality (e.g., pH, Eh, conductivity) of the discharged water stabilizes and the turbidity is reduced to less than 10 Nephelometric Turbidity Units (NTU). ► The total volume of water discharged from the well is at least equal to the estimated volume of fluid lost to the formation during drilling and well installation. ► Therefore, there are methods to accomplish this development. Well Development General Considerations Methods AirLift Surging and Pumping with Compressed Air Mechanical Surging Work for most monitoring well Variety of depth-towater conditions Surface Centrifugal Pump Submersible Pump Surge Block Bailer High-Pressure Water Jetting Decontamination Surveying Airlift Surging and Pumping with Compressed Air ► Work for most monitoring wells. ► Should use a dual-line airlift system instead of conventional single-line airlift. Introduction of oil. Change in water chemistry. May reduce hydraulic conductivity of formation. Difficult to control Airlift Surging and Pumping with Compressed Air ► Work for most monitoring wells. ► Should use a dual-line airlift system instead of conventional single-line airlift. Introduction of oil. Change in water chemistry. May reduce hydraulic conductivity of formation. Difficult to control. ► Must be at least 20%-40% of submergence of the air discharge line. Determine submergence % pumping submergence = Length of air line below pumping water level Total length of air line X 100 = (195/395) X 100 = 50% Well Development General Considerations Methods AirLift Surging and Pumping with Compressed Air Mechanical Surging Work for most monitoring well Variety of depth-towater conditions Surface Centrifugal Pump Submersible Pump Surge Block Bailer High-Pressure Water Jetting Decontamination Surveying Mechanical Surging ► To force water to flow into and out of a screen by operating a plunger up and down in the casing. Well Development General Considerations Methods AirLift Surging and Pumping with Compressed Air Mechanical Surging Work for most monitoring well Variety of depth-towater conditions Surface Centrifugal Pump Submersible Pump Surge Block Bailer High-Pressure Water Jetting Decontamination Surveying Mechanical Surging using For shallow well. For wide variety of depth. Surface Centrifugal Pump Submersible Pump ► Can be performed only if the depth to water is within the practical limit of suction lift. Less than 20 feet below ground surface. Pump must be decontaminated. ► New, unused discharge line from the pump should be used. ► No touching ground to avoid contamination. ► Not limited by suction lift. ► Mechanical Surging with Surge Block ► ► ► ► ► Swab. Raising and lowering a surge block heavy enough to free-fall through the water. Dependent on the length and force of the surging strokes. For deeper well, should use mechanical assistance. Involves only surging. Bailer Useful for wells in low-yield formations. ► Bailer needs to clean. ► Labor-intensive. ► Require more time than other methods. ► Well Development General Considerations Methods AirLift Surging and Pumping with Compressed Air Mechanical Surging Work for most monitoring well Variety of depth-towater conditions Surface Centrifugal Pump Submersible Pump Surge Block Bailer High-Pressure Water Jetting Decontamination Surveying High-Pressure Water Jetting ► ► ► ► ► Required equipment is large. Not man-portable. May be done by water or air. Use centrifugal pumps or submersible pumps. Help correct damage to the formation’s porosity and permeability. Well Development General Considerations Methods AirLift Surging and Pumping with Compressed Air Mechanical Surging Work for most monitoring well Variety of depth-towater conditions Surface Centrifugal Pump Submersible Pump Surge Block Bailer High-Pressure Water Jetting Decontamination Surveying Well Development General Considerations Methods AirLift Surging and Pumping with Compressed Air Mechanical Surging Work for most monitoring well Variety of depth-towater conditions Surface Centrifugal Pump Submersible Pump Surge Block Bailer High-Pressure Water Jetting Decontamination Surveying Surveying ► Locations of monitoring wells may be plotted onto maps for developing and interpreting hydrologic data. ► Water-level measurements. ► Ground water contour map. ► Elevations (National Geodetic Vertical Datum) ► GPS. ► Well Identification: Placing a number on protective case. Well Post-Installation considerations include: ► Monitoring well development. ► Reporting of construction details. ► Maintenance and rehabilitation. ► Abandonment (decommission). Reporting of construction details. ► Results of monitoring can be affected by the details of the well’s construction. ► Presented in full detail as an appendix to a report. ► Report include: (page 866-817) Borehole diameter. Length of screen. Ground surface elevation…. Well Post-Installation considerations include: ► Monitoring well development. ► Reporting of construction details. ► Maintenance and rehabilitation. ► Abandonment (decommission). Monitoring Well Maintenance and Rehabilitation ► Maintenance program: (page 870) Surface Observations Subsurface Observations Ground-water sample quality (wait for lab result) ► Rehabilitation program: Well performance has been reduced. Ground-water sample quality has changed. Well Post-Installation considerations include: ► Monitoring well development. ► Reporting of construction details. ► Maintenance and rehabilitation. ► Abandonment (decommission). Monitoring Well and Borehole Decommissioning. (abandonment) ► One of most important post-construction of a ground-water monitoring program. ► 2 main objectives to decommissioning: Restore the borehole to its original condition. Prevent cross-contamination between formation. ► Should be planned and well document just like original well. Planning for Decommissioning ►6 key element: State, federal or local regulations (Table 12.3) Planning for Decommissioning ►6 key element: State, federal or local regulations (Table 12.3) Type of well or borehole to be decommissioning. Hydrogeologic environment. Chemical environment. Disposal of potential contamination. Type of equipment and quantity of grouting needed. Decommissioning Material ► ► ► ► TYPE I Portland Cement. Sodium bentonite. Use of granular, chip, or pellet forms of bentonite (when little water is present) Use a tremie pipe to place those materials Procedures for Decommissioning ► Recheck planning of decommissioning. ► Be sure well is free of debris. ► Determine depth of well. ► Fill the length of the screen with fine sand. ► Place decommissioning material. ► Make records and reports. FIN Any questions?