display

advertisement

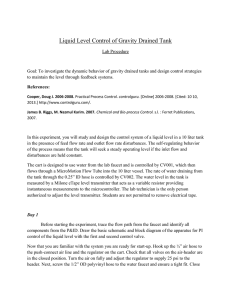

P13631: Gravity Fed Flow Process Control Teaching Aid Introduction Cart Layout Theory Draining a tank is a non-integrating (or selfregulating) process. A constant liquid level corresponds with an inlet flow set to match the outlet flow via the control valves on the cart. This is conveyed through equations below: An RIT education couples theory in lecture with practical application in lab. In the past, carts have been built by senior design groups to demonstrate lecture concepts. This project combines the dynamics of a gravity drained tank with LabVIEW to teach process control. The team progressed from theoretical design and planning to implementation over the course of 7 months. The final result is a functioning cart to teach process control. Project details can be found at our website: http://edge.rit.edu/edge/P13631/public/Home Gc = controller transfer function Kc = controller gain from tuning KaKp = Kc; the actuator and process gains Τc = controller time constant Τv = valve time constant S = transfer function variable in the Laplace transform space τI = integration time constant Kp = process time constant Customer Needs • • • • • • • Safety and ergonomics Student learning Transportability Ease of maintenance Minimal water use Minimal cost Interface with LabVIEW Combining all process dynamics yields: Design Process Cart Features Y(s) = output of process Ys(s) = set point of process Gd = derivative transfer function D(s) = disturbance output Gc = controller transfer function Ga = valve transfer function Gp = process transfer function Gs = level or flow transmitter transfer function. • Leaf table to increase student workspace • Aluminum bracketing to decrease weight and increase mobility • Wheels and brakes to increase mobility and practicality Testing Results Safety Testing Result Functionality Testing Center of gravity Pass Stress and deflection Pass Process constants Gain (inches/percent open) Time constant (min) Electricity grounding Pass Control Valve 1 0.9 15.37 Control Valve 2 1.6 7.45 Conclusions and Recommendations The final cart meets customer needs and can be used by students to safely learn about process control. Improvements for the future include: Reducing water use • Install a pump to reroute water to supply instead of drain. • Install an additional holding tank for water with a recirculation pump. The group chose the line pressure cart that used a sink faucet to supply water at approximately 45 psi. Based on the Pugh chart and risk analysis, that design had the fewest number of risks. Testing time to complete lab procedure • Conduct a time trial with 4th year Chemical Engineering students and the lab manual to confirm each day takes three hours to complete. Team Members (left to right): • • • • • • Lead Engineer: James Brinkerhoff, ChE Project Manager: Christopher Kulbago, ChE Fluids Specialist: Lauren Pahls, ChE Team Facilitator: Sarah Salmon, ChE Electrical Lead: Ted Rakiewicz, EE Mechanical Lead: Patrick O’Connell, ME This project was made possible by our faculty guide, Steve Possanza, our customer, Dr. Richter, our process controls professor, Dr. Sanchez, and the Chemical Engineering Department Lab Technician, Paul Gregorius.