CAPACITY

advertisement

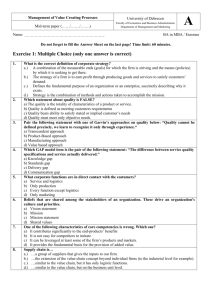

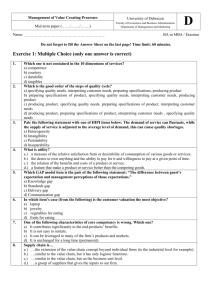

Capacity Planning Capacity Capacity (A): is the upper limit on the load that an operating unit can handle. Capacity (B): the upper limit of the quantity of a product (or product group) that an operating unit can produce (= the maximum level of output) Capacity (C): the amount of resource inputs available relative to output requirements at a particular time The basic questions in capacity handling are: What kind of capacity is needed? How much is needed? When is it needed? How does productivity relate to capacity? Importance of Capacity Decisions 1. 2. 3. 4. 5. 6. 7. Impacts ability to meet future demands Affects operating costs Major determinant of initial costs Involves long-term commitment Affects competitiveness Affects ease of management Impacts long range planning Examples of Capacity Measures Type of Organization Manufacturer Hospital Airline Restaurant Retailer Theater Measures of Capacity Inputs Outputs Machine hours Number of units per shift per shift Number of beds Number of patients treated Number of planes Number of or seats seat-miles flown Number of seats Customers/time Area of store Sales dollars Number of seats Customers/time Capacity Designed capacity maximum output rate or service capacity an operation, process, or facility is designed for = maximum obtainable output = best operating level Effective capacity Design capacity minus allowances such as personal time, maintenance, and scrap Actual output = Capacity used rate of output actually achieved. It cannot exceed effective capacity. Capacity Efficiency and Capacity Utilization Actual output Efficiency = Effective capacity Actual output Utilization = Design capacity Numeric Example Design capacity = 10 tons/week Effective capacity = 8 tons/week Actual output = 6 tons/week Efficiency Utilization Actual output = = Effective capacity Actual output Design capacity 6 tons/week = = 8 tons/week 6 tons/week 10 tons/week = 75% = 60% Determinants of Effective Capacity Facilities Product and service factors Process factors Human factors Operational factors Supply chain factors External factors Key Decisions of Capacity Planning 1. 2. 3. 4. Amount of capacity needed Timing of changes Need to maintain balance Extent of flexibility of facilities Capacity Cushion level of capacity in excess of the average utilization rate or level of capacity in excess of the expected demand. extra demand intended to offset uncertainty Cushion = (designed capacity / capacity used) - 1 High cushion is needed: service industries high level of uncertainty in demand (in terms of both volume and product-mix) to permit allowances for vacations, holidays, supply of materials delays, equipment breakdowns, etc. if subcontracting, overtime, or the cost of missed demand is very high Steps for Capacity Planning 1. 2. 3. 4. 5. 6. 7. 8. Estimate future capacity requirements Evaluate existing capacity Identify alternatives Conduct financial analysis Assess key qualitative issues Select one alternative Implement alternative chosen Monitor results (feedback) Sources of Uncertainty Manufacturing Customer delivery Supplier performance Changes in demand The „Make or Buy” problem 1. 2. 3. 4. 5. 6. Available capacity Expertise Quality considerations Nature of demand Cost Risk Developing Capacity Alternatives 1. 2. 3. 4. 5. 6. Design flexibility into systems Take stage of life cycle into account (complementary product) Take a “big picture” approach to capacity changes Prepare to deal with capacity “chunks” Attempt to smooth out capacity requirements Identify the optimal operating level Economies of Scale Economies of scale If the output rate is less than the optimal level, increasing output rate results in decreasing average unit costs Diseconomies of scale If the output rate is more than the optimal level, increasing the output rate results in increasing average unit costs Evaluating Alternatives Average cost per unit Production units have an optimal rate of output for minimal cost. Minimum average cost per unit Minimum cost 0 Rate of output Evaluating Alternatives II. Average cost per unit Minimum cost & optimal operating rate are functions of size of production unit. Small plant Medium plant 0 Output rate Large plant Planning Service Capacity Need to be near customers Inability to store services Capacity and location are closely tied Capacity must be matched with timing of demand Degree of volatility of demand Peak demand periods Some examples of demand / capacity Adapting capacity to demand through changes in workforce DEMAND PRODUCTION RATE (CAPACITY) Adaptation with inventory DEMAND Inventory accumulation CAPACITY Inventory reduction Adaptation with subcontracting DEMAND SUBCONTRACTING PRODUCTION (CAPACITY) Adaptation with complementary product DEMAND DEMAND PRODUCTION (CAPACITY) PRODUCTION (CAPACITY) Seminar exercises Homogeneous Machine Designed capacity in calendar time CD= N ∙ sn ∙ sh ∙ mn ∙ 60 (mins / planning period) CD= designed capacity (mins / planning period) N = number of calendar days in the planning period (≈ 250 wdays/yr) sn= maximum number of shifts in a day (= 3 if dayshift + swing shift + nightshift) sh= number of hours in a shift (in a 3 shifts system, it is 8) mn= number of homogenous machine groups Designed capacity in working minutes (machine minutes), with given work schedule CD= N ∙ sn ∙ sh ∙ mn ∙ 60 (mins / planning period) CD= designed capacity (mins / planning period) N = number of working days in the planning period (≈ 250 wdays/yr) sn= number of shifts in a day (= 3 if dayshift + swing shift + nightshift) sh= number of hours in a shift (in a 3 shifts system, it is 8) mn= number of homogenous machine groups Effective capacity in working minutes CE = CD - tallowances (mins / planning period) CD= designed capacity tallowances = allowances such as personal time, maintenance, and scrap (mins / planning period) The resources we can count with in product mix decisions b = ∙ CE b = expected capacity CE = effective capacity = performance Produktumok Product types T1 percentage T i Tn Resources Erőforrások E1 E2 a11 a21 a1i a2i a1n a2n Ei a a a Em am1 i1 i i am i erőforrás Resource utilization felhasználási coefficients koeficiensek i n amn Erőforrások Expected nagysága (kapacitás) Capacities óra/időszak b1 b2 bi bm Exercise 1.1 Set up the product-resource matrix using the following data! RU coefficients: a11: 10, a22: 20, a23: 30, a34: 10 The planning period is 4 weeks (there are no holidays in it, and no work on weekends) Work schedule: E1 and E2: 2 shifts, each is 8 hour long E3: 3 shifts Homogenous machines: 1 for E1 2 for E2 1 for E3 Maintenance time: only for E3: 5 hrs/week Performance rate: 90% for E1 and E3 80% for E2 Solution (bi) Ei = N ∙ sn ∙ sh ∙ mn ∙ 60 ∙ N=(number of weeks) ∙ (working days per week) E1 = 4 weeks ∙ 5 working days ∙ 2 shifts ∙ 8 hours per shift ∙ 60 minutes per hour ∙ 1 homogenous machine ∙ 0,9 performance = = 4 ∙ 5 ∙ 2 ∙ 8 ∙ 60 ∙ 1 ∙ 0,9 = 17 280 minutes per planning period E2 = 4 ∙ 5 ∙ 2 ∙ 8 ∙ 60 ∙ 2 ∙ 0,8 = 38 720 mins E3 = (4 ∙ 5 ∙ 3 ∙ 8 ∙ 60 ∙ 1 ∙ 0,9) – (5 hrs per week maintenance ∙ 60 minutes per hour ∙ 4 weeks) = 25 920 – 1200 = 24 720 mins Solution (RP matrix) T1 E1 E2 E3 T2 T3 T4 10 b (mins/y) 17 280 20 30 30 720 10 24 720 Exercise 1.2 Complete the corporate system matrix with the following marketing data: There are long term contract to produce at least: Forecasts says the upper limit of the market is: 50 T1 100 T2 120 T3 50 T4 10 000 units for T1 1 500 for T2 1 000 for T3 3 000 for T4 Unit prices: T1=100, T2=200, T3=330, T4=100 Variable costs: E1=5/min, E2=8/min, E3=11/min Solution (CS matrix) T1 E1 T2 T3 T4 10 17 280 20 E2 b (mins/y) 30 30 720 10 E3 MIN (pcs/y) 50 100 120 50 MAX (pcs/y) 10 000 1 500 1 000 3 000 p 100 200 330 100 f 50 40 90 -10 24 720 What is the optimal product mix to maximize revenues? T1= 17 280 / 10 = 1728 < 10 000 T2: 200/20=10 T3: 330/30=11 T4=24 720/10=2472<3000 T2= 100 T3= (30 720-100∙20-120∙30)/30= 837<MAX What if we want to maximize profit? The only difference is in T4 because of its negative contribution margin. T4=50 Exercise 2 T1 E1 T2 T3 T4 T5 T6 6 b (hrs/y) 2 000 3 E2 2 3 000 4 E3 1 000 6 1 E4 E5 3 4 MIN (pcs/y) 0 200 100 250 400 100 MAX (pcs/y) 20000 500 400 1000 2000 200 p (HUF/pcs) 200 100 400 100 50 100 f (HUF/pcs) 50 80 40 30 20 -10 6 000 5 000 Solution Revenue max. T1=333 T2=500 T3=400 T4=250 T5=900 T6=200 Contribution max. T1=333 T2=500 T3=400 T4=250 T5=966 T6=100