CHAPTER 4 MARLINSPIKE SEAMANSHIP

advertisement

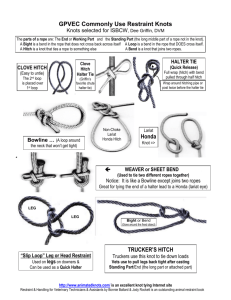

SEAMANSHIP CH. 4 MARLINSPIKE SEAMANSHIP MARLINSPIKE 1. Again, the reference text for this chapter is CHAPMAN, PILOTING AND SEAMANSHIP, Marlinspike 2. AUXSEA STUDENT STUDY GUIDE 3 BASIC TYPES OF ROPE(LINE) 1. Natural 2. Synthetic 3. Wire NATURAL ROPE(Line) MANILA and COTTON 1. About the only two kinds of natural rope(line) left. 2. LINE: Name given to all ropes when put to use aboard a vessel. 3. Two or three strands TWISTED clockwise to form one single strand. NATURAL ROPE(LINE) MANILA 1. Made from plant fibers. 2. Most popular ADVANTAGES 1. Readily available 2. Inexpensive 3. Very durable MANILA DISADVANTAGES 1. Manila deteriorates if stowed wet, damp or left in the bright sunlight. NOTE Manila has been virtually replaced by synthetic lines especially for running rigging COTTON LINE ADVANTAGES 1. Pliable 2. Runs smoothly in blocks DISADVANTAGES 1. ½ Strength of Manila 2. Susceptible to rot 3. Stretches, especially when wet WORKING TOOL(S) FID and MARLINSPIKE 1. A FID is the instrument or tool used to work on natural and synthetic lines and is usually made of WOOD, PLASTIC or ALUMINUM, SO AS NOT TO DAMAGE THE LINE while working it. 2. MARLINSPIKE: In appearance, it may look almost like a FID but is made of STEEL for endurance. MARLINSPIKE (FID) SYNTHETIC ROPE ADVANTAGES 1. Almost impervious to salt, air, water and anything else that could destroy natural line 2. Tougher and stronger for their size than almost any other line material 3. Last a long time 4. Do a better job than any other kind of line SYNTHETIC ROPE DISADVANTAGES 1. It tends to “UNLAY” when cut. 2. Must be whipped or “stopped” immediately. 3. Open flame or Heating iron good for this. 4 TYPES OF SYNTHETIC ROPES 1. NYLON 2. DACRON 3. POLYPROPYLENE 4. POLYETHYLENE ADVANTAGES OF NYLON 1. HIGHEST ELASTICITY 2. CAN ABSORB 7 TIMES SHOCK LOAD OF MANILA 3. USED EXTENSIVELY FOR TOWING AND MOORING 4. HIGH RESISTANCE TO ROT 5. HIGH ABRASIVE RESISTANCE NYLON ADVANTAGES Cont’d 1. Twice as strong as manila 2. Can use nylon of smaller diameter in replacing manila lines 3. Cheaper in the long run 4. Extremely flexible 5. No breaking in period NYLON Disadvantage NOTE MAIN DISADVANTAGE When it reaches the end of it’s elongation, it will SNAP, like a rubber band, becoming extremely dangerous to anybody or thing in it’s path. DACRON 1. Has all the properties of Nylon BUT; is NOT as Elastic 2. Fairly light in weight 3. Mostly has replaced cotton lines on most vessels POLYETHYLENE ADVANTAGES 1. It floats. DISADVANTAGES 1. Low abrasion resistance 2. Not nearly as supple as other synthetics 3. Knots need to be secured POLYPROPYLENE 1. Low abrasion resistance 2. Again not very supple 3. It FLOATS 4. **Stronger when it is wet** WIRE ROPE 1. Generally confined to use on sailing vessels and larger boats. 2. Many strands of wire are wound over an inner core of either wire or fabric such as cotton or a synthetic fabric. 3. The core provides a source of lubrication(when oiled)(or graphite) to ease the friction of the wires and also provides some elasticity or give. WIRE ROPE 5 GRADES RELATIVE TO STRENGTH 1. IMPROVED PLOW STEEL 2. PLOW STEEL 3. MILD PLOW STEEL 4. TRACTION STEEL 5. IRON WIRE ROPE 1. Used where GREAT STRENGTH or HEAVY LOADING is needed, such as STANDING RIGGING and CABLE TOWING 2. Extremely stiff 3. Must use a MARLINSPIKE to work with it 4. Difficult to work with CARING FOR YOUR LINES 1. Neglect can be very expensive. TAKE CARE OF YOUR LINES. 2. DO NOT OVERLOAD: Generally, safe working strength is 1/5 the BREAKING strength. 3. PROTECT AGAINST ABRASION: Always use chaffing gear. 4. AVOID SUDDEN STRAINS ON THE LINE: 5. KEEP YOUR LINES CLEAN: Sand, dirt and grit will grind away the material in a line. Wash them as needed. LINE CARE (Cont’d) 6. STORE YOUR LINES PROPERLY: a. FAKING: YES. When appropriate b. COILING: YES. When appropriate c. FLEMISHING: YES. When appropriate d. CHORDING:NO. Bunched up and thrown into a rope locker! Even when you do it wrong, there is a proper name for it! DO NOT CHORD your lines! . COILED-FLEMISHED-FAKED LINE CARE Cont’d 7. Match your line to the use 8. Keep all chemicals away 9. Avoid excess wear 10. Avoid kinks 11. Don’t run lines over sharp edges PARTS OF A LINE Overhand Working Loop End Underhand Loop Standing Part Bitter End DIPPING THE EYE Used where more than one vessel’s mooring line is used on the same pile. a. DOCKING: Your EYE SPLICE up through the other eye splices – over the top and let settle around the piling. b. UNDOCKING: lift your eye splice up over the piling then pull through other eye splices from the bottom. YOU’RE ON YOUR WAY. DIPPING THE EYE SQUARE (REEF) KNOT 1. Most common way to join two lines of EQUAL DIAMETER together, where no great load is anticipated. 2. The square knot will JAM if heavily loaded, making it almost impossible to break it down without cutting it out. 3. It may also be forced into two half hitches, under great strain. SQUARE KNOT animation BOWLINE 1. Used to form a TEMPORARY LOOP in the end of a line. 2. Won’t slip under a load 3. Easy to tie and untie 4. One of the MOST USEFUL knots we have today. BOWLINE animation HALF HITCH 1. Used in conjunction with other knots. 2. Round turn with two half hitches commonly used as a long term fastening to secure a line to a piling. Round Turn animation Round Turn HALF HITCH animation TWO HALF HITCHES USED TO TIE A LINE TO A RING, PILE, POST OR GROMMET EASY TO UNTIE UNDER TENSION MORE PERMANENT THAN A CLOVE HITCH CLOVE HITCH 1. Used to TEMPORARILY fasten a line to a piling or other attachment. 2. MUST WATCH IT(so that it does not undo). 3. When under a strain, it will not slip. 4. When under a hard strain, it will set up tight and may be difficult to break down. 5. On the other hand, if left slack, it may work itself loose. CLOVE HITCH animation TIMBER HITCH 1. Very useful in towing logs or other similar objects. 2. Fast and easy knot to tie and break down. 3. If you use half hitches with this knot, tie them FIRST , then proceed with the timber hitch. TIMBER HITCH animation ROLLING HITCH 1. A utility knot which can be tied around another line already under strain to maintain the strain. 2. Can be be bent to a spar or other similar object. 3. Used to form a bridle for towing. ROLLING HITCH (UTILITY) SHEET OR BECKET BEND 1. Used to tie two lines of UNEQUAL DIAMETER together. 2. Easy to break down after a heavy strain. 3. DOUBLE BECKET: Simply an extra turn back under and through. SHEET OR BECKET BEND animation DOUBLE BECKET/SHEET BEND SPLICING • Preferred method of joining two lines together 1. EYE SPLICE:To make a PERMANENT EYE at the end. 2. LONG SPLICE: Does NOT increase diameter of the line. Good for use with blocks, sheeves. 3. SHORT SPLICE: May increase lin Preferred method of joining two lines together e diameter and is not used to run through a block, etc. MOORING DEVICES 1. BITTS 2. BOLLARDS 3. CLEATS 4. SAMPSON POSTS BITTS 1. Used to moor large vessels. 2. Normally found on commercial piers. BITTS animation CRUCIFORM BOLLARD CLEAT 1. Found on boats and docks of all sizes. 2. Used to secure lines of all sizes and uses CLEAT animation LARK’S HEAD REVIEW QUESTIONS NO. 1 1. The clove hitch is used to tie a line to a pile or bollard when_______ a. a permanent fastening is required b. when “dipping your line” is required c. securing hemp lines only d. a temporary fastening is desired REVIEW QUESTIONS NO.2 2. Which knot is most useful to temporarily join the ends of different diameter lines? The _________ a. Fisherman’s bend b. Square or Reef knot c. Sheet or Becket Bend d. Sheepshank REVIEW QUESTIONS NO. 3 3. The preferred method of joining rope ends permanently is by use of a ___________ a. knot b. splice c. marlinspike d. turnbuckle REVIEW QUESTIONS NO. 4 4. Which of the following types of line has the highest elasticity? a. Manila b. Dacron c. Cotton d. Nylon REVIEW QUESTIONS NO. 5 5. The most popular and durable of natural fibers used in the manufacture of rope for marine applications is ______ a. flax b. sisal c. cotton d. manila hemp REVIEW QUESTIONS NO. 6 6. The bowline is a knot which is relatively easy to tie and is ______ a. especially useful for forming a temporary loop in the end of a line. b. difficult to untie and tends to slip c. most useful for reefing sails d. never used to tie sheets to the clew of the jib sail REVIEW QUESTIONS NO. 7 7. Cotton rope has about _____ as much strength as compared to manila? a. ¼ b. ½ c. ¾ d. equal REVIEW QUESTIONS NO. 8 8. Rope made of the synthetics Polypropylene and Polyethylene_____ a. are more supple than Dacron and Nylon b. will float c. have a higher abrasion resistance than Dacron or Nylon d. are stronger when wet than when dry REVIEW QUESTIONS NO. 9 9. When laying down a long line on deck for possible full length use, the line should be ______ a. flemished b. faked c. coiled or wrapped d. braided REVIEW QUESTIONS NO. 10 10. Where is Nylon sometimes dangerous? a. in the open sun b. in dark, damp storage c. when tightly spliced d. under a heavy towing load END OF CH. 4