further press information - Emerson Process Management

advertisement

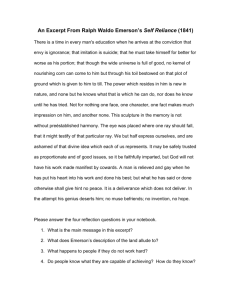

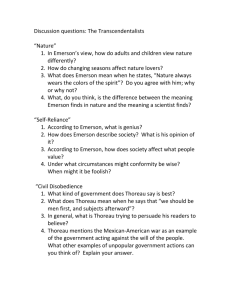

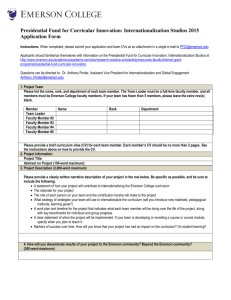

Tüpraş refinery PR (Rosemount Tank Gauging) - Revised 24 Nov 2011 Turkish refinery improves reliability with Emerson’s Smart Wireless technology Selection based on ease of use, cost-effective installation, proven reliability AUSTIN, Texas (Nov. xx, 2011) – The state-owned Tüpraş refinery in Izmir, Turkey, has placed an order with Emerson Process Management for a tank gauging system that includes 85 wireless TankRadar Rex radar level gauges. The order follows Tüpraş Izmir’s extensive testing of 21 additional devices in the same application. The gauging system will provide accurate, reliable level measurements on some of refinery’s most critical oil-movement tanks. The Izmir facility has a refining capacity of 11 million tons/year and storage capacity of 1.9 million cubic meters in 164 tanks -- including 44 lube-oil storage tanks that were already being monitored using wired TankRadar Rex level gauges from Emerson. On other tanks, however, the existing non-Emerson gauging system sometimes had communication problems and gave incorrect readings because of damage to cables during excavations in the field. In addition, support personnel were not always available when needed. Tüpraş first considered replacing the trouble-prone older system with additional wired TankRadar Rex level gauges, which had proven to be very reliable, accurate, and almost maintenance-free since they were installed at the refinery in 2007. Because the tanks are spread over a large area and existing cabling and junction boxes were not up to standard, however, the high cabling and installation costs of this approach made wireless technology more appealing. “Ground conditions make excavation for new cable runs difficult, but with Emerson’s Smart Wireless solution we can minimize costs for cabling, cable trenches, conduits, and cable trays,” said Ali Erener, project chief engineer at Tüpraş Izmir. “Going wireless also gives us the flexibility to add more devices in the future – not only for level and temperature measurements, but also for tank water control and nitrogen pressure control at our blanketing tanks, which are far from the control room, as well as other applications.” The refinery chose Emerson’s solution not only for the proven performance of its wireless technology, but also for ease of use and ongoing support. “Because operations personnel will use the gauging system in their daily work, we required it to be user-friendly,” said operations superintendent Mustafa Atalay, who has worked at Tüpraş Izmir for more than 34 years. “It’s also important to have a good relationship with the supplier to get the most out of the system.” The IEC 62591 (WirelessHART®) field network at the Izmir refinery will have a node for each tank, including a TankRadar Rex radar level gauge installed with an antenna unit, a Smart Wireless THUM Adapter, and a multiple spot temperature sensor to enable accurate volume calculations. Temperature and level data will be sent wirelessly to a Smart Wireless gateway, which serves as the network manager and provides an interface to the refinery’s TankMaster inventory software or control system. The TankMaster software has also been upgraded to include batch calculation for product transfers. For more information about Emerson’s Smart Wireless technology, visit www.EmersonProcess.com/SmartWireless. About Emerson Process Management Emerson Process Management (www.EmersonProcess.com), an Emerson business, is a leader in helping businesses automate their production, processing, and distribution in the chemical, oil and gas, refining, pulp and paper, power, water and wastewater treatment, mining and metals, food and beverage, life sciences, and other industries. The company combines superior products and technology with industry-specific engineering, consulting, project management, and maintenance services. Its brands include PlantWeb™, Syncade™, DeltaV™, Fisher®, Micro Motion®, Rosemount®, Daniel®, Ovation™, and AMS Suite. About Emerson Emerson (NYSE: EMR), based in St. Louis, Missouri (USA), is a global leader in bringing technology and engineering together to provide innovative solutions to customers in industrial, commercial, and consumer markets through its network power, process management, industrial automation, climate technologies, and tools and storage businesses. Sales in fiscal 2010 were $21 billion. For more information, visit www.Emerson.com. PlantWeb, Syncade, DeltaV, Fisher, Micro Motion, Rosemount, Daniel, and Ovation are marks of Emerson Process Management legal entities. WirelessHART is a mark of the HART Communication Foundation. All other marks are the property of their respective owners. _____________________________ Images There are three possible images to accompany this release. The low resolution images can be seen below, and the high resolution images can be opened by clicking on the corresponding link. Caption Ali Erener, project chief engineer, and Ílker Karadağ, operation chief of oil movement together with the antenna unit. The Smart Wireless THUM Adapter transfers tank data via the wireless mesh network to the Smart Wireless Gateway. Link to high resolution image Caption Mustafa Atalay, operation superintendent of oil movement. The TankRadar Rex gauge was qualified for continued refinery operation. Link to high resolution image Caption Link to high Ílker Karadağ, resolution image operation chief of oil movement learns about the batch functionality within the TankMaster software. CONTACT ADDRESSES If you wish to publish for your readers, the contact information is: Emerson Process Management Rosemount Tank Gauging Box 130 45 SE-402 51 Göteborg Sweden E-mail: sales.rtg@emerson.com Web: www.rosemount-tg.com FURTHER PRESS INFORMATION Issued by: Emerson Process Management Rosemount Tank Gauging Box 130 45 SE-402 51 Göteborg Sweden Tel: +46 31 337 00 00 Fax: +46 31 25 30 22 Technical enquiries to: E-mail: Lena Hansson Lena.Hansson@Emerson.com