LBCC - Mod4 Procurement2.0

advertisement

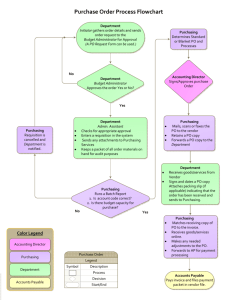

Introduction to Global Supply Chain Management Module Four: Product Procurement & Supplier Relationship Management This project received $24.5M (100% of its total cost) from a grant awarded under TAACCCT, as implemented by the U.S. Department of Labor’s Employment and Training Administration. This is an equal opportunity program and auxiliary aids and services are available upon request to individuals with disabilities. 1 Class Agenda • • Sourcing & Purchasing defined The purchasing function – S&OP integration & synchronization • Key elements of Supplier Relationship Management (SRM) – Strategic considerations – Operational requirements • • Analysis of the purchasing process SRM & Key Performance Indicators 2 Sourcing & Purchasing: Buy-Side Activities In a Global Model S U P P L I E R S MANUFACTURER DISTRIBUTION SYSTEM MATERIALS MANAGEMENT DISTRIBUTION MANAGEMENT Buy Side Sell Side C U S T O M E R S 3 Different Operating Models & Inventory Types Influence Sourcing & Purchasing Strategies Types of Inventory Operating Model • • • • • • • • • • • • • • Raw materials Components/sub-assemblies Work In Process Finished goods Distribution inventory Accessories Spare parts MRO Build to stock Build to order Assemble to Order Engineer to Order Just In Time Vendor Managed Inventories 4 Global Sourcing & Purchasing Defined “The business disciplines of sourcing and purchasing are closely linked in that they are both related to the acquisition of goods & services that contribute to the execution of a company’s business model. Sourcing is a strategic function that establishes the criteria, policies and procedures for selecting and working with both domestic, and overseas suppliers. Executed within the framework of an integrated global supply chain, product sourcing activities include country/region/industry analysis, structural analysis of supplier networks, single vs. multi-vendor sourcing strategies, risk management, logistics & Customs infrastructure, government regulations & tax code, vendor profiles, landed cost analysis, cumulative lead-times, human rights & environmental policies. Conversely, purchasing is involved in the actual procurement of raw materials, components, sub-assemblies, finished goods, accessories and/or service parts in quantities that are the result of ongoing S&OP. Regardless of a company’s business model, purchasing executes on activities that include vendor selection, quality specifications, price & quantity negotiations, terms of sale, shipping terms, cancellation dates, last-ship dates, charge-backs, title transfer, standard operating procedures and documentation requirements.” Dan Gardner, April 2015 5 The Integration of Purchasing With Other S&OP Functions • Whether a company acquires goods through an intercompany purchase or from an outside vendor, the coordination of MRP with other S&OP activities is critical to success – – – – – – • Bill(s) of Material Purchase order management Production planning & MPS Capacity planning Lead time compliance Logistics planning Material Requirements Planning is what drives the purchasing function 6 The Global Purchasing Function & Material Requirements Planning Marketing planning Strategic planning Financial planning Resource planning Production planning Demand management Master production scheduling Routing file Detailed capacity planning Shop-floor systems Bills of material Detailed material planning Front end Inventory status data Time-phased requirement (MRP) records Material and capacity plans Engine Vendor systems Back end 7 MRP & Purchasing: Gross-to-Net Exploding • Gross–to-Net Exploding – An exercise whereby the original (gross) requirement for a product is reduced by: • • • • • • Inventory on hand Confirmed order receipts Confirmed order releases Planned order releases Gross-to-Net Exploding must be integrated with the raw materials inventory management function Integration is achieved through process design and supply chain software applications 8 MRP & Purchasing: Lead Time Off-Setting • Lead time off-setting – Orders are placed for products on a date that “off-sets” cumulative lead times with the desired date of receipt • • • • • • • P.O. preparation/acceptance Production time Transportation lead time Customs clearance Domestics distribution Lead time off-setting must be integrated with the logistics function Integration is achieved through process design and supply chain software applications 9 MRP & Purchasing: A Typical Inbound Supply Chain Supplier Origin Trucker Origin Forwarder International Transportation Origin: Somewhere Overseas CHB U.S. transport W&D Order Fulfillment Last Mile Destination: Somewhere in the U.S.A. Client How MRP Software Helps To Manage The Purchasing Function Item: ABC Order Qty: 1,000 Lead Time: 8 weeks Time Bucket (week) Gross Requirements Scheduled Receipts Projected Available Net Requirements Planned Order Receipt Planned Order Release 1 2 3 4 5 Based on upstream S&OP activities, MRP software nets, offsets, explodes requirements and creates Planned Order Releases. It is the purchasing function that manages the process of converting Planned Releases into Planned Order Receipts and ultimately, into Scheduled Receipts. Integral to that process is the placement of system-driven purchase orders on vendors, as well as making adjustments to to those P.O.’s as new demand information becomes available. 11 Product Procurement & SRM: Strategic Sourcing Considerations 12 Product Procurement & SRM: Complexity & Risk • • • • Many companies buy hundreds (if not thousands) of different products in overseas markets To purchase that many products a firm has to deal with hundreds of active and potential vendors Suppliers can be spread across multiple regions and dozens of countries Vendors have to be vetted and qualified prior to working with them 13 Product Procurement & SRM: Complexity & Risk • • • • • Detailed purchase agreements must be negotiated with each supplier Vendors must be able to work with other supply chain players Detailed Standard Operating Procedures (SOP’s) have to be crafted with each supplier The vendor has to be able to execute Ideally, cloud-based software helps to manage the relationship 14 Product Procurement & SRM: Strategic Sourcing Considerations • • • • • Macro-economic profile (region/country) Industry-specific eco-system Government stability Human rights & environmental issues Proximity to other supply chain players (Tier I, II, III suppliers, customers, ports/airports, 3PL’s etc.) 15 Product Procurement & SRM: Strategic Sourcing Considerations • • • • • • Utilities infrastructure (water, power, et al) I.T. infrastructure Tax structure Demographics Education level Single source or multi-source strategy 16 Product Procurement & SRM: Strategic Sourcing Considerations • • • • • Intra-company or third party sourcing Vendor profile & qualifications Labor costs Unit costs Landed costs 17 Product Procurement & SRM: Strategic Sourcing Considerations • • • • • • Logistics infrastructure Supply chain risk profile Free Trade Agreements Preferential Duty Programs Customs regulations Lead-times 18 The Purchasing Function: Key Considerations in Vendor Selection • • • • • • Ownership structure Financial stability Product portfolio Existing portfolio of clients Technical (engineering) capabilities Location(s) – Possible countries of origin 19 The Purchasing Function: Key Considerations in Vendor Selection • • • • Number of employees Physical plant Production capacity Product quality programs – Lean Manufacturing – Six Sigma • Use of Standard Operating Procedures (SOP’s) 20 The Purchasing Function: Key Considerations in Vendor Selection • • Cost structure (unit cost) Demonstrated S&OP capabilities – MPS, MRP, Capacity Planning • • Supply chain software & visibility tools Knowledge of global trade – Shipping, documentation & compliance 21 The Purchasing Function: Key Considerations in Vendor Selection • • • • Respect for patents, trademarks & intellectual property Human rights compliance Green vendor initiatives Key Performance Indicators – Product quality, quantities, logistics, billing, rejections/returns, et al 22 The Purchasing Function: Contractual Clauses • • • • • • • Product specifications Merchandise description Quality, grade, size & condition Quantities & weights Price Currency of sale Payment terms 23 The Purchasing Function: Contractual Clauses • • • Product warranties & returns Substitution Incoterms® 2010 rule • • • Mode of transport Lead-time Last ship date 24 The Purchasing Function: Contractual Clauses • • • • • • Order cancellation date Charge backs Documentation requirements Dispute resolution Applicable law Severability 25 The Purchasing Process: Alignment, Integration & Synchronization 26 Purchasing Example: Build-to-Order Model Origin Country Suppliers • Buyer places P.O. on vendor • Vendor acknowledges receipt of P.O. • Vendor uploads P.O. in system • Vendor executes MRP • Supplier acquires net raw materials requirements • Completes production process • Supplier prepares commercial documentation In Transit Consolidation Center Destination Country De-Consolidation Center Customer DC Stores • Vendor notifies 3PL and buyer of cargo readiness • 3PL picks up cargo & documentation • 3PL prepares shipment for export • 3PL makes booking with SS Line • 3PL executes export • 3PL send ASN to buyer • Goods are shipped 27 Purchase Order Flowchart Example: Hong Kong to Warsaw Warsaw Buyer Truck Delivery Destination Customs Destination 3PL Airl ine Hong Kong Origin Trucker Origin Customs Supplier Origin 3PL 28 Purchase Order Process Flowchart: Purchasing agent isssues P.O. to buyer Begin Buyer’s system generates Planned Order Release (P.O.R.) Supplier acknowledges reciept of P.O. Purchasing agent reviews P.O.R. Changes required? Yes Negotiate changes No Changes required? Yes Make changes No Vendor inputs P.O. information, S&OP updated No End 29 Purchasing & The “Documentation Trail” • The Documentation Trail is a metaphor that symbolizes the source, creation, use and filing of all documents associated with an international transaction – – – – – – – – – – – Sales contract Purchase orders Commercial invoice Packing list Forwarder’s cargo receipt Ocean bill of lading Airway bill Insurance certificate Certificate of origin Phytosanitary certs Letter of credit Principles That Support The “Documentation Trail” • • • • All information found in export documents should be born of the original contract or agreement One person’s sale is another person’s purchase One person’s export becomes another’s import Different entities in the supply chain use the same information and documents for different reasons – Customs may use a commercial invoice for product classification purposes, while a bank uses it for paying on a letter of credit Principles That Support The “Documentation Trail” • For all of these reasons, all documents have to adhere to “The 3 C’s of Documentation” – Complete – Consistent – Correct • The smallest of errors can stop a supply chain in its tracks – The devil is in the details (and so are the dollars) Document Example: Purchase Order Document Example: Commercial Invoice Document Example: Airway Bill Product Procurement & SRM: Developing Key Performance Indicators 36 Key Performance Indicators (KPI’s) • • • Key Performance Indicators are measurement tools used to quantify performance in specific areas KPI’s should be aligned with the strategic goals of the company The use of KPI’s can be internal and/or external (vendors, etc.) 37 Key Performance Indicators (KPI’s) • KPI’s should be used to measure overall supply chain performance – Buy-Side, Sell-Side, Finance, Customer Service, et al • • KPI’s should be evaluated in periodic business reviews KPI’s can be used as part of a “Supplier Certification” Program 38 KPI’s for Measuring Supplier Performance (Period-Specific) • • Total dollar spend by vendor Landed cost: budget vs. actual – Total – By SKU or part number • • • Number of purchase orders issued Number of SKU’s or part numbers by vendor Dollar value by SKU or part number 39 KPI’s for Measuring Supplier Performance (Period-Specific) • • • • • • Number of incomplete P.O.’s (missing items) Over/under quantities Incorrect merchandise Defective merchandise Damaged merchandise Number/value of insurance claims 40 KPI’s for Measuring Supplier Performance (Period-Specific) • • • • • • Number of changed purchase orders Instances of late shipments Instances of early shipments Number of cancelled orders Products on backorder Dollar value of backorders 41 KPI’s for Measuring Supplier Performance (Period-Specific) • • • • • • Number of rejected purchase orders Missing documents Incorrect prices on invoice Errors on commercial documentation Missed sailings/flights Number of expedited shipments 42 KPI’s for Measuring Supplier Performance (Period-Specific) • • • • Air freight expense for expedited shipments Number of charge-backs Reason for charge-backs Dollar value of charge-backs 43 End of Module Four Congratulations!!!