Bill of Materials (BOM) Table

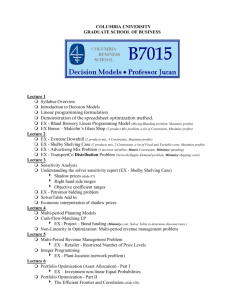

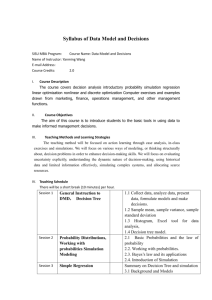

advertisement