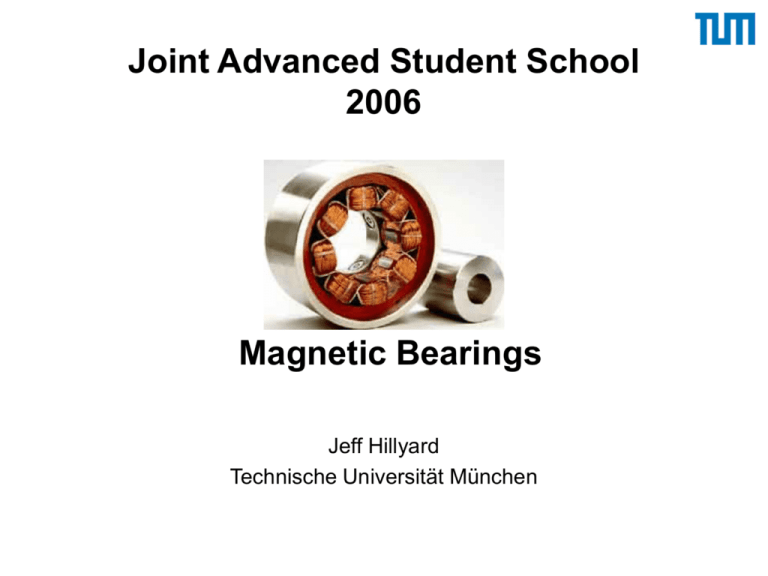

Magnetic Bearings - Technische Universität München

advertisement

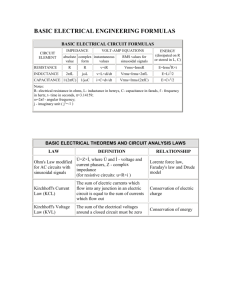

Joint Advanced Student School 2006 Magnetic Bearings Jeff Hillyard Technische Universität München Overview Magnetic Bearings • • • • • Introduction Magnetism Review Active Magnetic Bearings Passive Magnetic Bearings Industry Applications Introduction Magnetic Bearing Types • Active/passive magnetic bearings – electrically controlled – no control system • Radial/axial magnetic bearings Introduction Motivations Advantages of magnetic bearings: contact-free no lubricant (no) maintenance tolerable against heat, cold, vacuum, chemicals low losses very high rotational speeds Disadvantages: Minimum Equipment for AMB complexity high initial cost Source: Betschon Introduction Survey of Magnetic Bearings Source: Schweitzer Magnetism Magnetic Field south pole north pole magnetic field line iron filings Pole Transition Magnetism Magnetic Field Magnetic field, H, is found around a magnet or a current carrying body. H H ds i H i 2r i (for one current loop) Magnetism Magnetic Flux Density B H multiple loops of wire, n B = magnetic flux density = magnetic permeability H = magnetic field 0 r Meissner-Ochsenfeld Effect 0 = permeability of free space r = relative permeability diamagnetic paramagnetic ferromagnetic ni H 2r 1 1 1 Magnetism B-H Diagram Ferromagnetic: a material that can be magnetized Remanence, Br B H magnetic saturation B Coercivity, Hc H area within loop represents hysteresis loss Magnetism Lorentz Force f Q EvB f = force Q = electric charge E = electric field V = velocity of charge Q B = magnetic flux density Magnetism Lorentz Force Simplification: f Q EvB E v B f Q vB Source: MIT Physics Dept. website Magnetism Lorentz Force Further simplification: f Qv B i Qv Analogous Wire B i f f i B force perpendicular to flux! Magnetism Reluctance Force Force resulting from a difference between magnetic permeabilities in the presence of a magnetic field. force perpendicular to surface! The energy in a magnetic field with linear materials is given by: 1 U BHdV 2V U = energy V = volume f U l 2 B A f 2 Magnetism Reluctance Force Basic equation: 1 U BHdV 2V Energy contained within airgap: 1 1 U a Ba H aVa Ba H a Aa 2s 2 2 l Fe 2s Aa Magnetism Reluctance Force Evaluating the magnetic circuit for a simple system: Hds l l Fe B 0 r l Fe 2s Fe H Fe 2sH a ni 2s B 0 ni NI Aa Assumption: B 0 NI l Fe 2 s r BFe AFe Ba Aa BFe Ba B Magnetism Reluctance Force Principle of virtual displacement: U a f BH a Aa l Ha B 0 quadratic! 2 ni Aa cos f 0 l Fe r 2 s i2 f k 2 s 0 inversely quadratic! Active Magnetic Bearings Elements of System • • • • • Electromagnet Rotor Sensor Controller Amplifier Active Magnetic Bearings Force Behavior Magnetic Force 1 2 xs fs Force ~ Force fm Spring Force Distance xs Distance xs Active Magnetic Bearings Force Linearization Magnetic Force fm ~ Spring Force 1 2 xs fs mg mg x0 xs x0 xs Active Magnetic Bearings Force Linearization Operating Point (constant current) Redefining distance: fm f x f ks x x xs x0 x x0 xs ks = force-displacement factor f m, s i m i0 ks x Active Magnetic Bearings Force Linearization Operating Point (constant position) f m ,i im xs x0 ki i i im i0 ki = force-current factor fm ~ im 2 fm f ki i i mg i0 im i0 im Active Magnetic Bearings Force Linearization im Linearized equation: f x, i f m, s i f m, s i f m ,i m i0 xs x0 m i0 f m ,i xs x0 x ks x i im i0 ki i f x, i k s x ki i x xs x0 Not valid for: - rotor-bearing contact - magnetic saturation - small currents Active Magnetic Bearings Closed Control Loop Open Loop Equation: Basic System f x, i k s x ki i i Controller function? - Provide force, f Controller signals? - Input: position, x - Output: current, i i = i(x) x x Artifical damping and stiffness: f kx dx k x d Active Magnetic Bearings Closed Control Loop Solving for controller function: ks x ki i kx dx Basic System i k k s x dx ix x ki x To model position of rotor: f mx f x, i k s x ki i mx k s x ki i Just like for the spring system! mx dx kx 0 Active Magnetic Bearings Closed Control Loop System characteristics: x(t) m2 d k 0 j Ce t with k d2 m 4m 2 d 2m General solution for position: xt Ce t cost Eigenfrequency: 0 2 2 k m t Active Magnetic Bearings Closed Control Loop Controller Abilities: 1) 2) 3) 4) k, d can be varied in controller air gap can be varied in controller specify position for different loads rotor balancing, vibrations, monitoring... Active Magnetic Bearings Closed Control Loop Differential driving mode Linearization: magnetic force was determined to be 2 f 1 i 0 n 2 Aa cos 4 s i2 f k 2 cos s where 1 k 0 n 2 Aa 4 i0 ix 2 i0 ix 2 cos f x f f k 2 2 s0 x s0 x s s0 x s s0 x Active Magnetic Bearings Closed Control Loop Differential driving mode Linearization: f x fx ix x0 f x ix x x x0 4ki0 4ki0 2 f x 2 cos ix 3 cos x s0 s0 ki f x ki i x k s x ks linearized for differential driving mode Active Magnetic Bearings Bearing Geometry Radial Bearing Axial Bearing Active Magnetic Bearings Bearing Geometry B circumferential to rotor axis B parallel to rotor axis - similar to electromotors - rotor requires lamination - hysteresis loss low - lamination avoided Orientation: magnet pole pairs are often lined up with the principle coordinate axes x and y (vertical and horizontal) control equations are simplified Active Magnetic Bearings Sensors Position Sensor • contact-free • measure rotating surface + – surface quality – homogeneity of surface material – various values Other Sensors • speed • current • flux density • temperature • … …other concerns: observability placement cost sensor Active Magnetic Bearings Sensors “Sensorless“ Bearing - calculate position - less equipment - lower cost Source: Hoffmann Active Magnetic Bearings Amplifier Converts control signals to control currents. Analog Amplifier: Switching Amplifier: - simple structure - low power applications P<0.6 kVA - lower losses - high power applications - remagnetization loss Active Magnetic Bearings Electrical Response There is an inherent delay in the electrical system inductance di voltage drops: u L L dt and uR Ri Total voltage drop: di u Ri L ku x dt ku = voltage-velocity coefficient velocity within magnetic field induces a voltage Active Magnetic Bearings Control Equations of Motion Block diagram with voltage control: di u Ri L ku x dt f ( x, i) ks x ki i mx f Source: Schweitzer Active Magnetic Bearings Current vs. Voltage Control Voltage Control: - more accurate model - better stability - low stiffness easier to realize - voltage amplifier often more convenient - possible to avoid using position sensor Current Control: - simple control plant description - simple PD or PID control Flux Control: - very uncommon Active Magnetic Bearings Addressing of Assumptions Uncertainties in bearing model - leakage flux outside of air gap - air gap is bigger than assumed - iron cross section is non-uniform Active Magnetic Bearings Types of Losses Air Losses - air friction divide shaft into sections Copper Losses (Stator) 2 - wire resistance PCu RCu i Iron Losses (Rotor) - hysteresis (higher w/ switching amplifier) - eddy currents Active Magnetic Bearings Copper Losses For differential driving mode: PCu ,max 2RCu imax 2 An K n Ad n NI max PCu ,max An K n 2 lm An = slot area Kn = bulk factor = specific resistance lm = average length of turn limit of permissible mmf! Active Magnetic Bearings Rotor Dynamics Areas of Consideration • • • • • natural vibrations forward/backward whirl (natural vibrations) critical speeds nutation precession (change in rotation axis) Source: Wikipedia Active Magnetic Bearings Rotor Dynamics rotor touch-down in retainer bearings - maintenance - sudden system shutoff - during system shutdown very difficult to simulate cylindrical motion conical motion Source: Schweizer Active Magnetic Bearings Rotor Stresses Radial 2 2 2 ri ra 1 2 2 r 3 ri ra 2 r 2 8 r Tangential 2 2 ri ra 1 2 2 2 t 3 ri ra 3 2 1 3 r 2 8 r Source: Schweizer largest stress is at inside radius of disc with hole! Active Magnetic Bearings Rotor Stresses Implications of max stress: max velocity (full disc)! vmax ra 8 S 3 s = max tensile strength Material steel brass bronze aluminium titanium soft ferro. sheets vmax (m/s) 576 376 434 593 695 565 Actual reached speeds (length 600 mm, dia. 45 mm): vmax 300 m s max 120,000rpm Source: Schweizer Passive Magnetic Bearings Permanent Magnets Common Materials: 1) 2) Relative Sizes neodymium, iron, boron (Nd Fe B) samarium, cobalt, boron (Sm Co, Sm Co B) 3) 4) ferrite aluminium, nickel, cobalt (Al Ni, Al Ni Co) Issues: - material brittleness - varying space requirements (B-H) - operating temperatures (equal H at 10 mm) Passive Magnetic Bearings Permanent Magnets at least one degree of freedom unstable! increase in stiffness with multiple rings caution: misalignment! reluctance bearings: - non-rotating magnets - resistance to radial displacement Passive Magnetic Bearings Permanent Magnets High Potential - economical - reliable - practical already replacing some active magnetic bearings - smaller size equipment and systems - systems with large air gaps Source: Boden Applications Turbomolecular Pump École Polytechnique Fédérale de Lausanne, Switzerland - eliminates complicated lubrication system - high temperature resistance - reduction of pollution - vibrations, noise, stresses avoided - improved monitoring (unbalances, defects, etc.) Status: suboptimal design overheating at load (> 550°C) increase life span optimize fill factor reduce cost simplify manufacturing Applications Flywheel (‘97) New Energy and Industrial Technology Development Organization (NEDO) – Japan‘s Ministry of International Trade and Industry (MITI) • • • • T=½J2 speed has larger influence than mass (better energy density) fiber-reinforced plastics for high strength fracture into small pieces upon failure above ground combination of superconductor and permanent magnet bearings (hsys = 84%) Applications Flywheel (‘97) Current Development Goals (NEDO) • • • • increase load force reduce amount load force decrease with time (magnetic flux creep) reduce rotational loss increase size of bearings for larger systems Applications Maglev Trains Maglev = Magnetic Levitation • 150 mm levitation over guideway track undisturbed from small obstacles (snow, debris, etc.) • typical ave. speed of 350 km/h (max 500 km/h) what if? Paris-Moscow in 7 hr 10 min (2495 km)! • stator: track, rotor: magnets on train Source: DiscoveryChannel.com Applications Maglev Trainsx Maglev in Shanghai - complete in 2004 - airport to financial district (30 km) - world‘s fastest maglev in commercial operation (501 km/h) - service speed of 430 km/h Source: www.monorails.org Applications Maglev Trains Noise Reduction by Frequency Noise Reduction by Speed Source: Moon Magnetic Bearings References 1. Betschon, F. Design Principles of Integrated Magnetic Bearings, Diss. ETH. Nr. 13643, ETH Zürich, 2000. 2. Boden, K. & Fremerey, J.K. Industrial Realization of the “SYSTEM KFA-JÜLICH“ Permanent Magnet Bearing Lines, Proceedings of MAG ‘92 Magnetic Bearings, Magnetic Drives and Dry Gas Seals Conference & Exhibition. Lancaster: Technomic Publishing, 1998. 3. Electricity and Magnetism. Hyperphysics. Georgia State University, Dept. of Physics and Astronomy. 1 Apr. 2006 <http://hyperphysics.phy-astr.gsu.edu/Hbase/hph.html>. 4. Fremery, J.K. Permanentmagnetische Lager. Forshungszentrum Jülich, Zentralabteilung Technologie, 2000. 5. Hoffmann, K.J. Integrierte aktive Magnetlager, Diss. TU Darmstadt. Herdecke: GCA-Verlag 1999. 6. Lösch, F. Identification and Automated Controller Design for Active Magnetic Bearing Systems, Diss. ETH. Nr. 14474, ETH Zürich, 2002. 7. Maglev Monorails of the World: Shanghai, China. The Monorail Society Website. 1 Apr. 2006 <http://www.monorails.org/tMspages/MagShang.html>. 8. Maglev Train Explained, DiscoveryChannel.ca. Bell Globemedia 2005 <http://discoverychannel.ca/interactives/japan/maglev/maglev.html>. 9. Magnetic Bearings & High Speed Motors, S2M. 1 Apr. 2006 <http://www.s2m.fr/chap3/>. Magnetic Bearings References 10. Moon, F.C. Superconducting Levitation: Applications to Bearings and Magnetic Transportation. New York: John Wiley & Sons, 1994. 11. Research and Development for Superconducting Bearing Technology for Flywheel Electric Energy Storage System. New Energy and Industrial Technology Development Organization (NEDO). 1 Apr. 2006 <http://www.nedo.go.jp/english/activities/2_sinenergy/1/p04033e.html>. 12. Schwall, R. Power Systems – Other Applications: Flywheels. Power Applications of Superconductivity in Japan and Germany. WTEC Hyper-Librarian 1997 <http://www.wtec.org/loyola/scpa/04_02.htm>. 13. Schweizer, G., Bleuler, H., & Traxler, A. Active Magnetic Bearings: Basics, Properties and Applications of Active Magnetic Bearings. Zürich: Hochschulverlag AG an der ETH, 1994. 14. Widbro, L. Magnetic Bearings Come of Age. Revolve Magnetic Bearings Inc. 2004. MachineDesign.com. 1 Apr. 2006 <http://www.machinedesign.com/ASP/strArticleID/57263/strSite/MDSite/viewSelectedArticle.asp>. 15. Wikipedia contributors (2006). Hysteresis. Wikipedia, The Free Encyclopedia. April 1, 2006 <http://en.wikipedia.org/w/index.php?title=Hysteresis&oldid=45621877>. 16. Wikipedia contributors (2006). Magnetic field. Wikipedia, The Free Encyclopedia. April 1, 2006 <http://en.wikipedia.org/w/index.php?title=Magnetic_field&oldid=46010831 >. Questions? Applications Crystal Growing System