Discover Mechatronics

advertisement

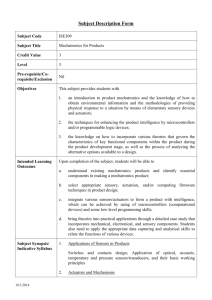

Industry-Based Modularized Accelerated Credentials IMAC Goal …..Increase access of working adults to training and credentials for high wage, high demand jobs in critical industry sectors such as advanced manufacturing….. Features 1. Flexibility and Convenience 2. Interactive Learning 3. Hands-on “Real World” Training 4. College Credit Flexibility and Convenience IMAC Offers Students: Self-Paced Learning --Web-based and Hands-on Accelerated Courses Multiple Learning Sites -- Home, College, and Work Evening and Weekend Lab Hours Instructional Assistance The training equipment pictured above is manufactured by Amatrol, Inc. Interactive Learning Students learn theory and concepts through state-ofthe-art web-based learning programs. Both one-on-one and small group instructional assistance is available when students need it. The web-based course content pictured above is a registered product of Amatrol, Inc. Hands-on Training Students gain crucial “realworld” skills by learning the operation, maintenance and troubleshooting of hightech integrated systems prevalent in advanced manufacturing. The training equipment pictured above is manufactured by Amatrol, Inc. College Credit Credentials: •Industrial Maintenance Certificate: 11-22 Credits •Industrial Maintenance Technician Diploma: 48-60 Credits •Associate in Applied Science (GOTS) Degree: 60-76 Credits Courses Industrial Maintenance Principles Fluid Power PLCs Industrial Maintenance Rotating Machinery Motor Controls Assessment/Tracking Comprehensive Assessment/Tracking Computerized Quizzes and Exams Corresponds with demonstration of skills Progress Tracking and Reporting Skills Objectives Student Project Grading Activities Assessment The Learning Management System pictured above is a registered product of Amatrol, Inc. Results Pilot launched in August 2005. 35 Dislocated Workers and IndustrySponsored Participants in program to date 3 students graduated with honors during OCTC’s 2007 graduation ceremonies earning an AAS degree, diploma, and certificate 11 students have earned certificates 14 students have completed a course for a skill upgrade 3 students are currently working toward AAS degrees 1 student is currently working toward a certificate 3 students have dropped out of the cohorts before completing a course Industry sponsors include Aleris, Century Aluminum, Domtar, Unilever Mechatronics Mechatronics is a blend of mechanical, electrical/electronic and computer technologies. Mechatronics simplified, is a mechanical function carried out through the use of input signals delivered to a decision making device (PLC/CPU) that commands an output for a mechanical function to occur. Examples of Mechatronic Systems: There are thousands of Mechatronic applications, from the automobiles we drive to the household appliances we use. Mechatronics in Manufacturing Today’s manufacturing and packaging processes have become increasingly complex. Manufacturing industries depend heavily on automated process to compete globally. Automated manufacturing equipment are “smart” machines requiring higher skill level operators. As “baby-boomers” retire manufacturers are faced with identifying and hiring highly skilled personnel, knowledgeable in advanced manufacturing concepts and competencies. Enter: Discover Mechatronics – Next Generation Manufacturing OCTC’s Discover Mechatronics – Next Generation Manufacturing was developed to expose feeder high schools students in the OCTC service area to the exciting field of advanced manufacturing. OCTC’s Discover Mechatronics – Next Generation Manufacturing is a comprehensive recruitment model designed to ensure an increased number of students, entering the high performance workplace of advanced manufacturing. Activities were developed with industry input from the Greater Owensboro Economic Development Corporation and partnering industries. The project is funded by the National Science Foundation. Discover Mechatronics Activities Discover Mechatronics courses have been developed and included into current dual enrollment offerings through the college’s Discover College program. Discover Mechatronics Career Academies are scheduled to be conducted to expose 22 feeder high schools students in the OCTC service area to the exciting field of advanced manufacturing. Discover Mechatronics Clubs are being developed at each of OCTC’s 22 feeder high schools to raise awareness and support youth involvement. Mechatronics Curriculum Mechatronic Systems Operating Technician: Level I Course Title MS110 MS120 MS130 MS150 Credit Hours Mechatronic Systems Electrical Components Mechatronic Systems Mechanical Components Mechatronic Systems Hyd/Pneu Components Mechatronic Systems Programmable Controllers Total Credits Electives: MS160 Systems Troubleshooting I MS190 Systems Thinking 4 4 4 4 16 2 1 Discover Mechatronics Product Manufacturing Students learn real life manufacturing through the process of automated component assembly. Discover Mechatronics Lab Special designed lab simulates manufacturing process using the “Systems Approach” The training equipment pictured above is manufactured by Amatrol, Inc. Discover Mechatronics Lab Individual Work Stations The training equipment pictured above is manufactured by Amatrol, Inc. Discover Mechatronics Lab Students learn advanced manufacturing technology on integrated systems for operating, troubleshooting, and maintaining systems. The training equipment pictured above is manufactured by Amatrol, Inc. Results for Discover Mechatronics – Next Generation Manufacturing Pilot launched in August 2007 Hired Mechatronics instructor and recruiter 10 area high school students enrolled in first semester Establishing Discover Mechatronics Clubs in service area high schools Coordinating student retention activities Developing manufacturing internship with area industries