Control Devices

advertisement

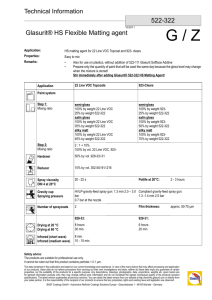

A Wastewater Solution for an Air Pollution Problem A Cost-Effective Alternative for VOC Control as Required by NESHAP [BWON, HON, MON, MACT] Dr. Carl E. Adams, Jr., PE, BCEE Senior Author1 * Dr. Lial F. Tischler2 Andrew W. Edwards, PE3 1 2 3 ENVIRON International Corporation, Nashville, TN Tischler/Kocurek, Austin, Texas ENVIRON International Corporation, Houston, TX BWON (Benzene Waste Operations NESHAP) Aqueous Wastewater Considerations − Influent wastewater benzene concentration must be <10 mg/L to avoid required regulatory inventory accounting procedures − Wastewater treatment bioplant must qualify as an Enhanced Biodegradation Treatment Unit (EBU) − Current approved control is by excellent benzene separation in production processes and use of a NESHAPS Benzene Steam Striper on benzene-laden wastewaters Wastewater Gaseous Emissions Considerations − Applies to gaseous emissions from wastewater treatment processes − Includes API separators, dissolved air and induced air flotation processes, uncovered tanks and includes sumps and wet wells emissions − Must incorporate an approved Control Device to reduce benzene emissions form these sources by 98% − Current approved controls are thermal oxidizers and vapor-phase activated carbon BWON (Benzene Waste Operations NESHAP) Wastewater Gaseous Emissions Considerations Title 40: Protection of Environment: 40 CFR § 61.340 presents three basic Control Devices that are acceptable, pursuant to specific design constraints: (i) An enclosed combustion device (e.g., vapor incinerator, boiler, or process heater) (ii) A vapor recovery system (e.g., a carbon adsorption system or a condenser) (iii)A flare Title 40: Protection of Environment: 40 CFR § 61.340 also states “other” Control Devices can be used provided that certain conditions are met. (iv) A control device other than those described in paragraphs (a)(2) (i) through (iii) of this section may be used provided that the following conditions are met: BWON (Benzene Waste Operations NESHAP) Wastewater Gaseous Emissions Considerations (A) The device shall recover or control the organic emissions vented to it with an efficiency of 95 weight percent or greater, or shall recover or control the benzene emissions vented to it with an efficiency of 98 weight percent or greater. (B) The owner or operator shall develop test data and design information that documents the control will achieve an emission control efficiency of either 95 percent or greater for organic compounds or 98 percent or greater for benzene. (C) The owner or operator shall identify: 1) The critical operating parameters that affect the emission control performance of the device; 2) The range of values of these operating parameters that ensure the emission control efficiency specified in paragraph (a)(2)(iv)(A) of this is maintained during operation of the device; and 3) How these operating parameter will be monitored to ensure the proper operation and maintenance of the device. Overview From Nashville, TN: The idea To Garyville, LA: The testing site and first case study To Research Triangle, NC (USEPA): The endorsement To Baton Rouge, LA (LDEQ): The final approval To Austin, TX: ENVIRON workshop To weekly conference calls: VOC BioTreat™ Core Group To creating marketing solutions: Brand, media relations, collateral To prestigious recognition: AAEE E3 Grand Prize for Research To today: Learn what you can; communicate to your contacts; bring in Carl, Greg or Andy Prestigious Accolade: National Grand Prize – Research Category 2011 VOC BioTreat has garnered the coveted National Grand Prize in the Research category of the prestigious American Academy of Environmental Engineers (AAEE) 2011 Excellence in Environmental Engineering® (E3) Competition. The concept was conceived, developed and implemented by Dr. Carl E. Adams, Jr., Global Practice Area Leader: Industrial Wastewater Management. Kirkpatrick Award: Semifinalist Kirkpatrick Chemical Engineering Achievement Award recognizes the most innovative chemical engineering technology achieved through group effort and successfully commercialized worldwide during the two years prior to an award year. Chemical Engineering Magazine has awarded this biennial prize continuously since 1933. VOC BioTreat was the 2011 Semi-Finalist Louisiana Section of the Air & Waste Management Association: 2011 Industry Award: Grand Prize VOC BioTreat Technical Presentations and Publications “A Cost-Effective Alternative for VOC Control as Required by NESHAP [BWON, HON, MON, MACT],” AIChE Workshop, Baton Rouge, LA, November 11, 2011. “Innovative Cost-Effective Control Device for Wastewater VOC Emissions (As Required by NESHAPs [BWON, HON, MON, MACT] and Other Regulations),” ENVIRON, Houston, Texas, November 3, 2011. “Innovative Cost-Effective Control Device for Wastewater VOC Emissions (As Required by NESHAPs [BWON, HON, MON, MACT] and Other Regulations),”WEFTEC 2011, October 17, Los Angeles, California. “Innovative Cost-Effective Control Device for Wastewater VOC Emissions (As Required by NESHAPs [BWON, HON, MON, MACT] and Other Regulations)”, CHEMINNOVATIONS Conference & Expo and the collocated ISA Houston Section Conference & Expo., Houston, TX, George R. Brown Convention Center, Chemical Engineering Magazine, September 13 - 15, 2011. "A Cost Effective Alternative for VOC Control as Required by NESHAP [BWON, HON, MON, MACT, RACT and Other Regulations," Air & Waste Management Association's Annual Conference & Exhibition, Orlando, FL on June 21-24, 2011. “Biological Control of Benzene-Containing Off Gases”, Petroleum Environmental Research Forum, San Ramon, California, June 15, 2011. “Patented & Innovative Cost-Saving Control Device for Facility-Generated Volatile Organic Compound (VOC) Emissions”, American Academy of Environmental Engineers, Excellence In Environmental Engineering, Conference Agenda National Press Club, Washington, D.C., May 4, 2011. VOC BioTreat Technical Presentations and Publications (cont’d) “Innovative Cost-Effective Control Device for Wastewater VOC Emissions (As Required by NESHAPs [BWON, HON, MON, MACT] and Other Regulations)”, Chemical Engineering Magazine VOC BioTreat Interview, April 15, 2011. Environmental News Record, interview for magazine with Gary Tulacz, April 1, 2011. “A Cost-Effective Alternative for VOC Control as Required by NESHAP [BWON, HON, MON, MACT]”, Annual Mid-Western Air & Waste Management Association's Annual Conference & Exhibition, Kansas City, December 2010. “Innovative Cost-Effective Control Device for Wastewater VOC Emissions (As Required by NESHAPs [BWON, HON, MON, MACT] and Other Regulations)”, Annual 2010 National Petroleum Refiners Association Environmental Conference, San Antonio, TX, September 20-21, 2010. “A Cost-Effective Alternative for VOC Control as Required by NESHAP [BWON, HON, MON, MACT]”, Annual Conference +American Petroleum Institute’s Environmental Committee, Garyville, LA, June 2010. “A Cost-Effective Alternative for VOC Control as Required by NESHAP [BWON, HON, MON, MACT]”, AIChE Workshop, Chicago, IL, November 10, 2011. “ENVIRON VOC BioTreat, Un sistema innovativo per il controllo delle emissiona di VOC, Italian Environmental Engineers Association (Aria y Aqua), Remtech, Ferrara, Itlay, Oct 2011. POSTER SESSION. “Treating Volatile Organics in Activated Sludge Treatment”, Indian Environmental Association, Annual Conference “EnviroVision2011, Advances in Environmental Technologies & Management, Ahmedabad, India, 24 th-26th Nov, 2011. What is VOC BioTreat ? TM What is VOC BioTreat? • VOC BioTreat is the process of qualifying an Alternative Control Device, other than Activated Carbon or Thermal Oxidation, for the biodestruction of regulated biodegradable VOC emissions. • The Alternative Control Device is cost-effectively an existing activated sludge process with emission sources in proximity to a WWTP. Typical Acceptable Control Devices Thermal Oxidizers: Flare or Gaseous Incinerator Thermal Oxidizers Vapor-Phase Adsorption: Granular Activated Carbon Granular Activated Carbon Canisters Alternative Control Device Alternative Control Device for a Refinery: A Basic Overview COMBINED WASTEWATER & AIR VOC BIOTREATMENT USING EXISTING FACILITIES Air VOC Emissions Piped to Existing Bio-Blowers EQ Tank SITE PROCESS/ STORMWATER WASTEWATERS Dissolved Nitrogen Flotation Unit Activated Sludge Bioreactor P-52 Secondary Clarifier API Separator API Entry Well Site Process / Stormwater Sump Ambient Air Inlet to Blower API Effluent Well API Pump Well DNF Wet Well Appropriate Valving & LEL Instrumentation Recycled Biomass FINAL EFFLUENT A Cost-Effective Solution for the Biodestruction of VOC Emissions • Incorporates ENVIRON-developed protocols to demonstrate an Alternative Control Device • Confirms the use of existing biological wastewater treatment facilities • Follows exact EPA requirements and protocols for approval A Cost-Effective Solution for the Biodestruction of VOC Emissions • Conclusively demonstrates co-treatment of gaseous emissions or VOCs and aqueous soluble organics in existing wastewater treatment facilities • Using these protocols, most activated sludge biotreatment systems can be qualified as an Alternative Control Device to treat biodegradable VOCs • It is transferable to other VOC/HAP and other regulations • Provides excellent configuration flexibility with existing facilities Regulatory Interface & Approval Regulatory Approval Regulatory Interface & Approval Specific projects State of Louisiana State of Wyoming: in process of approval State of Mississippi: in process of approval Regular invitation to ENVIRON USEPA Research Triangle Park: Presented as a Technical Seminars(2) USEPA region 5: Presented as a Technical Seminar USEPA region 6: Presented as a Technical Seminar USEPA region 7: Presented as a Technical Seminar USEPA region 8: Presented as a Technical Seminar Why VOC BioTreat ? TM Why VOC BioTreat? • Economics, Economics, Economics!!! – Typical systems (carbon or TOs) have much higher operating costs • O&M costs are typically <$10K per year – Capital investment quickly recovered (ROI <1 year typically, <2 yrs worst case) – Discarding previously installed system carbon/TO ok • OK, it’s not all economics! – N2 blankets: expensive, maintenance issue, leakage (pressurized) – Sustainable at reduced costs VOC BioTreat Application Industrial Sectors • • • • • Refineries: BWON Organic Chemicals: MACT (e.g., HON, MON, etc) Pharmaceuticals: Pharma MACT Coke plants (steel industry): BWON Soil-Vapor-Extraction remediation systems Regulatory Drivers • Alternative NESHAP Wastewater Emission Control • WWTP Compliance Assurance Monitoring Optimization (CAM) for biological destruction efficiency (Fbio) • Process Vent Control VOC BioTreat Typical Applications Soil-Vapor-Extraction VOC BioTreat Projects in 2011 Client Location Industrial Classification 3M Corporation Advocacy Project w/PERF Air Products & Chemicals Celanese Corporation Chevron Refining ConocoPhillips-Alliance DuPont Corporation ExxonMobil Refining Frontier Refining HEXION Marathon Petroleum Marathon Petroleum Marathon Petroleum Marathon Petroleum NOVACHEM SABIC Shell Chemical Co. Shell Oil Co. TEVA US Steel Valero Refining Valero Refining Valero Refining Cordova, IL Oakland, CA Calvert City, KY Meredosia, IL Pascagoula, MS Belle Chasse, LA Kinston, NC Baton Rouge, LA Cheyenne, WO Louisville, KY Robinson, IL Texas City, TX Detroit, MI Garyville, LA Red Deer, Canada Ottawa, IL Deer Park, TX Australia Mexico, MO Gary, IN Houston, TX Pt. Arthur, TX Corpus Christi, TX Organic Chemicals Refinery Organic Chemcials Organic Chemicals Refinery Refinery Organic chemicals Refinery Refinery Organic Chemicals Refinery Refinery Refinery Refinery Ethylene Refinery Organic Chemicals Organic Chemicals Refinery Pharmaceuticals Coking Facility Refinery Refinery Refinery Conclusions VOC BioTreat – the Process TM How is it Applicable? High-Level Assessment: Comprehensive Questionnaire • Existing WWTP amenable to the technology? – Diffused aeration system – Deep tanks – Existing blowers have adequate air flow treatment capacity (modification may be necessary) • VOC emission sources appropriate for technology? – Compounds relatively biodegradable – Compounds have sufficient solubility (relatively low Henry’s Law constants) – VOC air volume compatible with WWTP diffused air treatment capacity • Favorable economics? – Reasonable proximity of VOC sources to WWTP – Current system O&M costs – Minimal modifications required to adapt WWTP to technology VOC BioTreat – The Process STEP 1 High-Level Feasibility Evaluation STEP 2 Develop preliminary facility-specific model with assumed biodegradation rate to gauge benzene removal performance requirements and obtain initial Agency concurrence for approach STEP 3 Conduct BOX testing to determine site-specific VOC biodegradation rate and maximize VOC BioTreat effectiveness STEP 4 Conduct Core Column Simulation Full-scale confirmation testing STEP 5 Obtain final Agency approval of Alternative Control Device STEP 6 Prepare detailed engineering plan and implement Alternative Control Device solution Steps 1 & 2 must be concluded favorably before proceeding with the remaining steps. Case History Marathon Petroleum Company Garyville Refinery (MPC) Garyville, Louisiana Petroleum Refinery: BWON Alternative Control Device Why was MPC-Garyville an Excellent Choice? • Economics, Economics, Economics! − Current MPC system had very high operating cost (energy and carbon) − Discarding initial capital investment wasn’t a deal breaker − BioTreat alternative costs almost nothing to operate • OK, it wasn’t all economics! − N2 blanket system leakage degrading overall performance of current system (not an issue for BioTreat alternative) − Reduction in carbon footprint, better sustainability aspects − Substantial reduction in energy requirements − Simplicity of installation and operation of BioTreat alternative (maintenance cost likely much lower) Current/Proposed Benzene Control Devices MPC asked ENVIRON to develop protocols to qualify the existing activated sludge system (AIS) as an Alternative Control Device. MPC Case History – Economic Economic Impacts for VOC Control Devices MPC – Garyville Refinery WWTP COST-EFFECTIVE IMPACT PROCESS TECHNOLOGY Capital cost ($) Annual operating cost ($) Thermal Oxidizer 600,000 340,000 240,000 500,000 350,000 Minimal Granular Activated Carbon (6 carbon canisters on each of two API separators, 22 change-outs/yr per API) + Maintenance of N2 blanket Biological (piping, fans and connection to blowers) MPC Case History – Sustainability Economic Impacts for VOC Control Devices MPC – Garyville Refinery WWTP ANNUAL IMPACT Process Technology Thermal Oxidizer (calculated) Granular Activated Carbon (in operation) Energy Consumption CO2 Emissions Million BTUs per year Tons CO2 per year 45,700 2,690 192 10 Minimal Minimal Biological (no additional energy required or CO2 generated, due to minimal organics being treated) Proposed Alternative Control Device BioReactor Construction UNICELL Induced Air Flotation (IGF) Marathon Petroleum Company Garyville, Louisiana Refinery Closed-Circuit Cooling Tower Reliable Data on Benzene Critical Benzene Mass Balance for MPC–Garyville Inputs to Site-Specific Model Major Variables Other Significant Variables Benzene Biodegradation Rate • Air Distribution in Zones − Table 2 represents various experimentally-determined biorates from API and ENVIRON databases Air Flow Biomass Concentrations Potential Benzene Injection Locations into AIS Benzene Loadings & Mass Balance • Depth of BioReactor • Aeration Tank Surface Area • Temperature • Hydraulic Flow Rate & COD Loading Models for Calculating VOC BioTreat™ Emissions Applicable models − EPA WATER9 − TOXCHEM+ − BASTE TOXCHEM+ is preferred – can simulate vapor to liquid phase transfer All are identified in 40 CFR 63 Appendix C as “acceptable” for HAP emissions calculations for biological treatment Units All three models calculate the following: VOC emission rates (g/sec, tons/yr) − Fractions of influent VOC mass loading emitted, biodegraded, and discharged-overall and for each process unit individually Model inputs: − Site-specific physical and operating characteristics − Site-specific compound biorates (each has default rates) BWON Modeling Benzene Biodegradation Rates BENZENE BIODEGRADATION RATES – EXPERIMENTAL VALUES K1 (L/g VSS-hr) @ 20 oC Data referred to as API is from Table 5 of the API/NPRA comments to EPA dated December 28, 2007. Refinery Test Type Date Runs Average for Multiple Runs Value Selected for Model Evaluation API-A BOX Nov-06 2 48.9 ----- API-A Method 304A Nov-06 1 120.1 84.5 API -B BOX Oct-97 1 79.1 79.1 API-C BOX Oct-97 2 78.4 78.4 API-D EKR Jul-96 4 17.3 17.3 API-D BOX Jul-96 5 122 ----- API-E BOX Sept-94 5 122 ----- API-E BOX Nov-94 2 31 ----- API-E BOX Dec-94 6 199 ----- API-E BOX Apr-95 5 199 ----- API-E BOX Apr-95 7 172 API-E BOX Jun-95 4 206 185.5 API-F BOX Jul-95 3 4.4 4.4 Mar-00 3 64 64 API-G ENVIRON-1 BOX Jul-09 2 23.4 23.4 ENVIRON-2 BOX Mar-11 1 19.7 19.7 ENVIRON-3 BOX Aug-11 1 10.8 10.8 ENVIRON-4 BOX Aug-11 1 6.4 6.4 API Water 9 Default Rate (EPA requires that Default Rate be used if industry chooses not to conduct BOX Test to determine site-specific benzene biodegradation rate. 1.4 Benzene Removal with Preliminarily Assumed Rates vs. Actual Site-Specific Rate (Corrected to 20°C) Develop Site-Specific Biodegradation Rate; Select Appropriate EPA-Recommended Approach Source: EPA 40 CFR part 63, Appendix C, Figure 1 Develop Site-Specific Biodegradation Rate BOX Test Apparatus that is typically used Typical BOX Test Apparatus Option 1 Typical BOX Test Apparatus Option 2 Develop Site-Specific Biodegradation Rate BOX Test Apparatus Developed by ENVIRON Develop Site-Specific Biodegradation Rate BOX Test Column (without aeration) Air Supply Tank (Supplies BOX Test Column & GC) Fine-Bubble Air Diffuser (Off) Develop Site-Specific Biodegradation Rate Voyager Photovac Online Photo-ionization GC Sample Syringes BENZENE IN OFF-GAS EMISSIONS (ppmv) Comparative Results of Benzene Stripping with and without Biomass 250 WITHOUT BIOMASS ~2 mg/L Benzene added to filtered effluent 200 150 WITH BIOMASS ~2 mg/L Benzene added to biomass MLVSS concentration of 800 mg/L 100 50 0 0 50 100 150 200 TIME (min) 250 300 350 400 450 Development of Preliminary Site-Specific Benzene Control Model Rerun Calibrated Model with Site-Specific Biodegradation Rate • The site-specific biodegradation rate, corrected to 20°C, is – 22.6 L/g VSS-hr @ 20°C at Marathon-Garyville • The Toxchem+ model will adjust the rate to the selected temperature for full-scale operating conditions Benzene Removal with Preliminarily Assumed Rates vs. Actual Site-Specific Rate (corrected to 20°C) Full-Scale Confirmation Flux Chamber: Less Desirable Option Full-Scale Confirmation Performance Validation of Full-Scale System Using VOC BioTreat Column Protocols Full-Scale Confirmation Off-gas vent Sample gas line to on-line gc Gravity overflow line back to full-scale aerobic zone Recycle biomass Port Influent Wastewater Sample port Support pipe (empty) Drain Aeration + Benzene input Full-Scale Confirmation Performance Validation of Full-Scale System Using VOC BioTreat Column Protocols Full-Scale Confirmation Full-Scale Confirmation Results Benzene analytical results of full-scale confirmation Run # Benzene Concentration ppbv Outlet Blower Inlet Vent Benzene Biodestruction (%) Percent of Design Condition Performance Versus Regulatory Requirements 1 21 < 2.0 > 90.6 100% Inconclusive due to analytical limitations 3A 121 < 2.0 > 98.3 >500% Exceeds 3B 153 < 2.0 > 98.7 >700% Exceeds 4A 156 < 2.0 > 98.7 >700% Exceeds 4B 482 13.3 > 97.2 >2200% Below 5A 182 < 2.0 > 98.9 >800% Exceeds 5B 226 < 2.0 > 99.1 >1000% Exceeds Design is 98% at inlet of 14 ppb. Results showed 16 times that capacity. Breakthrough at ~400-500 ppbv. Regulatory Approval Repeat of Slide 15 Case History Economic Evaluations for Sustainability Confirmation Western Refinery, Wyoming, USA: 65,000 bbls/day Case History – Economic Economic Impacts for VOC Control Devices Cost-Effective Impact Process Technology Capital cost ($) Annual Operating Cost ($) Granular Activated Carbon (2 large carbon vessels on DAFs, multiple other carbon canisters; over 300,000 lbs/yr activated carbon consumption w/ no reactivation option) 200,000 780,000 VOC BioTreat (validation, engineering piping, instrumentation, and connection to blowers) 460,000 < 10,000 Energy Savings / Sustainability Aspects Case Study No. 2: Replace Activated Carbon Canisters at Wyoming Refinery Sustainability Aspects Case Study Scenario Benzene Control Technology Energy Consumption Activity Total Energy Usage (mmBTU/year) Carbon Emissions (tons CO2/year) Transport to/from Reactivation Facility 547 63 Reactivation Process (315,000 lbs/yr) 1,859 116 Totals 2,406 179 8.1 2.5 2,398 177 Activated Carbon Canisters Current Control System VOC BioTreat Alternative Biological Treatment in WWTP Additional Power for Aeration Blowers Total Energy Savings / GHG reductions Current Benzene Vapor Controls: SE, USA Refinery (Activated Carbon Canisters), 350,000 bbls/day Main Sump BOTTOMS API #7 FLOAT 3 DNF Units CPI #6 = 2,000 lb Canister = 1,000 lb Canister = 20,000 lb Container API #2 API #1 Energy Savings / Sustainability Aspects, SE USA Case Study No. 3: Replace Activated Carbon Canisters at Mississippi Refinery Sustainability Aspects Case Study Scenario Benzene Control Technology Energy Consumption Activity Total Energy Usage (mmBTU/year) Carbon Emissions (tons CO2/year) 422 146 Reactivation Process 1,564 98 Totals 1,985 244 10.8 1.0 1,974 243 Activated Carbon Canisters Transport to/from Reactivation Facility Current Control System VOC BioTreat Alternative Biological Treatment in WWTP Additional Power for Aeration Blowers Total Energy Savings / GHG reductions Redirect Vent Stream from Flare to Biological WWTP, MidWest, USA, Refinery, 200,000 bbls/day Energy Savings / Sustainability Aspects MidWest Refinery, USA Case Study No. 4: Replace Small Dedicated Flare at Illinois Refinery Sustainability Aspects Case Study Scenario Benzene Control Technology Energy Consumption Activity Total Energy Usage (mmBTU/year) Carbon Emissions (tons CO2/year) 48,640 2,860 Steam Assist and Blower 10,648 632 Totals 59,288 3,492 13.0 4.0 59,275 3,488 Steam-Assisted Flare Nat. Gas Pilot and Refinery Fuel Gas Current Control System VOC BioTreat Alternative Biological Treatment in WWTP Additional Power for Aeration Blowers Total Energy Savings / GHG reductions Schematic of Wastewater Treatment Plant with Current Benzene Vapor Controls (8,000 scfm RTO) RTO Energy Savings / Sustainability Aspects, SW Refinery, 350,000 bbls/day Case Study No. 5: Replace regenerative Thermal Oxidizer at Texas Refinery Sustainability Aspects Case Study Scenario Benzene Control Technology Energy Consumption Activity Total Energy Usage (mmBTU/year) Carbon Emissions (tons CO2/year) 12,960 765 260 80 13,219 845 15.2 4.7 13,204 840 Regenerative Thermal Oxidizer Supplemental Fuel (nat. gas) Current Control System Electric Power for RTO Blower Totals VOC BioTreat Alternative Biological Treatment in WWTP Additional Power for Aeration Blowers Total Energy Savings / GHG reductions Questions & Answers