safety data sheets (SDS) - Tarleton State University

advertisement

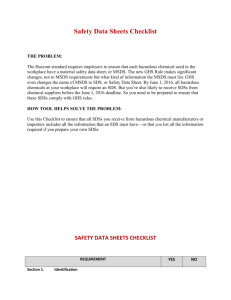

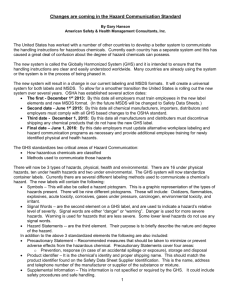

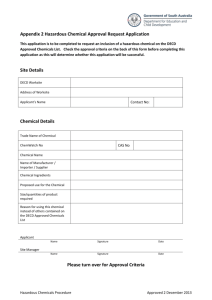

HAZARD COMMUNICATION DEPARTMENT OF RISK MANAGEMENT AND SAFETY SAFETY CONTACTS • Emergency (Fire, Police, Medical) 911 • Poison Control Center (800) 222-1222 • UPD (non-emergency) (254) 968-9002 • Control Center (after-hours, weekends, holidays) (254) 968-9265 • RMS (8 – 5, Monday through Friday) (254) 968-9842 / 9237 / 9429 / 9898 • E-mail hcdavis@tarleton.edu, lockenour@tarleton.edu, cjordan@tarleton.edu. wkstyron@tarleton.edu • Facilities Maintenance (repair call) (254) 968-9065 PURPOSE OF HAZARD COMMUNICATION To ensure that employers and employees know about work hazards and how to protect themselves so that the incidence of illnesses and injuries due to hazardous chemicals is reduced. TEXAS HAZARD COMMUNICATION Applies to all employees working for this state who may be exposed to hazardous chemicals under normal operating conditions or foreseeable emergencies TEXAS HAZARD COMMUNICATION ACT An official Texas Department of State Health Services “Notice to Employees” must be posted at the location(s) within each workplace where notices are normally posted EMPLOYEE RIGHTS As an employee, you have a right to know about the hazardous materials used in your work area and the potential effects of these materials upon your health and safety. • Employees have rights to: o Access copies of MSDS (Material Safety Data Sheets)/SDS (Safety Data Sheets) o Information on their chemical exposures o Receive training on chemical hazards o Receive appropriate protective equipment o File complaints, assist inspectors, or testify against their employer without fear of reprisal HAZCOM REQUIREMENTS FOR TARLETON STATE UNIVERSITY Provide information to employees on the hazards of chemicals they work with or may be exposed to and how they can protect themselves from these hazards. Make this information available by compiling chemical inventory lists, by conducting training programs, by maintaining MSDS/SDS files, and by properly labeling containers. CHEMICAL INVENTORY The Act requires employers to compile and maintain a workplace chemical list that is to be updated at least annually and be readily available to employees upon request. Information on the workplace inventory form shall include: • The common name and chemical name used on MSDS/SDS and container labels • The product name and hazardous ingredients • The work areas where the chemical/product is stored or used • The quantity of the chemical/product Items intended for personal consumption by employees are exempt from the provisions of the Hazard Communication Act. TRAINING REQUIREMENTS Other times you may be required to complete additional training may include: • Beginning a new assignment which requires use of a hazardous chemical • Whenever a new or increased hazard is introduced • Whenever new and significant hazard information is received for a chemical in the work area GENERAL SAFETY TRAINING This presentation covers the general requirements you will need to know concerning working with hazardous chemicals: • Information on MSDS/SDS and how to obtain them • Information on labels • Generic information on hazardous chemicals • First Aid • Personal Protective Equipment (PPE) • Chemical spill clean-up • Chemical Waste Disposal WORK AREA SPECIFIC TRAINING Your supervisor may cover topics concerning jobsite specific requirements you will need to know: • Information on hazardous chemicals • Location of MSDS/SDS • PPE • First Aid • Spill Clean-up • Chemical Waste Disposal MATERIAL SAFETY DATA SHEET/SAFETY DATA SHEET REQUIREMENT • Readily Accessible o Work Area File o Manufacturer/Distributor o RMS: (254) 968-9842 / 9237 / 9429 / 9898 o http://msdssearch.com/find.htm • MSDS/SDS for each and every chemical product MSDS/SDS FORMAT EFFECTIVE JUNE 1, 2015 Chemical manufacturers or importers shall ensure that MSDS/SDS for their products include the following sections in order: • Identification of substance or mixture and the supplier • Hazard identification • Composition/information on ingredients • First aid measures • Fire-fighting measures • Accidental release measures • Handling and storage • Exposure control/personal protection • Physical and chemical properties • Stability and reactivity • Toxicological information • Ecological information • Disposal information • Transport information • Regulatory information • Other information, including preparation or last revision of SDS PRIMARY CONTAINER LABELING In addition to the MSDS/SDS, many times you can find the applicable hazards, identity and chemical manufacturer on the primary container label: Hazards Identity Manufacturer LABELING – NFPA 704 In addition to MSDS/SDS and primary container labeling, you can also obtain information on a chemical or material using the NFPA 704 label system: Flash Point 4-Below 73oF 3-Below 100oF 2-Above 100oF Not Exceeding 200oF 1-Above 200oF 0-Will Not Burn OX-Oxidizer 4-May Detonate ACID-Acid 3-Shock and Heat May Detonate ALK-Alkali W-Use no Water 2-Violent Chemical Change 1-Unstable if Heated 0-Stable LABELING – DEPARTMENT OF TRANSPORTATION (DOT) These are examples of DOT labels, which are used during the transport of chemicals and hazardous materials: GLOBALLY HARMONIZED SYSTEM (GHS) Soon mandatory for ALL chemical products sold in the U.S. GHS standardizes chemical labels and safety data sheets (SDS), formerly known as material safety data sheets (MSDS), to better communicate hazards to employees. • Provided below are links to GHS documents from OSHA and the U.N. OSHA Guide to the GHS U.N. Guide to the GHS GLOBALLY HARMONIZED SYSTEM (GHS) GHS labels must include six elements, the 1st three of which are standardized: 1. Symbols (Hazard pictograms): visually convey health, physical and environmental hazard information. May Cause Cancer 2. Signal word: "Danger" or "Warning“ emphasize hazards and indicate the relative level of severity. 3. Hazard statement: standard phrases describe the nature of the hazard. The standardized pictograms, signal words, and hazard statements should be located together on the label, but the label format or layout is not specified. 4. Precautionary statement: linked to each GHS hazard statement and type of hazard, these mostly standard phrases describe measures to minimize or prevent adverse effects, including first aid. 5. Product identifier: should match the SDS (MSDS) 6. Supplier identification: Name, address, and telephone number of the manufacturer, importer, or other responsible party. Next, let’s take a closer look at the first four label elements. GLOBALLY HARMONIZED SYSTEM (GHS) A Pictogram is a symbol that conveys visual cues about the hazards of a chemical. Eight pictograms are designated by OSHA and GHS. Here are four of the five assigned to already be familiar with them, but examine their lists of associated hazards. physical hazards . You may COLOR: The OSHA standard does not assign colors to hazard classes. • The colors shown above are roughly equivalent to those used in Department of Transportation (DOT) shipping labels and placard s. • The National Fire Protection Association (NFPA) uses blue for health, red for flammability and yellow for instability. GLOBALLY HARMONIZED SYSTEM (GHS) Four pictograms are assigned to health hazards . The skull & crossbones symbol is familiar, but the others may not be so obvious. “Corrosion” can be both a physical and a health hazard. MULTIPLE HAZARD CLASSES: A product may have more than one hazard class, so two or more pictograms may appear on a label. SIMPLE ASPHYXIANTS: GHS has no pictogram for these substances that displace oxygen and can cause oxygen deprivation/death. GLOBALLY HARMONIZED SYSTEM (GHS) Signal word indicates the relative level of severity of hazard. The two standard GHS signal words are: “DANGER” – used for the more severe hazards. When you see “DANGER,” be especially careful with handling or using as it may cause devastating physical effects (e.g., explosion; fire; severe burns or eye damage), or be fatal or severely toxic to an exposed person. “WARNING” – used for the less severe hazards, such as combustible materials or those that are harmful or irritating to an exposed person. A signal word may not appear for some lower level hazard categories. Nevertheless, be cautious and follow directions when using or handling any chemical product. DANGER Warning! GHS does not specify color or font, so the signal word, if there is one, may be prominent, or it may be somewhat hard to find on the label. GLOBALLY HARMONIZED SYSTEM (GHS) Hazard statement describes the nature of the hazard(s) of a chemical, including, where appropriate, the degree of hazard, “1” being the worst. Hazard statements are short, standardized phrases categorized as: • Physical hazard statements (29 in all) or • Health hazard statements (52 in all) A single product may have one, two or even several hazard statements. In this example, each hazard statement is set apart by bullets. GLOBALLY HARMONIZED SYSTEM (GHS) Precautionary statement describes recommended measures to minimize or prevent adverse effects resulting from exposure or from improper storage or handling. There are five types of precautionary statements: 1. General; 2. Prevention; 3. Response (in case of accidental spillage or exposure, emergency response and first-aid); 4. Storage; and 5. Disposal. On a label, they may be in a table, a list, or combined for readability or to save space. Precautionary statements are selected from a large, coded list of standard phrases, but manufacturers may remove or add words or descriptions. GLOBALLY HARMONIZED SYSTEM (GHS) Let’s put it all together on a real product label. Here is an example of an actual GHS LABEL for TOLUENE KEY TO GHS LABEL ELEMENTS 11. Pictograms depicting hazards, in this case, from left to right: flammable, chronic health hazard, acute health hazard; 2. Signal word, either DANGER or WARNING; 3. Hazard statement: a written list of associated hazards; 4. Precautionary statements related to the hazard; 55. Product identifier and codes, in this case the name of the compound and its synonyms; and 6. Supplier information. 5 1 GLOBALLY HARMONIZED SYSTEM (GHS) EXAMPLE of an actual GHS LABEL for TOLUENE 1. 2. 2 3. 3 4. 4 5. 6. 6 Pictograms depicting hazards Signal word, either DANGER or WARNING; Hazard statement: a written list of hazards; Precautionary statements related to the hazard; Product identifier and codes; and Supplier information. 6 2 3 4 GLOBALLY HARMONIZED SYSTEM (GHS) GHS Classification Criteria • Unlike many systems where hazard severity increases from low to high numbers, GHS is the opposite, with Category 1 being highest risk and higher numbers indicating lower risk. • Let’s illustrate with GHS categories of acute toxicity as in Section 2 of an SDS. Route of Exposure LD50 (oral) or LC50 (inhalation) Category 1 Category 2 Category 3 Category 4 (MOST SEVERE) Category 5 (RELATIVELY LOW ACUTE TOXICITY) Oral (mg/kg) ≤5 >5 ≤ 50 > 50 ≤ 300 > 300 ≤ 2000 Gases (ppm) ≤ 100 > 100 ≤ 500 > 500 ≤ 2500 > 2500 ≤ 5000 Criteria: • Oral LD50 from 2000 and 5000 mg/kg; • Significant effect in humans; • Any mortality / clinical signs at class 4. LD50 (abbreviation for “lethal dose, 50%”) or LC50 (lethal concentration, 50%) is the that kills half the members of a test group. LD50 / LC50 can be found in Section 11 of an SDS. GLOBALLY HARMONIZED SYSTEM (GHS) Other Toxicity Hazard Rating Systems To get an intuitive sense of acute toxicity, compare the GHS categories for ingestion to information provided by the National Research Council. Comparison of LD50 to Probable Lethal Dose for Humans GHS Toxicity Category NRC Toxicity Rating Animal LD50 (per kg body wt.) Category 1 Extremely toxic <5 mg A taste (<7 drops; <0.4 ml) Category 2 Highly toxic 5 to 50 mg Between 7 drops and 1 tsp (0.4 to 5 ml) Category 3 – 4 Moderately toxic 50 to 500 mg Between 1 tsp and 1 oz (5 to 30 ml) Category 4 – 5 Slightly toxic 500 mg to 5 g Between 1 oz and 1 pint (30 – 500 ml) Practically nontoxic >5 g Lethal Dose When Ingested by a 150-lb (70-kg) Human >1 pint (>500 ml) Adapted from: National Research Council. 2011. Prudent Practices in the Laboratory: Handling and Management of Chemical Hazards: Updated Version. Committee on Prudent Practices in the Laboratory. Washington, DC: National Academies Press. CHEMICAL STORAGE When not in immediate use, all chemicals should be properly stored. This means that they should be stored in an appropriate location, off of the floor with other compatible chemicals – and away from incompatible chemicals. Chemicals should never be stored alphabetically! • Store by hazard class • Date when received and when opened • Keep from heat/sunlight • Label properly (secondary container) • Minimize quantities • Do not store flammables in household refrigerator or freezer • Protect against spills • Dispose of outdated, questionable or unneeded chemicals WHAT’S WRONG WITH THIS PICTURE? Many times, there can be dangers which are not readily apparent: • Chemical staining outside bottle • Open date not documented • Old crystallizing chemicals WHAT’S WRONG WITH THIS PICTURE Some dangers are immediately visible! • No catch basin or absorbents • Spills • Build-up on bottles WHAT’S WRONG WITH THIS PICTURE Improper storage can also be very dangerous! Storage of chemicals on the floor or outside of a proper container can lead to accidents and spills. ACCIDENTS HAPPEN WHEN SAFETY IS NOT IMBEDDED INTO YOUR PROCESSES PROTECTIVE MEASURES / HAZARD REDUCTION Through training and communication you can learn the proper methods to reduce hazards and protect yourself while working with chemicals. Listed below are several ways that you can protect your health and physical safety while using hazardous materials: • Personal monitoring • Personal protective equipment (PPE) • Product substitution • Safe work practices • Engineering controls • Chemical substitution • Exhaust system PERSONAL PROTECTIVE EQUIPMENT • Equipment designed to protect the user from hazards of the chemical or material. • To find out what PPE is necessary for a particular chemical or material refer to the MSDS/SDS. • PPE information is listed under exposure limits and personal protection. PERSONAL PROTECTIVE EQUIPMENT • Eyes o Safety Glasses, Chemical Splash Goggles, Full Face Shield (with protective eyewear) • Hands o Appropriate Type of Gloves • Body o Lab Coat, Apron, Tie Long Hair Back, Closed Toe Shoes, and Other Appropriate Clothing • Respiratory o Dust Mask, Full and Half Face Respirators, SCBA WHAT IS A HAZARDOUS CHEMICAL? Any element, chemical compound or mixture of elements or compounds that is a physical hazard or a health hazard. COMMON EXAMPLES OF HAZARDOUS CHEMICALS • Fuels • Cleaning Products • Compressed Gases • Pesticides/Herbicides • Laboratory Chemicals • Solvents • Many types of oils and paints • Cement • Refrigerant • Welding Rods HELPFUL DEFINITIONS • Health Hazard – a health hazard includes chemicals which are carcinogens, toxic or highly toxic agents, reproductive toxins, irritants, corrosives, sensitizers, hepatotoxins, nephrotoxins, neurotoxins, agents which act on the hemopoietic system and agents which damage the lungs, skin, eyes or mucous membranes. • Physical Hazard – a physical hazard includes chemicals which are a combustible liquid, a compressed gas, an explosive, a flammable, an organic peroxide, an oxidizer, pyrophoric, an unstable (reactive) or water reactive. • Work Area – a work area is a defined space within a workplace where hazardous chemicals are produced, used, or stored and employees are present. • Workplace – an establishment at one geographical location containing one or more work areas. TYPES OF HEALTH HAZARDS • Corrosive – destroy tissue at the point of contact (acids, bases, dehydrating agents, strong oxidizing agents) • Reactive – undergo violent reaction under certain conditions (explosive, rapid polymerization, water reactive, air reactive, strong oxidizers) • Flammable – any liquid with a flashpoint below 100 F (differs from combustible liquid), or a solid that is liable to cause fires through friction/absorption of moisture, etc./can be readily ignited. • Toxic – substance that is harmful to living organisms because of its detrimental effects on tissues, organs, or biological processes. • Carcinogen – a chemical known or believed to cause cancer in humans. ACUTE EFFECTS The acute effects of a chemical are the symptoms that occur immediately or very soon after you come into contact with them. The acute effects of a chemical can be found on the MSDS/SDS. Know all the acute effects of the material before work begins. Examples of some acute effects that a person may experience include: • Skin irritation • Dizziness • Burning sensations CHRONIC EFFECTS The chronic effects of a chemical are the symptoms that result from long-term exposure to a substance. • Any chronic effect that a chemical might cause can be found on the MSDS/SDS. • Know the short and long term effects of a chemical before you use it. • If the chemical is unknown, treat it as if it poses an immediate and long term health hazard. • Most harmful effects can be prevented or greatly reduced by simply wearing the proper PPE. WORKING WITH CORROSIVES • Protect Eyes and Skin • Large Quantities - wear protective clothing • Dilution WHEN CONTACT WITH CORROSIVES OCCUR: • Remove contaminated clothing • Rinse in safety shower or eyewash for at least 15 minutes • Seek Medical Attention WORKING WITH REACTIVES • Preplan to reduce exposure • Isolate from cause of reaction • Storage o Separate from other chemicals o Keep in Cool/dry area o Out of sunlight IF REACTION OCCURS: o Emergency Equipment • Refer to MSDS/SDS for required equipment o Contact • Flush for 15 minutes (except with water reactives) WORKING WITH FLAMMABLES • Remove Ignition Source (heat or spark) • Keep away from oxidizers and combustible materials • Work in a fume hood or a well ventilated area • Be familiar with operation and location of fire extinguisher, building alarms and evacuation procedures • Storage: o Well ventilated area o Flammable storage cabinet o Lab-safe refrigerator o Isolated from incompatible chemicals WORKING WITH TOXINS • Read MSDS/SDS for exposure limits and proper handling information • Use Fume Hood if available • Proper Protective Gear • No food or drinks while working • Safe levels of exposure are established by three entities: NIOSH, OSHA, and ACGIH* • o REL – Recommended Exposure Limit (NIOSH) o PEL – Permissible Exposure Limit (OSHA) o TLV – Threshold Limit Value (ACGIH) Types of Toxins o Carcinogens - cause growth of abnormal tissue o Reproductive Toxins - interfere with reproduction of adult o Teratogens - interfere with embryo/fetus development o Mutagens - alters DNA o Neurotoxins - damage nervous system *NIOSH, OSHA and ACGIH are the regulatory agencies that establish occupational exposure limits for employees working with che micals FIRST AID • Remove contaminated clothing • Refer to MSDS/SDS for chemical specific first aid • Medical attention call 911 ROUTES OF EXPOSURE There are several ways chemicals can get into the body an cause harm. The common routes of entry into the body are through: Inhalation Skin absorption Ingestion INHALATION Inhalation is the most common route of exposure. This includes breathing in dust, fumes, oil mist, and vapors from solvents and various gases. To prevent this always read the precautions on labels or MSDS/SDS and wear the appropriate PPE. SKIN ABSORPTION • Some chemicals are readily absorbed into the body through contact with the skin. • Always look under the occupational exposure limits on the MSDS/SDS to see if the chemical is readily absorbed by the skin. • It is very important to wear all the appropriate PPE while working with this type of hazardous material. INGESTION • To avoid accidental/indirect ingestion: o Never eat foods, drink or put anything in your mouth in areas where chemicals are used o Never smoke in areas where chemicals are used o Wash your hands and face with soap and water after working with chemicals before you eat, drink, smoke or apply cosmetics, etc. EMERGENCY EQUIPMENT Areas around emergency equipment such as showers, eyewashes, fire extinguishers and emergency electrical cutoffs must be kept clear. Accidents occur without warning. All users should know what emergency equipment is available and where it is located. SAFETY EQUIPMENT TO LOOK FOR CHEMICAL SPILL CLEAN UP Rule of thumb: you can clean the spill up yourself if it can be done without hurting yourself or others and it’s not an emergency or likely to become an emergency. If not, call 911. If you do clean it up you’re still required to call Risk Management & Safety. CHEMICAL SPILL CLEAN UP • Develop plan of action o Know when to call for HELP! o How to contain spill o Who is responsible for the clean up o How to Decontaminate the area • Identify the chemical • Protect yourself • Notify others • Attend to injured or exposed CONCLUSION • Know safety contacts and phone numbers • Report all accidents immediately • Be sure to get appropriate training when a new hazard in introduced • Always use a current MSDS/SDS to know the characteristics and specific hazards of each chemical you will be working with • Know proper first aid procedures for each chemical you will be working with • Know where your safety equipment is located and how to use it • Label all containers with their contents • Practice proper chemical storage and handling • Know the hazards and risks in your work area and the consequences of an accident or spill • Wear the proper protective equipment at all times PROPERTIES On passing, 'Finish' button: On failing, 'Finish' button: Allow user to leave quiz: User may view slides after quiz: User may attempt quiz: Goes to Next Slide Goes to Next Slide After user has completed quiz At any time Unlimited times