Heat Capacity Ratio of a Perfect Gas Questions

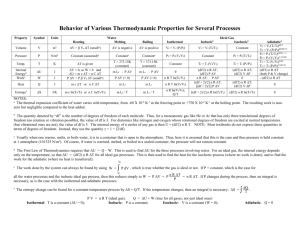

advertisement

Questions 1. Why can the initial expansion process be considered as adiabatic? An adiabatic process means that no heat transfer occurs between a system and its surroundings [1]. Normally a change in pressure is associated with a change in temperature, but since the pressure was not very high and when releasing the pressure through the valve V1, the release in pressure was so rapid that the temperature change can be considered negligible. Due to these the initial expansion was adiabatic. 2. Explain what you mean by Cp and Cv. When we use the variables Cp and Cv we are referring to the specific heat capacity under different conditions. When using Cp we consider the specific heat capacity under constant pressure, whereas Cv is the specific heat capacity under constant volume. [2] 3. How well do the results obtained compare to the expected result? Give possible reasons for any difference. Our results yielded a significantly high percent error for each run, but after speaking with a teaching assistant, we learned our results were similar to the results obtained by previous groups doing this experiment. Our average percent error for the five recorded trial runs was 33.68%. We conducted a number of different runs in an attempt to get the most accurate results possible and fix any potential errors we may have had in the first few test runs. Runs 1, 2 and 4 gave us a higher value of 𝛾𝑜 than we would have liked. Runs 3 and 5 gave us our closest results to the actual value of 𝛾𝑜 . Our high error percentage is possibly due to human error. During the experiment we were required to quickly get a read off of the LCD monitor on the IFD5 after the pressure was rapidly released. Reading off the display may have resulted in the wrong data being recorded. The experiment also took place on a very hot day which had different ambient conditions than the theoretical testing conditions. Based on our initial Ohm reading from the IFD5, we could conclude the room was around 28°C where the theoretical conditions were measured at 25°C. This was figured out by using the chart provided by Dr. Kassegne in the lab instructions [3]. 4. Comment on any differences in the transient responses of the pressure and temperature sensors. The transient response of the pressure and temperature in the experiment were observed in two ways. The first way was on the IFD5, where a small LCD display would present the readout of the pressure or temperature depending on what setting the device was set to via the frontal knob. The second and more accurate was seen and recorded by the computer hooked up to the IFD5. The transient response of the pressure was set up on the computer to take and record a reading every second. The data from the pressure readings fluctuated and slowly dropped until stabilizing once the system came to equilibrium. The temperature did not fluctuate very much over time due to ambient conditions, although hot, remaining constant throughout the experiment. The pressure sensor fluctuated more than the temperature sensor due to the increase of air being pumped in and out of the pressure chamber. The pressure would slowly drop over time due the air inside the chamber trying to reach equilibrium. In an ideal situation, both the pressure and temperature sensors would respond in the same way. In this experiment, the pressure drop is significantly larger than the temperature drop, so we neglected the temperature change over time. [1] Moran, M. J., & Shapiro, H. N. (2008). Fundamentals of Engineering Thermodynamics (6th ed.). USA: Wiley. [2] Incropera, F. P. (2007). Fundamentals of Heat and Mass Transfer (6th ed.). USA: Wiley. [3] Kassegne, S. “ME495 Lab - Heat Capacity Ratio of Perfect Gas - Expt Number 6." Mechanical Engineering Department. San Diego State University. Fall 2011.