TECHNOLOGY AND STRUCTURE

advertisement

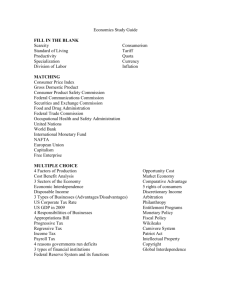

TECHNOLOGY AND STRUCTURE TECHNOLOGY THEORISTS 1. Joan Woodward 2. Charles Perrow 3. James Thompson Joan Woodward In the early 1960’s Woodward demonstrated that organization structures adapt to their technology. In categorizing companies into three groups she identified that production run sizes were linked increasing levels of complexity and technological sophistication. Technology Categories Unit Production: The production of items in single units and small batches Mass Production: The production of large-batch manufacturing Process Production: The production of continuous -process products such as oil and chemical refiners Production Systems by Number Employed WOODWARD: TECHNOLOGICAL INFLUENCE ON ORGANIZATIONAL DESIGN 1. The more complex the technology – going from a Unit to a more Process system – the greater are the number of managerial personnel and the levels of authority 2. The more complex the technology, the larger is the number of clerical and administrative personnel 3. The span of control of first-line managers increases from Unit production systems to Mass production systems and then decreases from Mass production systems to Process production systems MASS PRODUCTION TECHNOLOGY & DESIGN UNIT & PROCESS TECHNOLOGY & DESIGN COMPUTER-INTEGRATED MANUFACTURING Since the work of Woodward, there have been significant advances in production technology, which include the use of robots, numerically-controlled machine tools, and many applications of the computer to remote control of equipment. These advances have been called by a variety of names including: advanced manufacturing technology, agile manufacturing, smart factories, and flexible manufacturing systems. Computer-Integrated Manufacturing Typically the results of three sub-components: 1. Computer-assisted design (CAD). Computers are used to assist in drafting, design and engineering of new parts. Allows significant variation in specifications with minimum of redesign cost. 2. Computer-aided manufacturing (CAM). Computercontrolled machines are used in materials-handling, fabrication, production, and assembly. Allows fast switching between product runs and variations. Computer-Integrated Manufacturing, cont’d 3. Integrated Information Networks (ERP): A computerized system links all aspects of the firm – accounting, marketing, purchasing, inventory control, etc. The most common are called Enterprise Resource Planning programs. Most known are by SAP, PeopleSoft and Oracle. Use a common database, and allow managers to integrate their decision making more effectively. NEW CHOICES Customized Small Batch Flexible Manufacturing Mass Customization Product flexibility Mass Production OLD CHOICES Continuous Process Standardized Small Batch Size Unlimited Comparison of Organizational Characteristics of Mass Production vs CIM Structure Mass Production Span of control Hierarchical levels Tasks Specialization Decision Making Overall Wide Many Routine, repetitive High Centralized Bureaucratic, mechanistic CIM Narrow Few Adaptive, craftlike Low Decentralized Self-regulating, organic Charles Perrow Focus is on departmental technology and departmental structure (usually outside the technical core) Each department has a production process with a distinct technology Includes units such as HRM, R&D, legal, engineering, QC, finance, etc. DIMENSIONS OF TECHNOLOGY Task Variety: number of exceptions in the work. Frequency of unexpected and novel events that occur in the conversion process. Problem Analyzability: degree to which work activities and problem solving activities are analyzable. Analyzable problems can be solved with procedures and standardized technical knowledge. Non-analyzable problems must be dealt with by wisdom, experience and intuition. PERROW - CONCLUSIONS 1. Departments do differ from one another and can be categorized by their workflow technology. 2. Structural and management processes differ based upon workflow technology. 3. Managers should design departments so that requirements based on technology can be met. 4. Explains differences in departmental structures in mixed-type designs. JAMES THOMPSON – TECHNOLOGY SYSTEMS THEORIST SYSTEMS MODEL OF ORGANIZATION Departmental Interdependence Interdependence mean the extent to which departments depend on each other for resources or materials to accomplish their tasks. Low interdependence means the departments can do their work independently of each other and have little need for interaction, consultation or exchange of materials. High interdependence means the departments must constantly exchange resources. Types of Interdependency • Pooled Interdependency • Sequential Interdependency • Reciprocal Interdependency Pooled Interdependency Pooled interdependence is the lowest form of interdependence among departments. In this form, work does not flow between units. Each contributes to the common good of the organization, but does its work independently. Examples: McDonald’s restaurants, branch banks, independent sales units based upon territory or product lines. Mediating Technology Pooled interdependence is associated with organizations employing a Mediating Technology. A Mediating Technology provides products or services that mediate or link clients from the external environment and, in doing so, allows each department to work independently. Banks, brokerage houses, real estate offices all mediate between buyers and sellers, but the offices work independently within the organization. Mediating Technology II To achieve coordination, mediating technologies rely on both a measure of categorization and a degree of standardization. Organizations with mediating technologies are, in general, moderately flexible to changing product demands and typically cope with uncertainty by increasing the number of units served. Since mediating technology combines the outputs of different units by using predetermined categories and standard rules and procedures, it is usually less costly than long-linked technology which requires a certain amount of planning (scheduling) across several tasks to ensure proper work flow. Sequential Interdependence Sequential interdependence exists when the outputs of one department become the inputs of another in serial form. This is a higher level of interdependence than pooled relationships. The preceding unit must complete its tasks correctly in order that the latter unit may successfully complete its tasks. It creates a higher need for horizontal integration mechanisms. Sequential interdependence is associated with Long-Linked Technologies.. Long-Linked Technology Long-linked technology is usually associated with large organizations that utilize sequential task organization, such as assembly lines to accomplish their tasks. Examples include the manufacture of automobiles, heavy appliances, mechanical assemblies, some food preparation processes, etc. Long-linked technologies require high levels of coordination between tasks to be efficient. Long-Linked Technology II In long-linked technology procedures to complete a unit of work are highly uniform and must be performed in a specified serial order. Organizations based upon long-linked technology generally achieve coordination through planning (scheduling) and typically seek to offset significant environmental uncertainty through vertical integration. Reciprocal Interdependence Reciprocal interdependence is the highest level of interdependence. Reciprocal interdependence exits when the output of one unit serves as the input for a second unit, and the output of the second unit serves as the input for the first unit. Reciprocal interdependence occurs in organizations with intensive technologies. Intensive Technology Intensive technologies provide a variety of products or services in combination to the client. A new product development company is an example, where design, engineering, manufacturing and marketing all must work combine all their resources to suit a customer’s product needs. Intensive technology, because of its reciprocal interdependencies, requires the highest level of management requirements. Reciprocally interdependent units work together intimately and must be closely coordinated; thus, a horizontal structure is appropriate. Intensive Technology II Intensive technology coordination requires high levels of horizontal communication and adjustment. Managers from multiple departments are often involved in face-toface communication. Intensive technologies secure coordination through mutual adjustment. They generally increase their tolerance for uncertainty by ensuring the availability of a variety of specialized services and skills in order to be prepared for any contingency. Intensive technologies are typically the most expensive to coordinate. STRUCTURAL PRIORITIES Thompson posited a series of propositions regarding the structural priorities necessary to account for the different levels of interdependency among units. 1. Under norms of rationality, organizations group positions minimize coordination costs. 1A. Organizations seek to place reciprocally interdependent positions tangent to one another, in a common group, which is (a) local and (b) conditionally autonomous. Structural Priorities II 1B. In the absence of reciprocal interdependence, organizations subject to rationality norms seek to place sequentially interdependent positions tangent to one another, in a common group which is (a) localized and (b) conditionally autonomous. 1C. In the absence of reciprocal and sequential interdependence, organizations subject to norms of rationality seek to group positions homogeneously to facilitate coordination by standardization. Structural Priorities III 2. When reciprocal interdependence cannot be confined to intra-group activities, organizations subject to rationality norms seek to link the groups involved into a secondorder group, as localized and conditionally autonomous as possible. 3. After grouping units to minimize coordination by mutual adjustment, organizations under rationality norms seek to place sequentially interdependent groups tangent to one another, in a cluster which is localized and conditionally autonomous. Structural Priorities IV 4. After grouping units to solve problems of reciprocal and sequential interdependence, organizations under norms of rationality seek to cluster groups into homogeneous units to facilitate coordination by standardization. 4A. When higher-priority coordination requirements prevent the clustering of similar positions or groups, organizations seek to blanket homogeneous positions under rules which cut across group boundaries, and to blanket similar groups under rules which cross divisional lines. Structural Priorities V 4B. When organizations employ standardization, which cuts across multiple groups, they also develop liaison positions linking the several groups and the rule-making agency. 4C. Organizations with sequential interdependence not contained by departmentalization rely on committees to accomplish the remaining coordination. 4D. Organizations with reciprocal interdependence not contained by departmentalization rely on task-force or project groups to accomplish the remaining coordination. Summary of Structural Priorities 1. Reciprocal relationships are the highest level of interdependence, and should receive first priority by being grouped close together in the organization so managers have easy access to one another for mutual adjustment. These units should report to the same person and should be physically close to minimize time and effort in coordination. When such units cannot be located close together, the organization should design coordination mechanisms, such as cross-functional teams, project teams or intranets to facilitate required coordination. Summary, cont’d 2. The next priority is given to sequentially interdependent units or tasks. Once reciprocal relationships are taken care of, or not present, sequentially interdependent units or tasks should be grouped together under a common superior, and as physically close to one another as possible. If a common superior, or physical proximity, is not possible the interdependence should be coordinated through committees or task-forces. Summary, cont’d 3. The final priority should be given to pooled interdependencies. If the interdependence cannot be handled by forming homogeneous groups under a common superior or close physical proximity, standardization across units should be implemented with liaison individuals to handle required crosscommunication between the units. Comparing Technology Contributor Technology Routine Non-Routine Woodward Perrow Mass, Process Routine, Engineering Long-linked, Mediating Thompson Unit Craft, Non-Routine Intensive