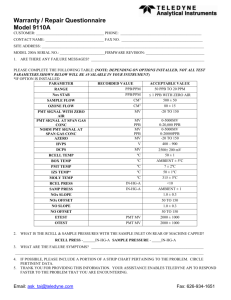

Calibration Considerations

advertisement

Calibration Considerations Using Atomic Spectroscopy “We’re not exactly rocket scientists” And, luckily we don’t have to be. Page 2 Why do we Calibrate? Direct vs. Indirect Methods Direct Measurement Method: • The Measurement of a Physical Property. • Instruments rarely need to be calibrated. • Examples: Weight and Volume Measurements. Relative Measurement Method: • Using an instrument which requires calibration prior to the measurement. • Many Dynamic System Variables • Examples: AAS, Quantitative ICP-OES, ICP-MS. Page 3 Accuracy and Precision Accuracy: Usually expressed as error. The difference between a measurement and the True Value is its absolute error (mg/L). • Accuracy can also be expressed as Percent Relative Error. • How much error is in a typical ICP determination? Precision: Simply the degree of reproducibility of a set of replicate measurements. • Precision can expressed by Standard Deviation (SD) or Percent Relative Standard Deviation (%RSD). • What is typical precision for a set of GFAAS replicates? Page 4 Types of Errors Determinate Errors: • Have specific, identifiable, and correctable causes. • Examples: Contaminated Method Blank, Incorrect Standard Concentration. • Usually main source(s) of most error, can be large. Indeterminate Errors: • Random • Frequently from Multiple Sources • Examples: Flicker (Nebulizer) Noise in an ICP, Mechanical Vibrations, Electronic Noise. • Hopefully small in magnitude • Usually determines detection limits Page 5 Sources of Calibration Error 1. Improper Blanks 2. Improperly Prepared Calibration Standards 3. Calibration Curve Algorithm Type 27 Page 6 Blank Control: Do you have a Contamination Problem? If you are reporting negative answers, you could have a contamination problem! Run lots of different blanks and compare results • Different sources of water • Different sources of acids • Different Flasks • Different Analysts Run blanks overnight and check stability • Checks cleanliness of the instrument Page 7 Sources of Contamination Page 8 (Post-sampling) Analytical Containers (Volumetric flasks, pipettes,..) Storage Containers (bottles) Lab Reagents (including lab pure water) Lab Environment (dust) Analyst (yes, you!) Instrumentation (carry-over) Volumetric Flasks … What are they good for? Very Accurate, but do you really need them? They are NOT for storage! They are NOT for digestions! Clean with 10% HNO3 4 hours Rinse with lots of lab pure water Store filled with lab water Rinse out prior to use Do you use graduated Cylinders? Why? You can use 50mL Autosampler Vials for accurate volumetric measurements. Advantage is less potential sample contamination. Page 9 You can do Volumetric measurements with a Balance 1 mL of distilled water weighs 1 gram Minimize the number of container surfaces the sample touches. Page 10 Pipettes Glass Pipettes: Very Accurate, but do you really need them? Use only larger volumes (>10mL). Clean, check delivery. Re-clean Store dry, away from dust Use Pipettors with disposable tips whenever possible Don’t contaminate the tips! Page 11 How clean are your pipettes? 2% Nitric acid run through 5mL pipets and scanned on ICPMS Page 12 Element Conc. ppb Detection limit Element Conc. PPB Detection limit Ag 2.33 0.0088 Mn 1.72 0.012 Al 6.43 0.13 Na 19.1 0.6 Be 2.62 0.007 Ni 0.96 0.18 Bi 1.07 0.0006 Pb 5.4 0.13 Ca 18.8 2.9 Sn 0.55 0.0033 Co 2.02 0.004 Th 0.24 0.0003 Cr 0.91 0.28 Ti 0.56 0.003 Fe 1.62 0.75 Tl 1.53 0.0075 Mg 2.56 0.016 Zn 9 0.4 Impurities in Container Materials Every Standard needs a Container, but Be Careful Material Total PPM Major Impurities Polystyrene-PS 8 4 Na,Ti, Al Teflon-TFE* 24 19 Ca,Pb,Fe,Cu Teflon-FEP* 25 241 K,Ca,Mg Polycarbonate-PC 10 85 Cl,Br,Al Low Density PE-LDPE 18 23 Ca,Cl,K Polypropylene-PP 21 519 Cl,Mg,Ca Polymethyl Pentene-PMP 14 178 Ca,Mg,Zn High Density PE-HDPE 22 654 Ca,Zn,Si Borosilicate Glass 14 497 Si,B,Na *TFE-Tetrafluoroethylene *FEP=FluorinatedEthylenePropylene Page 13 Total No. of Elements Plastic Packaging Container Purity FEP (FLUORINATEDETHYLENEPROPYLENE) PFA (PERFLUOROALKOXY) FLEP (FLUORINATED HIGH-DENSITY POLYETHLYENE) PMP (POLYMETHYLPENTENE) PP (POLYPROPYLENE) HDPE (HIGH-DENSITY POLYETHYLENE) LDPE (LOW-DENSITY POLYETHYLENE) Page 14 Laboratory Pure Water ASTM Type Page 15 I II III IV Total matter (mg/L max.) <0.1 0.1 1 2 Specific Resist. (megohm-cm) 15-18 1 >1.0 0.2 pH NA NA 6.2-7.5 5-8 Min. color retention time of KMnO4 mins 60 60 10 10 Soluble Silica ND ND 10ug/l high Bacteria Count 0/ml 0/ml 10/ml 100/ml Laboratory Pure Water The Direct-Q ultrapure water system produces 18.2 Megohm-cm reagent water containing less than 30 ppb Total Organic Carbon directly from potable tap water. The system is ideal for scientists needing 5 to 15 L/day of ultrapure water for the preparation of culture media, buffers, blanks and standard solutions. www.elgalabwater.com/ Page 16 Contaminates in Nitric Acid from Major Suppliers (ppb) Supplier Metals Chlorides Price Baker ACS Reagent 2100 100 $56.90/2.5L ACS NF 1500 100 $57.40/2.5L Trace Metal 1000 80 $66.4/500ml 3 100 $213/500ml 4000 80 $51.14/2.5L ACS NF NA 500 $55.18/2.5L Trace Metal 32 NA $51.4/500ml Optima 3 NA $203/500ml Ultrex Fisher ACS Reagent Page 17 Clean Laboratory • • • • • Page 18 Environment of class 100 (less than 100 particles of 0.3microns per m3) Walls, ceilings and floors sealed and dust free HEPA filters mounted in the ceiling No fuming Acids All work performed under clean hood Airborne Contaminants (ug/g) Page 19 Clean Techniques • • • • No jewelry, cosmetics or lotions Wear gloves, Powder-Free Cover hair and mouth Beware of dust, airborne fallout, cover samples How do you determine if you have a clean lab? By running blanks! http://terrauniversal.com/ http://www.aircleansystems.com/ Page 20 Clean Instruments Check parts of the instrument that contact the sample. AA Instruments Graphite Components • Modified Contact Cylinders: Exhibit less carryover and cross contamination for samples with high dissolved solids content. • UltraClean Graphite Tubes: Deliver exceptionally low levels of residual contamination due to extra high-temperature gas-phase cleaning procedure. Extremely low traces of Na, Ca, Fe, Al, Si, Ti, Cr, Ni. Page 21 Clean Instruments ICP-OES Glass Spray Chambers Quartz Nebulizers Ryton Spray Chambers Teflon(s) Polyethylene Sample Tubes PEEK Alumina Injectors ICP-MS Platinum Cones, Injectors Quartz Spray Chambers Sapphire Injectors Page 22 Primary Calibration Standards – Match to your Task AA Grade • Single Element Accuracy • Stability • Traceability ICP Grade • • • • • • Accuracy Purity Stability Chemical Compatibility Traceability Often You can Choose Acid Matrix Multi Element • Reliable if you need lots of elements • More Expensive Page 23 Page 24 ppb Standard Stability Study http://www.ivstandards.com/tech/reliability/part07.asp A blend of 65 elements from Inorganic Ventures / IV Labs' CMS-SET was prepared at the 0, 2, 10, and 100 ppb concentration level in 1 % (v/v) HNO3 at the start of the study. The set consists of the following; CMS-1 - 10 µg/mL Ce, Dy, Er, Eu, Gd, Ho, La, Lu, Nd, Pr, Sm, Sc, Tb, Th, Tm, U, Yb, Y in 3.5 % HNO3 CMS-2 - 10 µg/mL Au, Ir, Pd, Pt, Re, Rh, Ru, and Te in 3.5 % HCl CMS-3 - 10 µg/mL Ge, Hf, Mo, Nb, Ta, Sn, Ti, W, and Zr in 3.5 % HNO3 tr. HF CMS-4 - 10 µg/mL Sb, As, Ba, Be, Bi, B, Cd, Ga, In, Pb, Se, Tl, and V in 3.5 % HNO3 CMS-5 - 10 µg/mL Ag, Al, Ca, Cs, Cr+3, Co, Cu, Fe, Li, Mg, Mn, Ni, K, Rb, Na, Sr, and Zn in 3.5 % HNO3 The LDPE bottles were acid leached with 1% nitric acid for 59 hours at 60 °C. New blends prepared in the same way were compared to the original preparation at 1, 3, 25, 75, 137, 300, and 375 days. Page 25 Experiment Results Hg was not stable long enough to measure (minutes). Au was the next most unstable element, showing instability at the 2, 20, and 100 ppb levels at 3 days. Pd showed instability only at the 2 and 10 ppb levels at 3 days. Pt and Ta showed instability only at the 2 and 10 ppb levels at 137 days. Ag showed instability only at the 10 and 100 ppb levels at 137 days. Mo, Sn, and Hf showed instability only at the 2 ppb level at 375 days. Ir showed instability only at the 2 ppb level at 300 days. All other elements showed no instability at 2-100 ppb for 375 days, including: Ce, Dy, Er, Eu, Gd, Ho, La, Lu, Nd, Pr, Sm, Sc, Tb, Th, Tm, U, Yb, Y, Re, Rh, Ru, Te, Ge, Nb, Ti, W, Zr, Sb, As, Ba, Be, Bi, B, Cd, Ga, In, Pb, Se, Tl, V, Al, Ca, Cs, Cr+3, Co, Cu, Fe, Li, Mg, Mn, Ni, K, Rb, Na, Sr, and Zn. Paul Gaines, Ph.D. Author of Reliable Measurements and other guides Page 26 How do I know if my Primary Standard is Good? Check against a Second Source or SRM • NIST, NRC Canada, Brammer… Check Characteristic Concentration Flame AAS. • Also can use Sensitivity Check Check Characteristic Mass Graphite Furnace AAS (M0). For ICP and ICP-MS, you can check (count/sec) Intensity History. Page 27 Example Proper Calibration Scheme Find Linear working Range. Find the range of your samples. Page 28 Flame Cu Calibration for Samples in the 25-50 ppb range Calibration not quite good enough. Let’s try something… anything. Must meet 0.995 Law Page 29 Flame Cu Calibration for Samples in the 25-50 ppb range Much better, don’t you think? 0.995 condition satisfied What is a little curve fitting among friends? Page 30 Flame Cu Calibration for Samples in the 25-50 ppb range Oh yes, this is the answer: Linear Fit with much higher standards 0.995 Law more than satisfied, cc=0.997 Problem solved! Or is it? Page 31 Flame Cu Calibration for Samples in the 25-50 ppb range What is wrong with this picture? Page 32 Flame Cu Calibration for Samples in the 25-50 ppb range What is wrong with this picture? Page 33 Flame Cu Calibration for Samples in the 25-50 ppb range Look at the change one remade standard can make Page 34 Calibration Mental Mistakes - Review 1. Choosing a curve algorithm to fit data which you know should be linear. 2. Being a “slave” to arbitrary rules like “c.c. must be > 0.995”. 3. Using standard concentrations which are way too high, way beyond your expected sample range, just to get better c.c. statistics. 4. Being lazy, re- make the standards and /or run a second source standard. Page 35 Example: Lead in Calcium Nutritional Supplements Abstract: ICP-MS Intercalibrated measurements of lead in calcium supplements indicate the importance of rigorous analytical techniques to accurately quantify contaminant exposures in complex matrices. Without such techniques, measurements of lead concentrations in calcium supplements may be either erroneously low, by as much as 50%, or below the detection limit needed for new public health criteria. In this study, we determined the lead content of 136 brands of supplements that were purchased in 1996. The calcium in the products was derived from natural sources (bonemeal, dolomite, or oyster shell) or was synthesized and/or refined (chelated and nonchelated calcium) . The dried products were acid digested and analyzed for lead by high resolution-inductively coupled plasma-mass spectrometry. The method's limit of quantitation averaged 0.06 µg/g, with a coefficient of variation of 1.7% and a 90-100% lead recovery of a bonemeal standard reference material. Two-thirds of those calcium supplements failed to meet the 1999 California criteria for acceptable lead levels (1.5 µg/daily dose of calcium) in consumer products. Environ Health Perspect 108:309-313 (2000) . Page 36 Example: Lead in Calcium Supplements (<1 ug/g Pb) Sample Prep; 0.5g sample to 500 mL with acid dissolution. • • • • Sample prep may contaminate samples low level Pb We will need to accurately measure below 1 ug/L for Pb Check Acid Reagent Blanks Check Method Blanks – acids plus containers Is my instrument clean enough for sub ppb work? • Replace or clean any contaminated parts, like cones, injector, … • Check blanks What is the best primary standard to use? What is Best Calibration Range and Curve Type to use? Is a similar matrix SRM available? Page 37 ICP-MS Calibration for Pb •Simple Linear Calibration up to 1.25 ug/L Pb •Second Source QC at 1ug/L; +/- 10% Page 38 NIST 1486 Bone Meal SRM = 1.335 +/- 0.014 ugPb/g Page 39 Results for Reference Materials NIST 1400 - Bone Ash NIST 1486 - Bone Meal Sample ID SRM 1400 SRM 1486 Measured Conc (g/g) 9.10 0.11 1.207 0.008 NIST Certified Value (g/g) 9.07 0.12 1.335 0.014 10 g/g pre-dissolution spike recovery 106% 101% 5% relative Error from Certified Value Detection Limits for Pb in Calcium Matrix Matrix Type Page 40 Calcium Phosphate MDL =(3)(matrix) Solution Nitric Acid IDL = (3)(1% nitric acid) 0.001 g/L Solid 0.001 g/g 0.005 g/g 0.005 g/L 0.1 g/g Postdissolution spike recovery 109% 99% Results for Calcium Tablets Sample ID Page 41 Mean (ug/g) %RSD (n=3) 0.05ug/g %Spike Recov Tricalcium Phosphate -A 0.105 0.88 99 Tricalcium Phosphate -B 0.108 0.60 92 Calcium Carbonate 0.315 1.03 90 Antacid -A 0.114 2.84 93 Antacid -B 0.259 1.28 106 Data Reporting No analysis is complete until the final results have been correctly calculated and properly reported. The report should give the best values obtained and also indicate the probable accuracy or reliability of the results. A single result can express the degree of uncertainty by the number of Significant Figures. • • Page 42 For Example; A weight given as 0.5 g implies that a rough type of balance was used and that the actual weight is between 0.45 and 0.55 g. Furthermore, any subsequent computation using the 0.5 g weight in the calculation of a final value cannot contain any more than 1 significant figure. Obviously, a calculator or computer cannot improve the precision of the original data! Expression # of Sig. Figs. 5.063 4 3600 2 3.600x103 4 0.00123 3 More Data Reporting Standard Deviation and % Relative Standard Deviation can indicate the reliability of the method of measurement. Example: MEAN (n=3) SD 27.6 ug/L 0.35ug/L %RSD 1.27% QC or SRM Measurement Accuracy is commonly expressed as Percent Recovery rather than Percent Relative Error. Example: MEAN (SD) 19.3 (0.22) ug/L Known QC 20.0 ug/L % Recovery 96.5% %Recovery = 100 – (Known-Measured)/Known *100 Page 43 Useful Sources and Links http://ts.nist.gov/measurementservices/referencematerials/index.cfm Nation Research Council Canada http://www.nrc-cnrc.gc.ca/ BRAMMER http://www.brammerstandard.com/ http://www.standardmethods.org/ American Water Works Asso. http://www.awwa.org/ http://www.astm.org/ http://www.astm.org/cgibin/SoftCart.exe/SNEWS/MA_2008/index.html?L+mystore+eswo6699 http://www.inorganicventures.com/tech/reliability/ http://www.spexcsp.com/ http://www.highpuritystandards.com/ Page 44 Thanks for Your Time ! Page 45