Fruits Value-Addition and Drying to Increase

advertisement

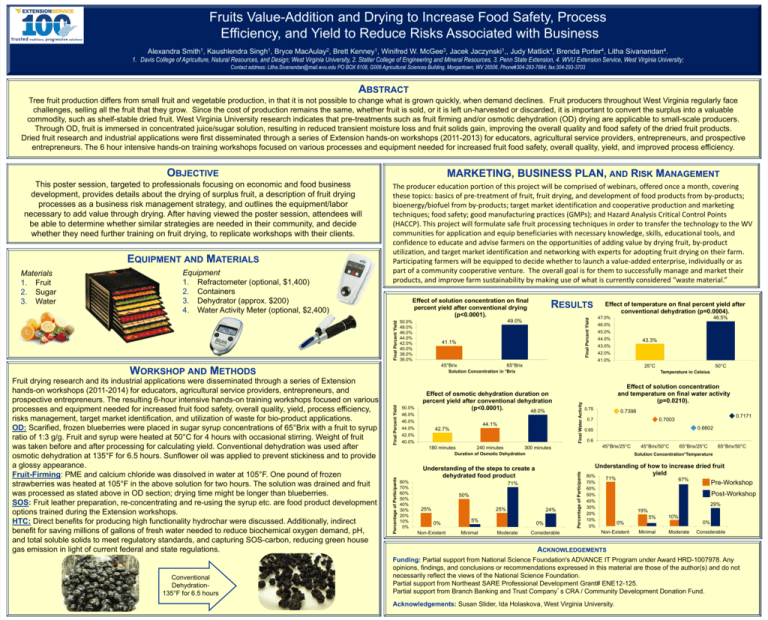

Fruits Value-Addition and Drying to Increase Food Safety, Process Efficiency, and Yield to Reduce Risks Associated with Business Alexandra Smith1, Kaushlendra Singh1, Bryce MacAulay2, Brett Kenney1, Winifred W. McGee3, Jacek Jaczynski1,, Judy Matlick4, Brenda Porter4, Litha Sivanandan4. 1. Davis College of Agriculture, Natural Resources, and Design; West Virginia University, 2. Statler College of Engineering and Mineral Resources, 3. Penn State Extension, 4. WVU Extension Service, West Virginia University; Contact address: Litha.Sivanandan@mail.wvu.edu PO BOX 6108, G006 Agricultural Sciences Building, Morgantown, WV 26506. Phone#304-293-7684; fax:304-293-3703 ABSTRACT Tree fruit production differs from small fruit and vegetable production, in that it is not possible to change what is grown quickly, when demand declines. Fruit producers throughout West Virginia regularly face challenges, selling all the fruit that they grow. Since the cost of production remains the same, whether fruit is sold, or it is left un-harvested or discarded, it is important to convert the surplus into a valuable commodity, such as shelf-stable dried fruit. West Virginia University research indicates that pre-treatments such as fruit firming and/or osmotic dehydration (OD) drying are applicable to small-scale producers. Through OD, fruit is immersed in concentrated juice/sugar solution, resulting in reduced transient moisture loss and fruit solids gain, improving the overall quality and food safety of the dried fruit products. Dried fruit research and industrial applications were first disseminated through a series of Extension hands-on workshops (2011-2013) for educators, agricultural service providers, entrepreneurs, and prospective entrepreneurs. The 6 hour intensive hands-on training workshops focused on various processes and equipment needed for increased fruit food safety, overall quality, yield, and improved process efficiency. OBJECTIVE Effect of solution concentration on final percent yield after conventional drying (p<0.0001). 49.0% 50.0% 48.0% 46.0% 44.0% 42.0% 40.0% 38.0% 36.0% 41.1% Conventional Dehydration135°F for 6.5 hours Effect of temperature on final percent yield after conventional dehydration (p=0.0004). 46.5% 47.0% 46.0% 45.0% 44.0% 43.3% 43.0% 42.0% 41.0% 45°Brix WORKSHOP AND METHODS 65°Brix 25°C Final Percent Yield Solution Concentration in °Brix 50.0% 48.0% 46.0% 44.1% 44.0% 42.7% 42.0% 40.0% 240 minutes Effect of solution concentration and temperature on final water activity (p=0.0210). 0.75 0.7398 0.6602 0.65 0.6 45°Brix/25°C 300 minutes 71% 50% 25% 0% Non-Existent 5% Minimal 24% 0% Moderate 45°Brix/50°C 65°Brix/25°C 65°Brix/50°C Solution Concentration*Temperature Understanding of the steps to create a dehydrated food product 25% 0.7171 0.7003 0.7 Duration of Osmotic Dehydration 80% 70% 60% 50% 40% 30% 20% 10% 0% 50°C Temperature in Celsius Effect of osmotic dehydration duration on percent yield after conventional dehydration (p<0.0001). 48.0% 180 minutes Percentage of Participants Fruit drying research and its industrial applications were disseminated through a series of Extension hands-on workshops (2011-2014) for educators, agricultural service providers, entrepreneurs, and prospective entrepreneurs. The resulting 6-hour intensive hands-on training workshops focused on various processes and equipment needed for increased fruit food safety, overall quality, yield, process efficiency, risks management, target market identification, and utilization of waste for bio-product applications. OD: Scarified, frozen blueberries were placed in sugar syrup concentrations of 65°Brix with a fruit to syrup ratio of 1:3 g/g. Fruit and syrup were heated at 50°C for 4 hours with occasional stirring. Weight of fruit was taken before and after processing for calculating yield. Conventional dehydration was used after osmotic dehydration at 135°F for 6.5 hours. Sunflower oil was applied to prevent stickiness and to provide a glossy appearance. Fruit-Firming: PME and calcium chloride was dissolved in water at 105°F. One pound of frozen strawberries was heated at 105°F in the above solution for two hours. The solution was drained and fruit was processed as stated above in OD section; drying time might be longer than blueberries. SOS: Fruit leather preparation, re-concentrating and re-using the syrup etc. are food product development options trained during the Extension workshops. HTC: Direct benefits for producing high functionality hydrochar were discussed. Additionally, indirect benefit for saving millions of gallons of fresh water needed to reduce biochemical oxygen demand, pH, and total soluble solids to meet regulatory standards, and capturing SOS-carbon, reducing green house gas emission in light of current federal and state regulations. RESULTS Final Percent Yield Equipment 1. Refractometer (optional, $1,400) 2. Containers 3. Dehydrator (approx. $200) 4. Water Activity Meter (optional, $2,400) Final Percent Yield Materials 1. Fruit 2. Sugar 3. Water Final Water Activity EQUIPMENT AND MATERIALS The producer education portion of this project will be comprised of webinars, offered once a month, covering these topics: basics of pre-treatment of fruit, fruit drying, and development of food products from by-products; bioenergy/biofuel from by-products; target market identification and cooperative production and marketing techniques; food safety; good manufacturing practices (GMPs); and Hazard Analysis Critical Control Points (HACCP). This project will formulate safe fruit processing techniques in order to transfer the technology to the WV communities for application and equip beneficiaries with necessary knowledge, skills, educational tools, and confidence to educate and advise farmers on the opportunities of adding value by drying fruit, by-product utilization, and target market identification and networking with experts for adopting fruit drying on their farm. Participating farmers will be equipped to decide whether to launch a value-added enterprise, individually or as part of a community cooperative venture. The overall goal is for them to successfully manage and market their products, and improve farm sustainability by making use of what is currently considered “waste material.” Considerable Percentage of Participants This poster session, targeted to professionals focusing on economic and food business development, provides details about the drying of surplus fruit, a description of fruit drying processes as a business risk management strategy, and outlines the equipment/labor necessary to add value through drying. After having viewed the poster session, attendees will be able to determine whether similar strategies are needed in their community, and decide whether they need further training on fruit drying, to replicate workshops with their clients. MARKETING, BUSINESS PLAN, AND RISK MANAGEMENT Understanding of how to increase dried fruit yield 80% 70% 60% 50% 40% 30% 20% 10% 0% 71% 67% Pre-Workshop Post-Workshop 29% 19% 5% 10% 0% 0% Non-Existent Minimal Moderate Considerable ACKNOWLEDGEMENTS Funding: Partial support from National Science Foundation's ADVANCE IT Program under Award HRD-1007978. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation. Partial support from Northeast SARE Professional Development Grant# ENE12-125. Partial support from Branch Banking and Trust Company’s CRA / Community Development Donation Fund. Acknowledgements: Susan Slider, Ida Holaskova, West Virginia University.