Economic effects caused by the departure of Chrysler

advertisement

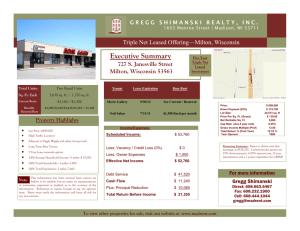

Economic effects caused by the departure of Chrysler from Kenosha, Wisconsin, and General Motors from Flint, Michigan, and Janesville, Wisconsin By Jason Taylor An Undergraduate Thesis Submitted in Partial Fulfillment for the Requirements of Bachelor of Arts in Geography and Earth Science Carthage College Kenosha, WI May 17, 2011 Economic effects caused by the departure of Chrysler from Kenosha, Wisconsin, and General Motors from Flint, Michigan, and Janesville, Wisconsin Jason Taylor Abstract General Motors has a long history in both Janesville, Wisconsin, and Flint, Michigan. Chrysler also has a long history in Kenosha, Wisconsin. These corporations brought large economic growth to these cities, and after their departure they left a major economic void. In 2010 unemployment in Flint is approximately 13%, in Kenosha 11.1%, and in Janesville approximately 13%. Each of these cities have made steps towards redevelopment. Kenosha has been more successful because of its location between Milwaukee and Chicago, and being on Lake Michigan. They have turned the old plant site into an example of urban development by building condominiums, museums, and a marina. Flint has had a long recovery process starting in 1988 and is still trying to find a solution. They have made many attempts including revitalizing the downtown area to increase tourism, and more recently have started to downsize the city. Janesville has just recently lost General Motors (GM) and is still searching for a way to cope. These effects go beyond the economic level and initial job loss. There is broad secondary job loss. As well, the closing of these plants takes a heavy toll on the communities. For example, in Janesville former GM employees are faced with the decision to either go back to school for a new trade, move their whole families, or even commute cross country to other GM plants, which places a lot of stress on family relations. These automotive plants have a large impact on their communities once they pull out, and the recovery process is often decades long. 1 Table of Contents List of Figures 3 List of Tables 3 List of Photos 3 List of Graphs 3 Introduction 4 Background 4 Flint, Michigan 6 Kenosha 10 Janesville 11 Methodology 16 Results 16 Flint 18 Kenosha 24 Janesville 27 Discussion and Conclusions 34 References 38 2 List of Figures Figure 1A, Flint Michigan General Motors Aerial photo 9 Figure 2A, Janesville General Motors Aerial photo 14 Figure 3A, Kenosha Harbor side park Aerial photo 26 Figure 4B, Unemployment by County Group 2010 20 Figure 5B, Genesee County Unemployment by Block Group 2010 21 Figure 6B, Kenosha Unemployment by Block Group 2010 29 Figure 7B, Rock County Unemployment by Block Group 34 List of Tables Table 1, Unemployment Rate for Select Wisconsin Cities 33 List of Photos Photo 1, No Foreign Vehicles 8 Photo 2, The Janesville Assembly Plant 15 Photo 3, Kenosha/Chrysler Plant 25 List of Graphs Graph 1, Unemployment Rate: Flint, Michigan, National 19 Graph 2, Kenosha Unemployment Rate 25 Graph 3, Janesville, Wisconsin Unemployment 33 3 Introduction Living in a community that has grown around the existence of one major industry such as General Motors is like “putting all of your eggs in one basket.” Diversity in investment is a good thing, and relying on just one can have devastating effects when it disappears. This is occurring in many communities that have been home to General Motors (GM) plants. The purpose of this thesis is to explore the broad economic effects that follow the loss of a major manufacturer such as General Motors in Janesville, Wisconsin, within communities and for individuals. These effects include primary job loss and its secondary job loss, and public cost. Public cost includes redevelopment issues, schools, roads and other public infrastructure. The bankruptcy of General Motors is not just a corporate one, but a human one. With this research it will be shown that General Motors leaving Janesville has had a major impact on its economy. This body of research will extend and revise the public knowledge of the closure of General Motors in Janesville. Comparisons will be made between Kenosha, Wisconsin, and Flint, Michigan. Background These communities are now faced with economic devastation from which it could take years to rebound. Losing an automotive plant is just the beginning of a snowballing effect. In Janesville, Wisconsin, the loss of GM was just the first step. Quickly following the announced closure of the plant other companies affiliated with GM, such as Lear 4 Corporation and JATCO started to announce closings (Janesville Gazette Staff, 2008). Other businesses that relied on GM employees have had to lay off their employees or close their doors. High unemployment and lack of other work is forcing these displaced workers to look for employment elsewhere. This in return causes real estate prices to drop due to large numbers of people leaving and high foreclosures. (Dupree, 1973) Retail outlets, day cares, restaurants, medical facilities, banks, and hosts of other businesses are feeling the losses as well. This scenario is being repeated in many communities throughout the country. The effects continue to mount. As of July 2009, the General Motors Fairfax plant in Kansas City, Kansas, has offered 170 positions to senior workers from the former Janesville plant. The program has been set up to provide jobs for laid-off GM workers around the country. While this is good news for the select few chosen workers, this does not solve the greater problem for the whole community. In fact, it is possible that this will take a couple hundred people out of the Janesville area and out of the tax base, which in turn may have effects on all government services. With the departure of these workers, this would also mean a number of houses would go on the market. If the houses do go on the market, the chances of sale are unlikely because of high unemployment and no employment opportunities in the area (Leute, 2009). Rebounding can take years. These communities are now faced with finding ways to bring other industry and jobs into their towns. City and town officials are putting together bids and plans on how to attract new industry and businesses (Janesville Gazette Staff, 2008). Without these they will continue to see a decrease in human 5 population. The bottom line is that many of these communities will never be like they were with the presence of General Motors and other automotive industries. Before analyzing the effects the closing of these plants has had, an in-depth look at the history of automotive companies in these three cities will be taken. Flint, Michigan The Flint Michigan plant was opened on September 11, 1903, under a successful business man Billy Durant. Durant ran what was then a Buick plant under the worst conditions he could find in the Flint area because he was skeptical of the “horseless carriage.” Later convinced that the Buick was a superior car, Durant turned his attention to building automobiles. Buick soon became the nation’s most popular vehicle. Durant established a record unmatched by any individual in the history of the automotive industry. Durant introduced two key concepts that define manufacturing today, customer choice and industry consolidation. In 1908 he founded the General Motors Company, by combining Buick with an assortment of manufacturers and suppliers (Jaeger). The 1930’s witnessed the rise of the United Auto Workers. On the morning of December 30, 1936, workers camped inside GM factories in the nation’s largest “sitdown-strike.” It lasted 44 days and brought GM production to a virtual halt (Jaeger). During World War II, Flint also began arming the nation. Along with other automotive factories they turned out ship instruments, tanks, shells, shot and machine guns. Most noticeably they produced the Hellcat, a fast-moving tank destroyer (Jaeger). 6 Flint boomed in the 1950’s. In 1957, General Motors marked the production of its 50 millionth vehicle. But over time the unpredictable industry fell to foreign competition, lower business costs elsewhere, and the North-American Free Trade Agreement drained many of the jobs from the area. GM’s employment dropped from 82,000 in 1970 to 14,500 today (Jaeger). Harlow Curtice was the last General Motors President to live in the City of Flint. The manufacturing of cars in Flint stopped in 1998 when Buick City was closed. General Motors trucks continued to be produced in Flint along with engines and other auto parts until the Powertrain Flint North plant closed in December 2010 (Roberts, 1999; Burden, 2009) What was once good for General Motors now had become what was bad for America. Over the years, Flint became the quintessential company town. The majority of people worked for GM. Their homes were built by GM construction companies, and GM held the mortgage. People bought their cars from GM and they held the lien on that too. GM took care of their every need. Then GM discovered that they could make cheaper cars in the non-union south. In the 1990’s developing countries became an even better option, and this led to feelings of resentment for GM employees towards foreign-made cars (Photo 1). What GM left behind was thousands of displaced workers, many who left. Much of the downtown has been demolished or boarded up and many of the remaining residents line up weekly for government surplus supplies. The plant sits vacant and in disrepair along with many neighborhoods surrounding the area. (Figure 7 1A) In 1987 Flint was named the second worst city in America to live in. (Moore, 1987 753) Photo 1, No Foreign Vehicles (Jason Taylor) When the General Motors Plant in Flint shut down approximately thirty thousand workers lost their jobs. More than half of Flint’s residents became unemployed. Flint became the most poverty stricken city in the United States. In 1960 there were approximately 28 spinoff operations in Flint that were affiliated with the automotive industry. Of the 80,000 workers in Flint during General Motors peak years in the 1970’s, only about 8,000 remained as of 2006. Many residents have moved to Wyoming to seek employment in the booming coal, oil, and gas industry. (“Flint, Michigan”) 8 9 Kenosha Kenosha’s Chrysler automobile industry was much like Janesville’s. It began in 1902 with Nash Motors, and grew into the world’s largest truck manufacturer by 1918. Nash joined with Kelvinator, an appliance producer, in 1936, creating Nash-Kelvinator. That company built cars until World War II, when it switched to producing combat aircraft engines and propellers. When the war ended, car production resumed. In 1954 the company merged with Hudson, creating American Motors Corp (AMC). AMC employment peaked at 17,000 in the 1960’s. But by 1974 the numbers fell below 13,000 and steadily declined after that. Faced with financial problems they merged with Renault, a French auto maker in 1979. Renault sold to Chrysler in 1987 (Content, 2009). The new owners felt that the Kenosha plant was inefficient and the company had other car production plans. In January of 1988 the closure of the Chrysler plant was announced. The last car was built in Kenosha, an Omni/Horizon, on Dec. 21, 1988. Some 11 million cars had come out of the Kenosha’s car factory by then. The abandoned Chrysler plant was torn down by 1990 (Content, 2009). Kenosha’s relationship with its carmakers from AMC’s beginnings through the Chrysler purchase has been stormy. Always there was the hope that somehow the small US auto market could make and market a car line distinctive enough to compete against the Big Three of Chrysler, Ford and General Motors. (Sussman, 1988) 10 On Friday October 22, 2010 the last engine scheduled for production at the Chrysler plant in Kenosha rolled off the assembly line. This left behind the same unanswered questions for this plant and its future. Like other cities facing the loss of these plants, taxpayers could be confronted with the cost to environmentally clean up the facility before it could be reused. Current plans for the site are to continue to market the facility for a few years. If this doesn’t work then the site could be cleaned up and turned into a green space. For the remaining 500 employees this means retiring or relocating to other plants in Illinois and Michigan. It’s another sign of the end of an era for Wisconsin. (Taschler and Barrett, 2010) Janesville In 1918 Joseph A. Craig brought GM’s Samson Tractor to Janesville, Wisconsin and merged it with Janesville Machine Co., a maker of farm implements and employer of 300 workers. Its first Model M tractor was produced on May 1, 1919 in a one story factory. In just 18 months Janesville’s population grew from 14,000 to 20,000 as people moved in to work in the tractor factory. The tractor factory employed 3,000 people by 1919. Since its beginning GM in Janesville brought a boom to the city (Janesville Gazette Staff, 2008). In 1921 tractor production in Janesville slowed almost to a halt because of the national farm depression. It was shortly after this that Chevrolet announced its plans to purchase the plant and add a Fisher Body plant. Janesville’s first Chevy was produced 11 on April 1, 1926, with a daily quota of 380 cars a day or 10,000 a month. Just four months later, the local plant produced its 500,000 car (Janesville Gazette Staff, 2008). The great depression hit Rock County in the early 1930s, causing frequent shut downs and layoffs. During this time the union movement was resurrected and Janesville’s autoworkers played a key role in forcing GM to recognize the United Auto Workers. By 1934 GM began to rebound with a work force of nearly 3,000 (Janesville Gazette Staff, 2008). In the 1940’s the production lines in Janesville joined the rest of the United States in its World War II effort. It began producing approximately 16 million artillery shells in three years. In August 1945 all military contracts were canceled and GM plants returned to Chevrolet and Fisher Body Control (Janesville Gazette Staff, 2008). In the 1950’s, due to GM, Janesville experienced tremendous growth in business, housing, population and its general sense of community. GM’s Fisher Body added a second shift and the Chevrolet division followed shortly. A year later, the Chevy plant produced its 3 millionth vehicle and its workforce reached the 4,000 mark. By 1955 the workforce had swelled to 4,900(Janesville Gazette Staff, 2008). The 1950’s showed many ups and downs for the local plant, but by 1968 it had several milestones. Hourly and salaried employment increased from 5,700 to nearly 7,000. They also turned over their 100 millionth vehicle (Dupree, 1973). The 1970’s and 1980’s again had their ups and downs with several periods of layoffs. In the eighties, a lack of interest in large gas guzzling cars forced GM to change 12 their line to smaller, more fuel-efficient, front-wheel-drive J-cars. In 1984 GM moved its truck line to Fort Wayne, Indiana. Local and state officials scrambled to get the truck line back. In 1989 a small line of medium duty trucks was produced at the Janesville plant. By the end of the 1980’s GM in Janesville ended up with 1,400 fewer jobs and were looking at how to have a better chance for long term survival (Janesville Gazette Staff, 2008). GM steamrolled through the 1990’s thanks to the groundwork laid in the 1980’s. With the production of the Suburban, Chevy Blazer, GMC Jimmy, and hot selling SUVs, which were back ordered up to six months, the local plant continued to succeed. As the nineties ended, the Janesville plant was assured many years of work - at least through 2005, on the SUV line (Janesville Gazette Staff, 2008). In 2000 the outlook was still positive for the plant, but rumors were beginning to surface about its future. Janesville dodged GM’s reduction in November 2005, but poor sales of big trucks continued to plague the plant. But the end was near, and on December 23rd, 2008, the Janesville plant ended production forever. The now empty G.M. plant sits vacant and awaiting it’s unknown future (Photo 2; Figure 2A) All arbitration efforts and state and local government efforts couldn’t stave off the closure and the bankruptcy of General Motors (Janesville Gazette Staff, 2008). The effects of the closing of General Motors on December 23, 2008, were no surprise to many in the community, including John Resch, a retired General Motors worker, who visited Flint, Michigan, in the late eighties. He noticed the devastation of 13 14 Photo 2: The Janesville Assembly Plant (Jason Taylor) the entire community with “block after block after block, businesses completely shut down” (Vogel and Ames, 2008 14A). Knowing how this affected Flint, it did not seem to bode well for Janesville. While all of the General Motors plant closings were different, they were similar in how they can devastate a whole community. With General Motors recently filing for bankruptcy, the Federal government in early summer 2009 took ownership of the plant and decided to re-open one of the plants. Janesville and the plants in Spring Hill, Tennessee, and Orion, Michigan, were the top three choices for a new small-car plant. While this could bring hope to shattered communities, it may be unwise to rely on this kind of hope. It is possible that moving on to other reconstruction acts would be better than waiting for something that may never come. 15 Beyond the local level, General Motors’ bankruptcy and the closure of its plants has started to affect buyers’ choices and questions as they shop for cars. Consumers are a little more cautious about buying GM vehicles with news of the company’s bankruptcy. While these extra worries may be unwarranted, they still have an effect on the economy on the local and national level (Associated Press, 2009). Methodology Through the program Business Analyst unemployment data was extracted. With this data set, the effects General Motors has had in Flint Michigan, Janesville Wisconsin, and Chrysler in Kenosha Wisconsin, can be shown. The use of Arc map GIS will map this data. Further research was obtained through the use of outside sources such as internet resources, books, historical documents from the Janesville Public Library, newspaper articles, scholarly articles, and film documentaries. Excel was used to plot a unemployment graph for Kenosha, Wisconsin. Results Although these three areas will not become ghost towns it will take a great deal of time to rebuild hard hit local economies. Displaced workers who were not lucky enough to transfer to another plant face lengthy unemployment and re-education costs. Many displaced workers have chosen to move on with their lives and not take a passive attitude about their future. 16 Finding uses for abandoned auto plants is another major problem communities face. Of the 128 manufacturing plants in North America closed since 1980 by the Detroit Three automakers and their largest suppliers, three of every five are still idle. At their peak of economic activity hundreds of thousands of people, mostly well-paid union members on the assembly line and white-collar engineers in offices above the factory floor were employed. These 128 plants had a payroll of 196,000 workers. Today only 36,500 people work at those sites that have been redeveloped, and at only three of the revived plants does the number of employees match or exceed the number in their car making past. The rest are concrete prairies or steel monstrosities waiting for reuse or a wrecking ball. Most haven’t any real prospects for re-use in the future. The cost of these vacant factories will be carried over to the next generation and beyond. (Janesville Gazette Staff, 2010) In the past when a factory closed many workers just moved to a new plant nearby. But today with the sharp cutbacks in the auto industry these jobs will never return. These are permanent closures that aren’t going to be replaced. Two decades ago General Motors employed as many as 20,000 workers inside a two-mile radius around the Detroit suburb of Pontiac. In the fall of 2009, of a plant that made Chevrolet Silverado and GMC Sierra trucks closed, the last of those jobs vanished. This causes very little real estate interest, and makes re-development difficult. The loss to surrounding businesses could be as high as 50%. For example, the owner of a bar across from the closed Pontiac plant lost 60% of his sales from the previous three 17 years. The owner holds little hope of any new business bringing him back to where he was. (Janesville Gazette Staff, 2010) The cost of re-developing these factories is huge. It would take a large investment to get them back into productive use. The obstacles are many: a large number of these plants are far from urban centers, and nearly all have paint, waste, heavy metals or other hazardous materials on site. Many of these exceed regulatory limits and cleaning up those toxins can cost as much as $300,000 an acre and take years. Flint For Flint the recovery process has been slow and painful. Many proposals have over the years helped slow the decline but none have helped to speed up the recovery. Instead of waiting for houses to become abandoned and then pulling them down, local leaders are talking about demolishing entire blocks and even whole neighborhoods. (Gray and Okrent, 2010) In the 1989 documentary Roger & Me, Michael Moore recounts the lack luster attempts the city of Flint has made towards recovery after the departure of GM. The city of Flint tried to build a tourism industry by opening a shopping center, a luxury Hyatt Regency hotel, and AutoWorld theme park and museum, all of which were closed within a year. The film presented the attitudes of the richer residents of Flint and some of the GM officials who thought most of the former GM employees were lazy in their search for a new job. The reality of their situation was grim; they faced evictions and were often 18 forced to take jobs at fast food restaurants or take jobs in door-to-door and out-of-home sales. At one point the rat population exceeded the human population in Flint because of all of the abandoned homes and poor sanitation due to budget cuts. Moore portrayed the GM officials as being unsympathetic to the people of Flint and being more concerned about the health of their business than their former employees. The recession in Flint, as in many old-line manufacturing cities, is making an already bad situation worse. City employees such as police officers and firefighters are being laid off due to the huge city deficit. Many public schools are being closed or have closed already (Gray and Okrent, 2010). As of 2010 the average national unemployment rate was 9.6%. For Michigan as a whole it was 12.8%, and Flint was at 13.0%. (Graph 1) (Figure 4B and Figure 5B) Graph 1, Unemployment Rate: Flint, Michigan, National (Department of Numbers 2011) Flint unemployment makes a large increase in 1998 when the GM plant closes. With this spike it raises well above the national average at the time, and also the Michigan average. While the rate for Flint follows the general movement of the national and state unemployment rates it tends to fluctuate much more. This graph may reflect the layoffs and other changes that took place at GM. ____ Flint ____ Michigan ____ National 19 20 21 One way Flint is searching for a way out is by a planned shrinkage program of its city. Planned shrinkage became a feasible idea in Michigan a few years ago when state laws changed regarding properties foreclosed for delinquent taxes. Before this change most abandoned properties were tied up in legal limbo just contributing to the problem. Now they can quickly become property of the county land banks, giving communities a powerful tool to change things. (Gray and Okrent, 2010) Right now Flint’s population is 110,000, and about a third of these people are unemployed and live in poverty. Flint has about 75 neighborhoods spread out over 34 square miles. It will be a tough process to decide which neighborhoods to save and which ones to tear down. In the last year the county has acquired about 900 homes, some from healthy neighborhoods. By downsizing, Flint will renew some areas of town and demolish others. This decision was not easy but Flint has to move ahead and face the reality of the current situation (Gray and Okrent, 2010). In July of 2009 Dan Kildee, the treasurer of Genesee County commented that, “There’s an obsession with growth and expansion. I’m not against growth. But what we really have to do is recognize that the city has already shrunk, and because we’re not growing does not mean we can’t be a good city.” (Brooks, 2009) A movement in which he believes strongly is “going green.” Flint needs to look at the design of the city block by block and decide what to let nature take back and where to create some intentional open and green space so that the 100,000 residents can live in a city that doesn’t look half deserted (Brooks, 2009). This would save money on city 22 services like fire, police and sewer and focus limited city resources and investment in neighborhoods that are more viable. Almost a quarter of the city could be bulldozed or transformed into green space. In fact, this has already begun. (Brooks, 2009) In one neighborhood on Flint’s east side a community garden has been planted where five homes used to stand. This provides free fruits and vegetables to this part of the city. What was once a virtual wasteland is now providing food for residents and is a factor in community development (Brooks, 2009). This is a small step but not a viable solution for everyone. For those who are still living in homes that they built to raise their families, there is much fear and uncertainty of what will happen to them. Many homes in neighborhoods are no longer fit for habitation and need to be demolished. But that doesn’t mean that other residents want to lose their homes. There are two options here, one would be to give these neighborhoods a green makeover so that residents have a decent area to live in, or offer them the opportunity to move to more high density, higher-functioning areas. (Brooks, 2009) By going smaller and greener Flint could be a stronger Flint, but cost issues and political challenges exist. Flint is recovering in a culture that is based on economic expansion and growth; proponents of shrinking cities have to make a case that shrinking the city is not giving up but that by making Flint smaller it could be a better city. (Brooks, 2009) 23 Kenosha Chrysler in Kenosha, Wisconsin closed an engine plant which put 850 people out of work in 2010. Back in 1988, the company cut 5,500 jobs by closing a plant along the lake shore. Below is a graph showing the unemployment rate for Kenosha from 1990 through 2011. The city spent $50 million to demolish an old building along Lake Michigan, clean up environmental problems and build streets. At one time Harbor Park in Kenosha was the fenced in ruins of an abandoned auto plant. The photo below (Photo 3) shows the Kenosha plant during the mid-sixties while still in operation (Ziemnowicz, 2004). Abandoned in the 1990’s Kenosha took almost a decade to renew the abandoned site. Now, an impressive collection of more than 350 upscale condominiums, two museums, walkways, parks and a marina have been built on Kenosha’ lakefront, Harbor Park has become an example of urban and industrial renewal for Kenosha (Figure 3A). Although technically a success, fewer than 100 people now work there, most of them behind cash registers or waiting tables (Janesville Gazette Staff, 2010). Along with the revitalization of the lakefront, downtown area has also seen improvement. The loss of the automobile industry gave Kenosha a chance to redevelop its city and Kenosha chose to do just that. (Brooks, 2005) Even three years after Chrysler closed more people believed that Kenosha had become a better place than before the closing of the plant. In 1991, 26% of a surveyed group of Kenosha residents found it a very desirable place to live compared to 18.4% in 24 Graph 2, Kenosha Unemployment Rate (U.S. Department of Labor: Bureau of Labor Statistics, 2011) Photo 3: Kenosha/Chrysler Plant (Ziemnowicz, 2004) 25 26 1987. This is because the economy had become diversified with 4,000 non-auto industry related jobs, and because more Illinois residents moved to Kenosha looking for lower cost housing (Moran, 1991). Moran (1991) cites Kenosha News (1989) that in 1989 Kenosha annexed 1,500 acres from the Town of Pleasant Prairie to the city. With the increased revenue from taxes earned from this annexation, Kenosha was able to pay for the improvements to Lakeview Corporate Park. In the same year, Governor Thompson backed the $2 million state grant, which helped with the city’s recovery plans (Moran, 1991). The newly developed harbor has become a haven for Milwaukee and Chicago commuters looking for affordable lakefront property. Harbor Park condominiums are seeing a 15 to 10 % appreciation annually. Two to three years ago you could purchase a condominium for around $100,000, now they sell between $200,000, for a small unit, and for a larger unit $700,000. (Brooks, 2005) Due to the proximity to Harbor Park the downtown has seen expansion including the opening of several new restaurants, clothing stores, a wine bar, and shops. Further development is planned with the building of a nine story condominium tower and a 60room hotel. Special events such as the tall ships festival, a 2006 country music festival, an outdoor marketplace, the Kenosha Public Museum, located just east of the parkway, and the Civil War Museum all help to revitalize this abandoned automobile plant site. (Brooks, 2005) 27 As of 2010 Kenosha County’s population is 162,921 and has seen a population growth of 8.31%. As of 2010 unemployment in Kenosha County is 11.1 % with a U.S. average of 9.7% (Figure 6B). Recent job growth is negative and Kenosha jobs have decreased by 0.80%. But from the bleak past with the loss of the automobile industry Kenosha has taken strides forward in rebuilding and growth. Janesville One year after General Motors shut down in Janesville vacant homes and for sale signs line the streets. The Lear Corporation that once built seats for General Motors and GM Plant that was once the heart of the community now sit vacant. For residents of the Janesville community it has been a year of tough times and hard choices. Trying to find jobs and finding none locally is depressing and frustrating for many in the community. Some residents have taken transfers to GM plants in Kansas and Texas, forcing them to move and in some cases face long commutes and time away from family and friends. Some have returned to school to learn new trades and embark on new careers. (Glauber, 2009) Many remain optimistic about the future and feel that the community will persevere. Right now in the early stages and still reeling from the loss Janesville is still looking for a way to lure the thousands of jobs needed in a post-GM community. Few believe that vehicles will ever roll off the assembly line in Janesville again. (Glauber, 2009) 28 29 Others have chosen instead to learn a new trade. In Janesville, former autoworkers have prompted record enrollments at Blackhawk Technical College and UW-Rock County. For example, a former Lear employee is working towards a degree in supply chain management at UW-Rock County, and a former GM employee is working towards a diploma in industrial management at Blackhawk Technical Institute. These are just a couple of examples of how displaced workers are taking charge of their futures. As with any disaster, these displaced workers are working to rebuild their families’ lives and their communities (Janesville Gazette Staff, 2009). The other side is for those workers who took transfers to other plants in Kansas City, and Arlington, Texas. Many of these workers have left their families behind and commute home on weekends. Although this is difficult on families, some consider it better than being unemployed. Al Hammer is grateful to have a job after the GM plant in Janesville closed but struggles to say goodbye to his family when he leaves for Kansas City each week. Hammer spends hours on the road commuting 530 miles one way, a lot of money on gas and oil changes, but the hardest part is saying good-bye to his 11-year old daughter. It’s a difficult change in his life but he needs to go where the money is. (Spicuzza, 2009) Over 500 former GM workers from the Janesville plant have transferred to other company locations around the country. Some have sold their homes and relocated, while others have chosen not to uproot their families and are trying to manage long distance marriage and family relations. These separations could last for years while 30 families wait for children to graduate from school, a family home is sold, or a spouse can retire. (Spicuzza, 2009) Despite the separation, families are happy that loved-ones have jobs. More than 1,200 people lost their jobs when GM closed the 90-year old Janesville plant and after the closing of related supplier companies. Unemployment in Janesville has climbed to 10.9 percent, the highest of all metro areas in the state, making the chance of finding local jobs bleak. (Spicuzza, 2009) For about every 4,500 GM and auto supplier jobs that disappeared, another was lost outside the industry. The ripple effect has been enormous. About 9,000 of the county’s 75,000 jobs vanished. (Janesville Gazette Staff, 2010) Bob Borremans, is the executive director of the Southwest Wisconsin Workforce Development Board. He gives a four step economic outlook for a community after a major plant closes. The first is the closing of the facility, then the loss and end of benefits. For Janesville this started with the slowdown of production at the General Motors Plant, which then triggered the layoffs of more than 3,000 workers in the local auto-manufacturing sector. Workers at GM and their supplier companies Lear Corporation and LSI happened in three waves. First GM shut down, then Lear Corp., and finally LSI. Then this was followed by the consolidation and loss of a smaller supply market, and the eventual collapse of the local real estate market. When the benefits run out is when the really high stress levels kick in. The loss of a major business is a form of economic death. The community will go through a seven-step grief process just as if 31 facing a death of a friend or family member. It starts with the shock and progresses through the denial, anger, bargaining, depression, testing, and acceptance. (Janesville Gazette Staff, 2009) According to the Department of Workforce Development, Janesville’s unemployment rate as of April 2009 was 12.9%, the highest in the state at the time (Table 1). 2010 unemployment for Rock County is still holding steady between 12.7% and 17.1% (Graph 2). Unemployment for 2010 in (Figure 7B) shows Rock County broken down by block groups. A block group is the percentages of unemployment per area by population. A city that once flourished now has many citizens standing in food lines run by ECHO that has never seen this much need in its 35 years of operation. Many believe the worst has yet to come. Once unemployment benefits run out things will get harder for displaced workers. (Glauber, 2009) Rumors were around for years that General Motors would close in Janesville but many still held hope for its continued survival. Now in the early stages and still trying to accept the fact that GM is gone many still wonder where Janesville will go from here: a new future and development without GM or a downsizing, like Flint is experiencing. While the displaced workers have moved on in the two years since the plant closed its operations in Janesville, the plant sits eerily idle with no immediate future plans. GM did retain this plant in its bankruptcy under the category of a standby plant if the automaker needed more space to build cars and trucks. Not much can be done with 32 Table 1, Unemployment rate for select Wisconsin Cities (Department of Workforce Development, State of Wisconsin, 2009) Metropolitan Statistical Area Wisconsin Appleton Eau Claire Fond du Lac Green Bay Janesville La Crosse Madison Milwaukee-Waukesha-West Allis Oshkosh-Neenah Racine Sheboygan Wausau April 2009 March 2009 April 2008 8.8% 8.6% 7.4% 9.0% 8.4% 12.9% 6.8% 6.0% 8.9% 9.4% 9.4% 8.7% 10.1% 9.2% 13.6% 7.7% 6.5% 9.0% 4.2% 4.0% 4.1% 4.0% 4.0% 4.8% 3.4% 3.0% 4.0% 8.1% 10.6% 9.2% 9.0% 8.4% 10.7% 9.9% 9.4% 3.8% 5.0% 3.6% 4.1% Graph 2, Janesville, Wisconsin Unemployment (Department of Numbers, 2011) The graph below demonstrates how much the unemployment rate fluctuates in Janesville compared to the changing, but still relatively stable state and national level rates. In the late 2008 to early 2009, there are steep increases in unemployment at all three levels, but again Janesville appears more affected by both the loss of General Motors and the national economy. ____ Janesville ____ Wisconsin ____ National 33 34 the plant until GM decides whether or not they need it. There are two possible scenarios for the future of the Janesville plant. One would be some sort of GM production. Unfortunately for Janesville, GM is more likely to use Michigan where tax incentives are being offered that Janesville can’t match. The other would be if GM decides it no longer needs the plant and agree to either sell it or donate the property to the community or a third party developer. Whatever happens, Janesville has to look to the future and what is best for its community. Discussion and Conclusions Cities build their communities with population growth that is encouraged by local job opportunities. Those communities that are built primarily around one industry such as the automotive industry can have great growth and prosperity but are also can be faced with great challenges when that industry experiences losses or departs. Janesville, Wisconsin, Flint, Michigan, and Kenosha, Wisconsin, are examples of the challenges faced with the loss of the automotive industry in their communities. These three communities along with many others in the United States put a great deal of faith in the stability of these companies and what they promised to their cities growth and prosperity. Betrayal and shock are now what most displaced workers express when asked how they feel about the closings. Many just thought it would never happen in their towns. After the shock these areas now have to come up with solutions to their survival. 35 For Flint Michigan, the inability to draw other major industry and jobs needed for displaced workers have forced them to downsize the city itself. Realizing that Flint will not return to its automotive industry days it is working to salvage what is left of its community and revitalize what remains. Kenosha has been rebuilding and revitalizing the lakefront that once held the Chrysler plant. Harbor Park has brought about re-growth of the downtown, increased property values, and added needed jobs. While Flint has been forced to make the city smaller by condensing the city Kenosha has torn down the old Chrysler plant and brought in new condominiums, a beautiful park, marina, museum, and housing, and has annexed area from a neighboring town. With the given location right on the lakefront and help from a state grant, Kenosha had the opportunity to redesign and refocus on a new future. For Janesville, the steps that need to be taken towards economic and community development remain undecided. Recent into its loss of General Motors there is still much to be done. Economic development for Janesville like Flint, and Kenosha will be an ongoing process. Janesville does not have enough jobs to accommodate all the displaced workers, especially with high paying jobs. Encouraging new industry into the community will be essential to Janesville’s recovery. Unfortunately this is not a problem to be solved overnight and many displaced workers are now faced with loss of benefits and unemployment payments, which will only add to the already struggling economy. 36 Diversity is a good thing in any investment and is essential when building a city and community. It is not wise to put an entire savings in one piece of stock because when that stock value drops, there is little or no investment left. That is what is happening on a much larger and more devastating scale in Janesville. So much was invested in General Motors, the city now has to accept its losses and decide how to start over and move forward to ensure the success of its community. This is not only true for the city itself but for the thousands of displaced workers and their families which now face uncertain futures as well. If time were to allow, further research would be directed towards how the cities grew up around these automotive corporations in the first place and how secondary companies are affected. For example, the fast-food industry focuses on these cities and attracts plant employees by having extended operational hours. 37 References Associated Press. 2009. “GM’s fate slows buyers.” The Janesville Gazette. June 1, sec. A. Associated Press. 2010. Wixom Michigan-Detroit. “Cities Struggle to find uses for auto plants.” The Janesville Gazette, Sec. B. Brooks, Anthony. 2009. “Flint Michigan: Growing Stronger by Growing Smaller?” National Public Radio, July 13. <http://www.npr.org/templates/story/story.php?storyId=106492824 > Brooks, Erik. 2005. “HarborPark condos spark renewal of Kenosha lakefront.” The Business Journal of Milwaukee, June 17. <http://trolleydogs.com/article.aspx> Burden, Melissa. 2009. “General Motors Powertrain Flint North workers learn their plant will close in December 2010.” Flint Journal. 1 July 2009. <http://blog.mlive.com/genesee-generalmotors/2009/06/general_motors_powetrain_flint.html> Content, Thomas. 2009. “Chrysler won’t keep Kenosha engine plant.” Journal Sentinel. May 1. <http://www.jsonline.com/business/44162607.html> Department of Numbers. 2011. “Flint, Michigan Unemployment.” <http://www.deptofnumbers.com/unemployment/michigan/flint/> 38 Department of Numbers. 2011. “Janesville, Wisconsin Unemployment.” <http://www.deptofnumbers.com/unemployment/wisconsin/janesville/> Department of Workforce Development, State of Wisconsin. 2009. “April Local Unemployment Rates Announced.” <http://dwd.wisconsin.gov/dwd/newsreleases/2009/unemployment/0409_local_lm i.pdf> Department of Workforce and Development, State of Wisconsin. 2011. “FEBRUARY LOCAL UNEMPLOYMENT, JOB NUMBERS ANNOUNCED.” http://dwd.wisconsin.gov/dwd/newsreleases/ui_local_default.pdf Dupree, Mike. 1973. “G.M., Janesville Grow Together.” Janesville Gazette. June 2. Glauber, Bill. 2009. “A year after GM plant closure, Janesville stays afloat however it can.” Journal Sentinel, Dec. 13. <http:www.jsonline.com/news/Wisconsin/79145747.html> Gray, Steven and Daniel Okrent. 2010. “The Future of Detroit: How to Shrink a City.” Time. 40-47. Gustin, Lawrence R. 2008. “GM and Flint Grew Up Together.” Automotive News, Sept. 15, Vol. 83 Issue 63Z, 93-93 Jaeger, Sally. “History.” Date not available. <http://www.flintgm100.com/history.html> 39 Janesville Gazette Staff. 2008. “Through the Years.” Janesville Gazette, Dec. 22. >http://gazettextra.com/news/2008/dec/22/through-years-chronicling-history-gmjanesville/ > Janesville Gazette Staff. 2009. “Former autoworkers steering their lives in positive directions.” Janesville Gazette, Dec. 26, sec. A. Janesville Gazette Staff. 2009. “Running on Fumes: City braces for impact when benefits run out.” Janesville Gazette, Dec. 20, sec. A. Janesville Gazette Staff. 2010. “Job with a catch: A 1,000-mile commute.” Janesville Gazette, Feb. 22, sec. A. Leute, Jim. 2009. “170 more could be gone.” Janesville Gazette, July 15, sec. A. Moore, Michael. 1987. "In Flint, Tough Times Last." Nation 244, no. 22: 753-756. Moran, Patrick E. 1991. “Kenosha City of the Grow.” Master’s Thesis, Carthage College. Sussman,Lawrence. l988. “Cars without a market drove Kenosha plant to oblivion.” Milwaukee Journal, Jan. 27. “Flint, Michigan.” Flint Tree Services. <http://flinttreeservices.com/city_info.html> Roberts, Larry. 1999. “General Motors closes Buick City Complex in Flint Michigan.” World Socialist Website, July 2, <http://www.wsws.org/articles/1999/jul1999/autoj02.shtml> Roger & Me. 1989. Directed by Michael Moore. Warner Bros, DVD. 40 Sperlinlg’s Best Places. Kenosha County, Wisconsin. http://www.bestplaces.net/county/kenosha-wisconsin.aspx Spicuzza, Mary. 2009 “Job transfers strain family ties for former Janesville GM workers.” Wisconsin State Journal, Dec. 28, sec. A. Taschler, Joe and Rick Barrett. 2010. “End of the line for Chrysler Plant.” Janesville Gazette, Oct. 23, sec. A. Vogel, Stacy, and Ann Marie Ames. 2008. “Despite rumors, plant closing comes as a shock to workers.” Janesville Gazette, June 4, 2008, sec. A. Ziemnowicz, Christopher. 2004. “Corporate Strategy at AMC at Time of the Marlin: a short review from George Romney to Roy Chapin, Jr.” <http://academics.concord.edu/chrisz/hobby/67-Marlinitems/HistoryFaces/MarlinStory.html> U.S. Department of Labor: Bureau of Labor Statistics. 2011. “Unemployment Rate in Kenosha County, WI.” <http://research.stlouisfed.org/fred2/data/WIKENO9URN.txt> 41 42