01-acetoneconverison-setiadi-sntki-plmbang

advertisement

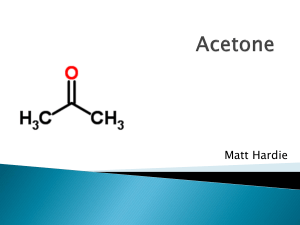

Makalah (Code KKR 09) Time on Stream Stability of H-ZSM-5 Catalyst on Acetone Conversion to Aromatic Chemicals Disampaikan dalam Forum Seminar Nasional Teknik Kimia Palembang, 19 Juli 2006 Oleh Setiadi setiadi@che.ui.edu or hasbila@eng.ui.ac.id SMS. 08159088431 Department Of Chemical Engineering Faculty Of Engineering - University Of Indonesia Proses Katalitik Aseton Aseton : senyawa organic polar yang dapat diproduksi dari materi hayati renewable mll. fermentasi, pirolisis , maupun new process via supercritical decomposition ZSM-5 Hidrokarbon C1- C10 C1 : CH4 C2 : C2H4, C2H6 C3 : C3H6, C3H8 C4 : C4H8, C4H10 C5 : C5H10, C6 : C6H6, C6 alifatik C7 : Toulena, Alifatik, C8 : Xylena, alifatik C9 : Mesitylene (1,3,5 TMB) C10 : Durene, Naphthalene Kemampuan shape-selectivity ZSM-5 terletak pada bangunan struktur kristalnya yang diameter/bukaan pori sekitar 0,56 nm dan hampir homogen. Katalis ZSM-5 banyak digunakan untuk transformasi reaksi-reaksi hidrokarbon dibanding dgn. ZSM-5 digunakan reaksi senyawa organik polar Geological Time Frame Process (Millions years) Biomass derived liquid Fossil Resources – Crude Oils (C1-C40) Hydrocarbons Biological time frame Transformation & Utilization Fuel : LPG (C3-C4 H.Cs), Gasoline(C5-C10 H.Cs), Diesel Fuel, Kerosene, Avian Jet Fuel, etc Biomass Materials Fuel Combustion Waste biological activities Fotosintesis CO2 H2O CO2 Un-converted CO2 The Concept Carbon Cycle Route for renewable biomass and non-renewable as the origins of hydrocarbons for fuels & chemicals (developed from Kojima, 1998; Metzger & Eissen, 2004 dan Padabed et al.,2002) Resources Non-renewable Fossil Resources (Petroleum crude Oil) Scope of this Research Work Target Compounds Refinery Process & Catalytic Cracking Unit (FCC) C1-C10 Aromatic Compounds Renewable Fuel (Gasohol), (O.N., RVP) Petrochemicals Ethanol Acetone, Butanol Biomass Materials •Minyak Nabati ( Sawit, Jarak, ) Biomass-derived liquid from fermentation Products (sagu, singkong, tetes tebu/molasses, 80 % Yield Limbah Tandan Kosong Sawit, dll.) Biomass-Based Technology established ??? •Catalytic Reaction Process? Catalyst ? HZSM-5 & Nat. Zeolite •Reaction condition? A Schematic Diagram of C1-C10 Hydrocarbons Route from the Origin Reaction at the internal or external surface of Zeolite O ║ 2 [ H3C-C- CH3] Self Aldol condensation 2 molecules of Acetones Acetic acid Decomposition CH4 COx O OH ║ │ CH3 C CH2 C (CH3)2 Mesityl oxide (MSO) Diacetone alcohol (DAA) Further self Aldol condensation + (CH3)2CO - H2O Cracking inside the Pores at higher Temp > 350 oC C3-C4 LPG O ║ (H3C)2C=CHCCH=C(CH3)2 phorone or diisopropylideneketone O Dimerization Condensation – Dehydrocyclization C5-C10 H.Cs of Gasoline (Shape Selective Formation) Monoaromatic : Benzene Xylene Toluene EthylBenzene C9 monoaromatic C10monoaromatic O ║ H3C- C-CH=C(CH3)2 Dehydration - H2O In progress of reaction: Continued condensation, forming higher molecular weight species which may accumulate in pore channel and shutting down the reaction isophorone Diaromatics : Napthalene Monomethylnaphthalene Dimethylnapthalene Trimetylnaphthalene Tetramethylnapthalen Reaction at the internal surface of ZSM-5 H3C CH3 O CH=C H3C ║ CH3 C=CH-C-CH=C H3C CH3 C=HC CH=C H3C CH3 C=HC 1,3,5Trimethylbenzene (Mesitylene) Reaction at the external surface of ZSM-5 A reaction mechanism for the acetone conversion for C3-C4 or C5-C10 Aromatic hydrocarbons formation Tracking Acuan untuk Mekanisme Reaksi Chang C.D dan A.J. Silvestri, 1977, The conversion of Methanol and Other O-Compounds to hydrocarbons over Zeolite Catalysts, Journal of Catalysis, 47, 249-259 Chang, Clarence D., W. H. Lang, and W.K. Bell, 1981, "Molecular Shape-Selective Catalysis in Zeolite," in Catalysis of Organic Reactions edited by William R. Moser, Marcel Dekker Inc., 73-94 Xu, Teng, Eric J. Munson, and James F. Haw, 1994, "Toward a Systematic Chemistry of Organic Reactions in Zeolites: In Situ NMR Studies of Ketones," J. Am. Chem. Soc., 116, 1962-1972 Hutchings, Graham J., Peter Johnston, Darren F. Lee, Ali Stair Warwick, Craig D. Williams and Mark Wilkinson, 1994, "The conversion of methanol and other O-compounds to hydrocarbons over zeolite β", Journal of Catalysis 147, 177-185 Lucas, A., P. Canizares, A. Duran, A. Carrero, 1997, "Dealumination of HZSM-5 zeolites : Effect of steaming on acidity and aromatization activity," Appl. Catal. 154, 221 Stevens, Mark G., Denise Chen and Henry C. Foley, 1999, "Oxidized Cesium/Nanoporous Carbon Materials: Solid-Base Catalysts with Highly Dispersed Active Sites," J.C.S., Chemical Commun., 275-276 Dehertog, W.J.H., G.F. Fromen, 1999, "A catalytic route for aromatics production from LPG", Applied Catalysis A: General 189 63-75 Zaki, M.I., M. A. Hasan, F.A. Al-Sagheer, and L. Pasupulety, 2000, "Surface Chemistry of Acetone on Metal Oxides: IR Observation of Acetone Adsorption and Consequent Surface Reactions on Silica-Alumina versus Silica and Alumina," Langmuir, 16, 430-436 Xu, M., W. Wang and Michael Hunger; 2003, " Formation of acetone enol on acidic zeolite ZSM-5 evidenced by H/D exchange", Chem Commun, 722-723 Shift Selectivities Due to The Temp. Changes Contoh : 2 (dua) Temp. 350 oC & 400 oC untuk produk • Isobutene • Aromatics • Aliphatics • COx (1,3,5 Trimetilbenzena) Konversi Aseton & Sensitivitas Pergeseran Selektivitas Produk terhadap Suhu Reaksi (Sumber : Chang, Lang, & Bell, 1981, Catalysis of Organic Reactions by William R. Moser (Editor), Marcel Dekker Inc., 73-94) Basic unit building block-AlO4 or SiO4 tetrahedra structure Ten-membered oxygen ring structure Secondary building block, Chains of 5membered oxygen rings Secondary building block, Chains of 5membered oxygen rings Vertically -cross sectional view Straight channel, Elliptical openings 0.51 x 0.55 nm Zig-zags channel, Circular openings 0.54 x 0.56 nm The Framework of ZSM-5 structure Acidic protons migrate between the four oxygen atoms surrounding the tetrahedral aluminum center in the following fashion (Ryder, dkk., J. Phys. Chem. B 2000, 104, 6998) (Source : Sierka and Sauer, J. Phys. Chem. B 2001, 105, 1603-1613) Ilustrasi difusi molekul senyawa Hidrokarbon diseputar mulut pori zeolit Pore Dimension for some Zeolites Zeolite Pore size, nm Y 0.72 Mordenite 0.67 x 0.7 Offreite 0.64 ZSM-5 0.54 x 0.56 Ferrierite 0.43 x 0.55 Erionite 0.52 x 0.36 Objectives : • To observe the Performance of HZSM-5 on Time on stream Stability (TOS) on the Acetone Reaction to get the high as possible acetone conversion, Aromatic Yield and Product Selectivity • The influence of Si/Al ratio, Temperature during TOS Catalytic Tests Experimental Method Wacetone?? 6 mm , i.d N2 Flow meter Pump Preheater Acetone fed by pump Acetone 19 cm Quartz sand liquid drop Quartz Wool Quartz sand Electric furnace (1000W) N2 gas Termokope1 Unggun Katalis Mixture of ZSM-5 & quartz sand 16 cm Lokasi Pengukuran Suhu Unggun Katalis Stainless steel rod Quartz Wool Batangan Baja SS 316 Wproduk cair?? 35 cm Reaktor Pipa, 10 mm o.d., SS 316 Gas product Ice - water bath Wproduk gas?? Experimental Set-up for Catalytic Test Skema Diagram Penyusunan Katalis dalam Reaktor Pipa Experimental Method Experimental conditions Catalyst Origin : H-ZSM-5 : Japan (Commercial) Si/Al ratio Particle size (dp) Weight of catalyst for bed : 25 -100 : 3 meter : 1 gram Quartz sand for blending Quartz sand for preheating Aceton (Cica) : 5 gram (10-15 mesh) : 7 gram (10-15 mesh) : min 99.5% purity Carrier Gas : N2 Experimental Method Data GC-FID ( Hewlett Packard ) for Analysis of liquid product Column DB-1 (100 % DimethylPolysloxane), non-polar 60 m x 0.25 mm I.D., 0.25 μ (film) JW : 122-1062-JW Carrier Nitrogen Oven 40 oC for 2 min; 40 - 220 oC with heating rate at 2.5 o C/min Injector Split 1:100; 260 oC Detector FID 290 oC Nitrogen make up gas sebesar 30 ml/min The condition of GC-TCD for gaseous product Gas Chromatography GC 1 (organic) GC 2 (In-organic) Column Porapaq Q Mol. Sieve Carrier gas Helium Argon Column Oven 80 oC 60 oC Injection port 90 oC 80 oC Detector (TCD) 90 oC 80 oC Experimental Method Waktu retensi hasil deteksi chromatogram GC-FID kolom kapier DB-1 Posisi keberadaan Peak dikonfirmasi dgn.GC-MS Larutan Standard murni/ campuran Peak No. Compounds Retention time, minute Calibration factor 1 Acetone ~6.25 2.2 2 C5-C6 Aliphatics 6.1-9.3 1 3 Benzene 7.98 1 4 Toluene (B.P. - 110.6 oC) 9.87 1 5 Ethylbenzene (B.P. – 136.3oC) 11.85 1 6 m+p-Xylene (B.P. – 137-138 oC) 12.1 1 7 o-Xylene (B.P. - 144 oC) 12.6 1 8 C9-Aromatics group* 13.8-15.6 1 9 C10-Aromatics** 16.6-17.7 1 10 Naphthalene - 18.5 1 11 MMN group- 20.5-21.0 1 12 DMN 22,3 1 13 TMN 23.3-24 1 * n-Propylbenzene, 1-Methyl-3-Ethylbenzene, 1-ethyl--Ethylbenzene, 1,3,5-Trimethylbenzene (Mesytylene), 1Methyl-2-Ethylbenzene, 1,2,4-Trimethylbenzene, 1,2,3-Trimethylbenzene ** 1,4-Diethylbenzene, n-butylbenzene, 1,2 diethylbenzene, 1,2,4,5-Tetramethylbenzene, 1,2,3,4Tetramethylbenzene Experimental Method Waktu retensi produk gas menggunakan GC-TCD Peak Component Retention time, min Poropak - Q Mol.Sieve Calibration Factor 1 CO2 0.9 0.91659 2 C 2 H4 1.4 0.87553 3 C2H6 1.8 0.80699 4 C 3 H6 5.2 0.67475 5 C4 12.8 0.56479 6 H2 1.7 0.10501 7 CH4 4.1 0.34531 8 CO 4.7 1.00367 Experimental Method Ethanol-Absorben Un-reacted Acetone C5-C6 aliph., 6.1-9.3‘ Benzene , 7.98' Toluene , 9.87‘ Ethylbenzene, 11.85‘ m+p-Xylene , 12.1‘ O-Xylene,12.6' C10-aromatik ,16.6-17.7‘ C9-aromatik (Trimethylbenzene) , 13.8-15.6' Naphthalene, 8.5‘ Methylnaphtahlene (MMN) , 20.5-21.0' Dimethylnaphtahlene (DMN) , sekitar 22.3' Trimethylnaphtahlene (TMN), 23.3-24 Tipikal GC-FID Chromatogram sampel produk cair Note Kandungan Hidrokarbon dalam sampel produk cair juga telah dikonfirmasi dengan GCMass Spectrosmeter Experimental Method Tipikal Chromatogram GC-TCD sampel produk gas C2H4 H2 N2 –Carrier gas C2H6 CH4 C3H6 CO C3H8 C4 Chromatogram resulted from GC using Poropak Q Column Chromatogram resulted from GC using Molecular Sieve Column Perhitungan konv.aseton, Fraksi Liquid, Fraksi Gas Aceton Feed Trap-1 = 1601 mg Acetone C5~C6 C6+-Aliphatics Benzene Toluene Ethylbenzene m+p-Xylene o-Xylene C9-Aromatics C10-Aromatics Naphthalene 2-Methylnaphthalene 1-Methylnaphthalene Dimethylnaphthalene Trimethylnaphthalene Absorption Trap-2 : Component Ethanol Acetone Benzene Toluen 3cc during 34.5 min. wt% (FID) 0.373 2.64 8.68 3.85 23.14 3.82 24.12 7.27 19.24 1.74 1.33 1.21 0.17 1.92 0.495 9707 Area 5156933.0 13091.8 11702.5 12089.5 Correction 0.8206 2.64 8.68 3.85 23.14 3.82 24.12 7.27 19.24 1.74 1.33 1.21 0.17 1.92 0.495 mgram FID Factor 1.51E-07 1.53E-07 6.913E-08 6.913E-08 30 1035 area 1435406 196823 17485 204423 37351 43612 8111 61208 141126 158055 ml/min for ml Factor 1 0.105096 1.00367 0.916593 0.345307 0.875529 0.806991 0.6747475 0.652652 0.564794 wt%(recalc) 0.817 2.628 8.641 3.833 23.037 3.803 24.013 7.238 19.155 1.732 1.324 1.205 0.169 1.911 0.493 mg 13.08 42.08 138.35 61.37 368.83 60.89 384.45 115.88 306.67 27.73 21.20 19.29 2.71 30.60 7.89 7.79E-01 2.00E-03 8.09E-04 8.36E-04 %w 99.53 0.26 0.10 0.11 Acetone Conversion Gas Product Yield 98.37 27.60 34.5 amount 1435406 20685 17549 187373 12898 38184 6546 41300 92106 89269 % wt % min % mol 73.94 1.07 0.90 9.65 0.66 1.97 0.34 2.13 4.74 4.60 Aceton Feed [mg] 2329.50 Product in Trap1 [mg] 1641.41 % Carbon ? Product in Component, mg 9661.746 24.848 10.037 10.369 Gas Phase Products N2 rate Vol. N2 Component N2 H2 CO CO2 CH4 C2H4 C2H6 C3H6 C3H8 C4+ Aliphatics Metode Penelitian vol/mmol Nitrogen mmol 43.50 0.63 0.53 5.68 0.39 1.16 0.20 1.25 2.79 2.71 Liq. Oil Product Yield trap 2 [mg] 45.254 % Carbon ? Product Gas [mg] 23.794872 43.496767 Mol. Weight 28 2 28 44 16 28 30 42 44 58 Total output [mg] 72.40 642.84 ml/mmol mmol mg 1218 1 15 250 6 32 6 53 123 157 2329.50 wt % %C? Selectivities &Yield Experimental Method 0.58 98.37 Interval of sample Acetone conversion CO CO2 CH4 C2H4 C2H6 C3H6 C3H8 C4+ Aliphatics C5~C6 Aliphatics C6+-Aliphatics Benzene Toluene Ethylbenzene m+p-Xylene o-Xylene C9-Aromatics C10-Aromatics Naphthalene 2-Methylnaphthalene 1-Methylnaphthalene DMN TMN weight in g 14.89 249.83 6.25 32.40 5.95 52.56 122.81 156.89 42.08 138.35 61.37 368.83 60.89 384.45 115.88 306.67 27.73 21.20 19.29 2.71 30.60 7.89 2229.51 Product composition % weight 0.67 11.21 0.28 1.45 0.27 2.36 5.51 7.04 1.89 6.21 2.75 16.54 2.73 17.24 5.20 13.75 1.24 0.95 0.87 0.12 1.37 0.35 100.00 h % % carbon 0.31 3.31 0.23 1.59 0.29 2.58 6.03 7.70 2.07 6.79 3.01 18.11 2.99 18.87 5.69 15.05 1.36 1.04 0.95 0.13 1.50 0.39 100.00 Selectivities by %C Si/Al=25, TOS =17 h stable at ca.100% Conv. Results & Discussions Conversion [wt%] 100 90 Si/Al=100 80 Si/Al=25 Si/Al=25 Si/Al=75 70 60 Si/Al=75 Si/Al=100 50 40 30 20 10 0 0 5 10 15 20 25 30 Time on stream [h] Acetone conversion over HZSM-5 by various Si/Al mol ratio. WHSV = 4 h-1, N2 carrier = 30 ml/min. Results & Discussions Conversion [wt%] TOS <= 17 h stable at ca.100% Conv. 100 90 80 70 60 50 40 30 20 10 0 723 K 673 K 623 K 573 K 0 5 10 15 20 25 30 Time on stream [h] The stability of H-ZSM-5 Si/Al =25 on various reaction temperature Results & Discussions Monoaromatic yield [wt%] 100 723 K 673 K 80 TOS < 13 h, Yield > 60% 623 K 60 573 K 40 20 0 0 5 10 15 20 25 30 Time on stream [h] Yield of monoaromatic duing time on stream on various temperature Results & Discussions Trimethylnaphthalene TOS = 40 min Dimethylnaphthalene Diaromatik TOS = 70 min 1-Methylnaphthalene 2-Methylnaphthalene TOS = 100 min Naphthalene C10-Aromatics H-ZSM-5 → High Shape Selective for Aromatic Formations, Total Select. > 60 % C9-Aromatics Monoiaromatik o-Xylene m+p-Xylene Ethylbenzene Toluene Benzene C6+ aliphatics C5~C6 aliphatics C4 aliphatics Alifatik C3H8 C3H6 C2H6 C2H4 Product Selectivity within 100 min with H-ZSM-5 Si/Al=25 CH4 COx CO2 CO 0 25 Selectivity (% carbon) 50 Results & Discussions 100 100 Monoiaromatik 60 40 C4 Aliphatics 20 80 Selectivity [ % Carbon] 100 80 Monoiaromatik 60 40 C4 Aliphatics 20 0 0 0 10 20 Time on stre am [h] 30 Si/Al=100 and T= 673K Si/Al=75, T=673K Selectivity [ % Carbon] Selectivity [ % Carbon] Si/Al=25, T=673 K Monoiaromatik 80 60 40 20 C4 Aliphatics 0 0 10 20 30 Time on stre am [h] 40 0 10 20 Time on stre am [h] Fig. 6 The change of monoaromatic and C4 aliphatics selectivity during the progressing of time on stream reaction Note •The relative symmetry in the opposite direction between the increasing of C4 aliphatics and the decreasing of monoaromatic selectivity •The shift selectivity between the change of monoaromatic and C4 aliphatics selectivity during TOS 30 Conclusions •ZSM-5 with Si/Al = 25 is the high active and stable than the Si/Al ratio, it indicates that the reaction of acetone reaction required a high acid density on the surface of catalyst. •The reaction on 673 K is a favorable temperature for acetone conversion toward aromatic products. The lower temperatures of reaction lead to rapid deactivation, and the higher temperatures tend to decline the yield/selectivity of aromatics products •The formation of aromatic compounds come from the C4 aliphatics and big possibilities that the loss of activity of catalyst and shift selectivity are caused by coking which covers the surface acid sites of ZSM-5 Terima kasih kpd. Prof. T. Kojima, Staffs & the Excellent Students, Faculty Engineering, Seikei University, TokyoJapan Prof. T. Tsutsui Applied Chemistry & Chem. Engineering, Kagoshima University, Kyushu-Japan Prof. Takao Masuda, Div. of Material Science and Eng., Graduate School of Eng., Hokkaido University, Sapporo, Japan The surface area for fresh and used catalyst Total area, m2/g Micropore area, m2/g Fresh 321.8 209.4 Used 225.4 159.9 Fresh 294.4 248.2 Used 235.3 155.8 Fresh 115.4 58.3 Used 76.0 44.2 Catalyst HZSM-5 HNZ (protonated Nat. Zeolite) 15 wt%B2O3-HNZ The powder of Fresh Catalyst, the white color The change of color for the powder of used Catalyst to be black or dark brown Effect of Boron oxide loading into HNZ catalyst on Product Reaction 25 wt%B2O3HNZ HNZ 5 wt% B2O3-HNZ 15 wt%B2O3HNZ Temperature [oC] 400 400 400 Conversion 98.9 98.4 95.8 20.3 CO 0.31 0.63 0.65 0.36 CO2 2.93 3.66 5.45 4.85 CH4 0.21 0.27 0.30 0.10 C2H4 1.0 2.96 4.11 0.17 C2H6 0.31 0.24 0.10 0.00 C3H6 1.55 5.82 12.60 1.26 C3H8 6.90 4.02 1.84 0.00 C4 aliphatics 7.35 9.69 20.30 61.70 C3-C4 Hydrocarbons 15.80 19.53 34.74 62.96 Liquid Hydrocarbon 77.30 72.80 54.70 31.50 Catalyst [%] Product distribution (% w) The comparation of the results due to the water addition into acetone feed Feed Acetone acetone + H2O (50% wt add) Temperature, [oC] 400 400 LHSV [h-1] 2.18 4.32 Conversion [%] 98.9 99.1 Benzene 5.64 4.24 Toluene 21.12 18.26 Ethylbenzene 1.44 1.79 m+p-Xylene 15.38 16.01 o-Xylene 4.67 4.9 C9-Aromatics 7.22 9.36 Naphthalene 0.49 0.65 2-Methylnaphthalene 1.64 1 1-Methylnaphthalene 0.59 0.32 Dimethylnaphthalene 1.83 1.17 Trimethylnaphthalene 0.16 0.24 Product (wt %) 6 100.0 5 Si/Al=25 80.0 4 70.0 60.0 3 Paraffin/Ol efin 50.0 40.0 30.0 2 1 20.0 Paraffin/Olefin ratio Acetone conversion, % 90.0 0 10.0 -1 0.0 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 Time on stream [h] The change of acetone conversion along with Paraffin/olefin ratio during reaction over ZSM-5 (Si/Al=25) Reaction condition : Temperature = 673 K, P=0.13 MPa, WHSV= 4 g/g.h, N2 carrier = 30 ml/min