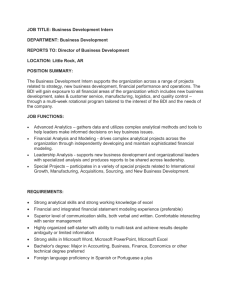

Microsoft in Manufacturing

Operations

Sam Youness

WW Industry Technology Strategist

Microsoft Corporation

What are we going to cover?

Microsoft and its partners in manufacturing operations

Microsoft focus areas in manufacturing operations

Manufacturing visibility pillars

Collaboration

Integration

Business intelligence

Security

Virtualization

Q&A

Manufacturing Environment SP95 Levels

Relative Network

Response

Requirement

Overview

Network Levels

Min. to Hour

Response

Enterprise Network

4

Control System Network Zone

3

<5 Minute Data

Update Time

MES Network

0, 1, 2

Critical Controls Network Zone

1 -2 Second Data

Update

HMI Network

Interlock Network

I/O Network

<1 Second Data

Update

I/O Network

<.1 Second Data

Update

Enterprise Asset Management

(EAM/SAM)

Control Systems, DCS, &

Automated Equipment

Production Control/MES

SCADA and HMI

Shipping/Receiving Materials

Handling

Laboratory Information

Management

Quality Management

Document Management

Regulatory Affairs EH&S

Typical Plant Operation Applications

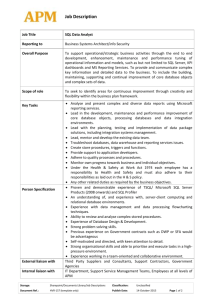

Manufacturing Solutions

Customer Requirements

System Integrators

Independent Software Vendors

Microsoft Solutions Offerings

Six Sigma and RosettaNet Accelerators

Microsoft Products and Technology

.NET,Visual Studio,Windows, Office, SQL Server…..

Manufacturing Partner Ecosystem

Microsoft and our ISV’s – One Solution

Vendor Solution

Scorecards

Dashboards

Analytics

Planning

• OLAP analysis

• Provide visibility into

business operations and

factors impacting the

business

• Allowing for more

flexibility and timely

decision making

• Build reliable plans fast

• Aligning plans to business

operations and driving

accountability

Reporting

Collaboration

• Create and monitor KPIs

• Visually present KPIs in a

browser, SharePoint, or

Office documents

• Allow for annotation of

KPIs for better

collaboration

• Management reports

based on the analytics

• Roll-up of data to

different levels in easy to

create and understand

reports

• Integration with SQL

Server BI: Reporting

Services

Overviews

Scorecards,

dashboards, and

KPIs:

•Ability to view

real-time, historical,

and business data

side by side.

• Powerful visual

dashboards delivered to

each employee desktop

• Dashboards combine

KPIs, reports, analytics,

among other things

• Integration with

SharePoint

• Special webparts

• Notifications and alerts

Budgeting

• Create models for the

business allowing for

building budgets and

submitting such budgets

using workflow

Workflow

• Integration with

SharePoint

• Allows organizations for

deeper contribution to

plans, budgets, and

forecasts

Forecasting

• Provide insight into any

trends that would help

with decision making

Administration

• Centrally managed

budgets, plans, forecasts

• Allowing models with

business rules

• Integration with Excel

for modeling and

consistent forms

• Role-based security

Blending

Operations:

•Date validation,

•Quality Assurance

Manufacturing

Visibility

• Enhanced visibility

into manufacturing

operations.

• Continuous process

improvement

• Enhanced planning

• Asset efficiency

increase

Process Operations,

Equipment

Monitoring:

•Monitor

equipment usage

and labor cost

•Forecast

maintenance events

Quality:

•Enhancement,

• Monitoring,

• Triggers and

• Events

Inventory:

•Tracking,

Forecasting,

•Integration with

Supply-Chain and

clear view of

material usage

Support for

Industry Specific

KPIs:

•Support for S-95

structures

•Rapid deployment

and flexibility

Consolidation

• Allowing users to analyze

their data, monitor

progress, and plan their

business in the same

application

• Integration with SQL

Server BI and with Office

tools: Outlook, Excel,

SharePoint

Analytical

Foundation:

• Powerful data

model feeding into

the dashboards and

portals

• Secure

• scalable

• Reliable

• Workflow support

• Low TCO

Collaboration

Foundation:

• Workflow support

• Integration

between

intelligence and

execution.

Enterprise Applications Integrated With Plant Operations

Customer Relationship

Management (CRM)

Control Systems, DCS and

Automated Equipment

Enterprise Asset

Management (EAM/SAM)

Shipping/Receiving

Materials Handling

Supply Chain Management

(SCM)

Business

Intelligence and

Enterprise

Performance

Management

Enterprise Resource

Planning (ERP)

Production Control/MES

Plant Operations

Floor

Plant

Visibility

Enterprise

Manufacturing

Visibility

SCADA and HMI

Quality Management

Laboratory Information

Management

Product Lifecycle

Management (PLM)

Document Management

Regulatory Affairs EH&S

Missing Link: Plant Operations Impact on Results Inventory, Processes, Orders, Resources, Status,

Downtime, Products, Lab Results, Exceptions

Plant Operations Focus Areas Mapped to ISA-95 Functional

Hierarchy

Plant Floor Visibility

Business Planning

Level 4

Level 3

Quality

and Logistics

Manufacturing

Manufacturing

Operations and Control

Execution

ERP

MES

Maintenance

Continuous

Discrete

Levels Batch

Control

Control

Control

Control

2,1,0 Manufacturing Control Systems

Microsoft Plant Floor Visibility Pillars

Security

Infrastructure

Plant Operations

Integration

Collaboration

Enterprise

Manufacturing

Visibility

Analytics

Integration

Enterprise

Business Processes

Aggregating data from various

sources and interoperating

between groups

Analytics

Converting aggregated

data into information

Collaboration

Sharing the right information with

the right people at the right time

Plant Floor To Enterprise Integration

Enterprise Systems

Manufacturing Execution

HIS MSMQ

Systems

SCM

HR

FIN

SSB in SQL

Server 2005

BizTalk

Plans,

Schedules

HMI / SCADA / Cell Controllers

Inventory, Labor,

Maintenance, Quality

SSIS in SQL

Products,

BOMs,

Routings,

Recipes,

Server

2005

Procedures

Alarms

and

Events

History

Production and Process Data

Windows

Communication

Foundation

Automation and Control Systems

DCS/PLC/LIMS

Tags

Variables

Data Points

PerformancePoint/SharePoint/Other

CRM

Integration Standards Progress In Manufacturing

Standards boost interoperability over time

Multiple vendors build to standards

1994-Future

OAGIS

XML Bus. Obj

Docs/Msgs

1996-Future

SCOR Make

Model and

Metrics

2002 – Future

WBF B2MML

XML Schemas

Manufacturing Integration Standards Timeline

1995-2001

OPC

Device

Connectivity

1997-Future

ISA 95

Enterprise

Control SI

1988-2003

ISA SP88

Batch

Control

2005-Future

ISA, WBF

OAGIS

Unify models

Ten Years of Microsoft BI … and beyond

PM

Corporate

Decisions

BI

Personal and

Team Insights

DW

BSM

Excel ‘9’

Sound

Data

OLAP

1998

SSRS

PPS V1

PPS V2

Excel ‘14’

MOSS BI

Self-Service

Embedded BI

Excel ‘12’

Enterprise OLAP

EDW

MDM

2008

Wave 14

What Analysts are Saying…

Driving Analytics To Increase Manufacturing

Intelligence

CRM

FIN

HMI / SCADA / Cell Controllers

Automation and Control Systems

DCS / PLC / LIMS

SQL Server 2005\8

Reporting Services

Plans,

Schedules

SQL Server 2005\8

Analysis Services

Manufacturing Execution

Systems

HR

PerformancePoint

BSM 2005

SQL Server 2005\8

Integration Services

Operational Tactical Strategic

Enterprise Systems

SCM

Inventory, Labor,

Maintenance, Quality

Products,

BOMs, Routings, Recipes,

Procedures

Alarms

and

Events

History

Production and Process Data

Tags

Variables

Data Points

Excel & Excel Add-in

SQL/AS

Collaboration In Manufacturing

CRM

Enterprise Systems

SCM

HR

FIN

Enterprise Content

Management

Manufacturing Execution

Systems

SharePoint

Portal

Inventory, Labor,

Plans,

Schedules

Automation

and Workflow

HMI / SCADA / Cell Controllers

Maintenance, Quality

Products,

BOMs, Routings, Recipes,

Procedures

Alarms

and

Events

History

InfoPath

Production and Process Data

Automation and Control Systems

DCS / PLC / LIMS

Tags

Variables

Data Points

The Architecture

Collect

Store and

Integrate

Validate

Visualize and

Analyze

Smart client or

portals

Data

Collection

from various

sources

·

·

·

·

Site 1

Analysis Server

Reporting Server

Adhoc Reporting

Drill-down

PLC/DCS

Site 2

Site 3

Site 4

Rich User

Experience

Launch

from

portal

Workstation

Hand

helds

Share and Collaborate

Enterprise Application Interface (EAI)

Orchestration, Workflow, Integration,

Transformation, Rules Engine, BPEL

Web Services

Extension

Oracle

DB

(Operations

data)

Historians/

Realtime Data

Existing LOB and

Legacy Apps

Plant Manager

Portal

SQL Server

2005

(Doc Archive,

Meta-data,

Cubes)

Professional

Journals

Electronic Collaboration

Framework (ECF)

Infrastructure

Office Suite Integration

integrates with SPS/

WSS and document

management system

Office Business Applications

Connecting Office Clients to Business Data

Office

Business

Applications

Unified Communication

& Collaboration

Business Intelligence

Content Management

2007 Office system clients

Open XML File Formats & Extensible Fluent Interface

Office SharePoint Server 2007

LOB Apps, Data

Warehouses,

Trading

Pargnetrs, etc.

SAP

Siebel

Oracle DB

Office

Communications

Server 2007

• Search

• Workflow

• Business Data Catalog

• Website & Security Framework

• Excel Services

Exchange Server

2007

Microsoft

Office

System

Manufacturing Operations Security

New Trends!

GAO Report in 2004: “Critical Infrastructure Protection –

Challenges and Efforts to Secure Control Systems”

Control systems are adopting standardized technologies

with known vulnerabilities

Control systems are connected to other networks

Insecure connections exacerbate vulnerabilities

Information about infrastructures and control Systems is

publicly available

Challenges When Implementing Security

Why the

*&(^%$

do I need

security?

Security Components

Technology

Comprehensive Security Product Portfolio

Whale Communications Intelligent

Application Gateway

• SSL-based access

• Deep application protection

• Endpoint security management

Services

Edge

Server

Applications

Information

Protection

Client and

Server OS

Identity

Management

Systems

Management

Active Directory

Federation Services

(ADFS)

Guidance

Developer

Tools

A comprehensive line of business security

products that helps you gain greater

protection through deep integration and

simplified management

Client and

Server OS

Server

Applications

Edge

Best Practices

Isolation of systems that require updates either individually or by

isolating the entire plant network

Use of firewalls and Perimeter Networks to isolate the plant floor

networks

Encourage employees to follow established security policies and

procedures through continued education and collaborative efforts

with corporate IT departments

Isolate systems running legacy operating systems from the rest of the

plant network.

Use tools such as the Microsoft System Center Operations Manager

2007 to make it easier to monitor security logs from multiple

systems

Scan and lock down the workstations and servers, disabling nonessential features and services

System Isolation

No direct connection of PCN and SCADA networks to the Internet:

Prevent unsolicited traffic from the Internet

Prevent DoS attacks on the PCN…

Outgoing traffic could congest the PCN; also, embedded object could compromise it (Java

applets, ActivX, etc.)

Proprietary corporate data could be intercepted

Restrict access from enterprise network to control network

Authorized access to shared enterprise/control servers (such as

historian databases, maintenance databases)

Secure methods for authorized remote support of control systems

Secure connectivity for wireless devices if used

Well-defined rules for permitted traffic on a network (ACLs,

VLANs)

Traffic monitoring – attempting to enter and already on the PCN

Secure connectivity for firewall management traffic

Application Virtualization

What is MS Application Virtualization?

An engine that turns applications into centrally managed

virtual services that are delivered on-demand.

Why Virtualize Applications?

Continual rollout of new applications, updates, patches...

Application conflicts

Centralized management and reporting efficiencies

Need for improved security and reporting

Disaster recovery, business continuity pressures

Operating System migration

Image management issues

Roaming users / free seating

Terminal Services / Citrix consolidation

Application licensing tracking and management

Demand for faster provisioning (self provisioning)

* Gartner, Forrester, Economist

Application Virtualization

Applications are virtualized per

instance:

Files (incl System Files)

Registry

Fonts

.ini

COM/DCOM objects

Services

Name Spaces

Semafores, Mutexes

Applications do not get installed or

alter the operating system

Yet tasks process locally on the host

computer.

© 2008 Microsoft Corporation. All rights reserved. Microsoft, Windows, Windows Vista and other product names are or may be registered trademarks and/or trademarks in the U.S. and/or other countries.

The information herein is for informational purposes only and represents the current view of Microsoft Corporation as of the date of this presentation. Because Microsoft must respond to changing market

conditions, it should not be interpreted to be a commitment on the part of Microsoft, and Microsoft cannot guarantee the accuracy of any information provided after the date of this presentation.

MICROSOFT MAKES NO WARRANTIES, EXPRESS, IMPLIED OR STATUTORY, AS TO THE INFORMATION IN THIS PRESENTATION.