Operation of Induction Heating ,Core type and Coreless Induction

advertisement

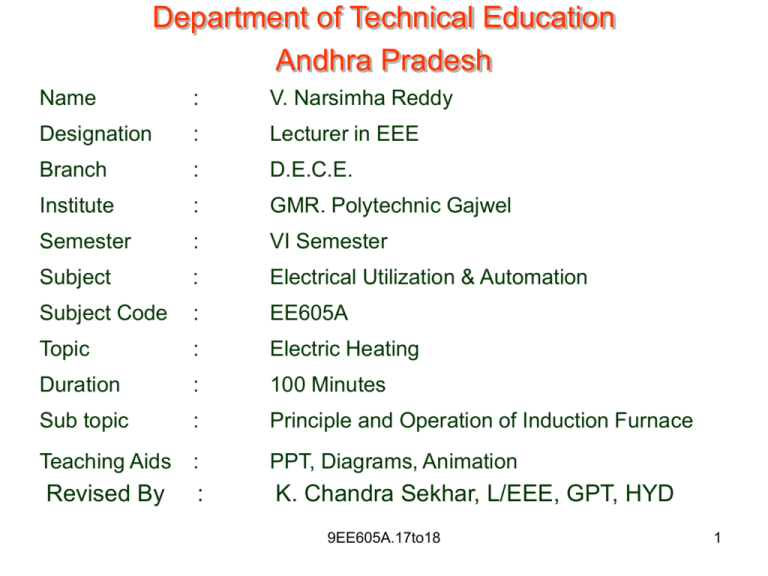

Department of Technical Education Andhra Pradesh Name : V. Narsimha Reddy Designation : Lecturer in EEE Branch : D.E.C.E. Institute : GMR. Polytechnic Gajwel Semester : VI Semester Subject : Electrical Utilization & Automation Subject Code : EE605A Topic : Electric Heating Duration : 100 Minutes Sub topic : Principle and Operation of Induction Furnace Teaching Aids : PPT, Diagrams, Animation Revised By : K. Chandra Sekhar, L/EEE, GPT, HYD 9EE605A.17to18 1 Recap In the last class you have learnt about • Electric Arc Heating • Types of Arc Furnaces • Direct • Indirect • Applications of Direct and Indirect Arc Furnaces 9EE605A.17to18 2 Objectives On completion of this topic you would be able to know • Operation of Induction Heating • Core type and Coreless Induction Heating 9EE605A.17to18 3 Induction Heating • Induction heating is also known as high frequency heating • Induction heating process makes use of currents. induced by electromagnetic action in the material to be heated • It uses transformer principle • Conversion of electromagnetic energy into heat energy takes place in the material, it self 9EE605A.17to18 4 Induction Heating • Heat transfer by high frequency heating is as much as 10,000 W/cm2 • The high frequency heating can be applied mainly to two classes of materials firstly, conducting materials & secondary insulating materials • Heating of first type of materials is called induction heating and heating of Second type of materials is dielectric heating 9EE605A.17to18 5 Induction Heating Induction furnaces are further classified as i) Core type induction furnace ii) Coreless induction furnace 9EE605A.17to18 6 Core Type Induction Heating Fig.1 9EE605A.17to18 7 Core Type Induction Heating • Fig 1 shows a core type induction surface • The Core type furnace is essentially a transformer • Primary side is connected to supply • Secondary side contains charge (materials) in iron core annular hearth 9EE605A.17to18 8 Core Type Induction Heating • The charge is magnetically coupled to the primary by an iron core • The magnetic coupling between primary and secondary is very poor resulting in high leakage current and a low power factor. For this reason the furnace is operated at low frequencies of the order of 10Hz or so 9EE605A.17to18 9 Core Type Induction Heating • Hence it is called low frequency furnace i.e., 10Hz • The low frequency necessiates an additional MG set or frequency converter • To start the furnace Molten metal is poured in the annular hearth before start 9EE605A.17to18 10 Core Type Induction Heating • Otherwise there is no material and the secondary side is open and no current will be induced • Hence no heating will take place • This is convenient where the furnace is to be used for melting different types of charges 9EE605A.17to18 11 Core Type Induction Heating • If the current density exceeds about 5A/mm2 the pinch effect due to electro magnetic forces, may cause a complete interruption of the secondary circuit 9EE605A.17to18 12 Core Type Induction Heating Disadvantages • A crucible of inconvenient shape is required • Low power factor due to poor magnetic • A M.G. or frequency converter is required • It is bulky due to the presence of core 9EE605A.17to18 13 Ajax Wyatt Vertical Core Furnace Fig.2 9EE605A.17to18 14 Ajax Wyatt Vertical Core Furnace • Fig 2 shows Ajax Wyatt Vertical Core Furnace • It is an improvement over the core type induction furnace • The magnetic coupling in this furnace is better than core type furnace • Leakage reactance is comparatively low and frequency is high, hence it is high frequency furnace 9EE605A.17to18 15 Ajax Wyatt Vertical Core Furnace • It employs vertical crucible instead of horizontal • The system avoids the pinch effect due to the weight of the charge in the main body of the crucible • The circulation of Molten metal takes place round the ‘V’ portion by convection currents 9EE605A.17to18 16 Ajax Wyatt Vertical Core Furnace • Inside the furnace is lined depending upon the charge • The top of the furnace is covered with an insulated cover which can be removed for charging • Hydraulic arrangements are usually made for tilting the furnace to remove the molten metal 9EE605A.17to18 17 Indirect Core Type Induction Furnace Fig.3 9EE605A.17to18 18 Indirect Core Type Induction Furnace • This type of furnace is used for heat treatment of metals • The wall of the container forms the secondary winding • Iron core links the primary as well as secondary 9EE605A.17to18 19 Indirect Core Type Induction Furnace • Heat produced in the secondary due to induced current is transmitted to the charge by radiation • A detachable magnetic circuit made of a special alloy is kept inside the chamber 9EE605A.17to18 20 Indirect Core Type Induction Furnace • The alloy will loose magnetic properties at a particular temperature and are regained when it cools down • On reaching the critical temperature the reluctance of the alloy increases and here by decreasing induction effect 9EE605A.17to18 21 Indirect Core Type Induction Furnace • Critical temperature varying 4000c to 10000c can be employed for heating different materials • The furnace operates at a PF of around 0.8 9EE605A.17to18 22 Coreless Induction Heating REFRACTORY CRUCIBLE PRIMARY WINDING CHARGE 9EE605A.17to18 23 Coreless Induction Heating • The coreless induction furnace operates on the principle of an electric transformer • If there is no core, the flux density will be low • For compensating the low flux density, the primary supply should have high frequency 9EE605A.17to18 REFRACTORY CRUCIBLE PRIMARY WINDING CHARGE 24 Coreless Induction Heating REFRACTORY CRUCIBLE • The furnace consists of a refractory or ceramic crucible cylindrical in shape enclosed with in a coil which forms the primary of a transformer • The furnace also may have a conducting or non-conducting container 9EE605A.17to18 PRIMARY WINDING CHARGE 25 Coreless Induction Heating • When high frequency of REFRACTORY CRUCIBLE 500 of 1000 Hz supply is given to primary windings • The eddy currents are set PRIMARY WINDING up in charge or container CHARGE by transformer action 9EE605A.17to18 26 Coreless Induction Heating • There currents heat the charge to melting point and they also set up the electromagnetic force which produce a stirring action to the charge • The furnace becomes relatively light in weight and can be easily tilted for pouring the metal 9EE605A.17to18 REFRACTORY CRUCIBLE PRIMARY WINDING CHARGE 27 Coreless Induction Furnace Advantages • High speed of heating • Well suited for intermittent operation • High quality of product • Low operating cost 9EE605A.17to18 28 Core type Induction Furnace Industrial applications • Used in foundries for melting and refining brass, zinc and other non-ferrous metals • Used for heat treatment of metals 9EE605A.17to18 29 Coreless Induction Furnace Industrial applications • These are used for steel production • These are used for melting of non-ferrous metals like brass , copper, aluminium along with various alloys of these elements • The production of carbon from ferrous alloys 9EE605A.17to18 30 Comparison Between High Frequency And Power Frequency Furnaces S. No. 1 High Frequency Power frequency Frequency converter is necessary Not required. 2 More energy required i.e, 20% to 30% for same rating. Less energy required. 3 Maintenance cost is more Less 4 Less turbulence and stirring effect More 5 Large scrap melts with more oxidation loss. Large scrap melts with less oxidation loss. 6 No special starting procedure is required Special starting procedure is required. 9EE605A.17to18 31 Comparison Between High Frequency And Power Frequency Furnaces Contd.. 7 Low capacity (few kgs. To 15 tons) furnaces are used Large capacity (above 1 tone) 8 Initial cost is more Less cost 9 High frequency (500 to 1000 Hz) Only 50Hz. 10 Well suited for intermittent operation of different alloys. Well suited for long production schedules of one alloy. 11 Care should be taken against stray field Negligible. 12 Overall efficiency is low. Overall efficient is more. 9EE605A.17to18 32 Summary In this class we have discussed about • Principle and operation of induction heating • Core type induction heating • Core less induction heating 9EE605A.17to18 33 Quiz 1.Coreless induction furnace operate on the principle of a. Transformer b. Induction motor c. Generator d. Motor 9EE605A.17to18 34 Frequently Asked Questions 1) What is induction heating ? 2) Describe briefly with a neat sketch the core type induction furnace 3) Explain the vertical core type of furnace (Ajax Wyatt furnace) with a neat diagram 4) Explain the construction and operation of coreless induction furnace 5) Explain the indirect core type induction furnace with sketch 9EE605A.17to18 35 THANK YOU 9EE605A.17to18 36