FEA of a Golf Driver and Ball

advertisement

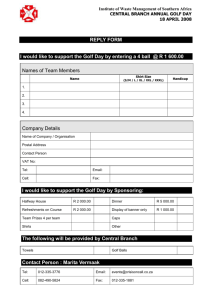

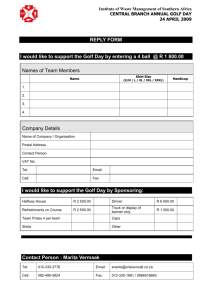

FEA of a Golf Driver and Golf Ball Solid Mechanics - ES 240 Adrian Podpirka ABAQUS Project Outline of Work Introduction to Golf Goal of Research Discussion Analysis Conclusion Theory Citations Modeling Results Golf Invented in Scotland around 1450s. Requires hitting a small ball roughly 200-500 yards into a small hole. Different clubs are used depending on distance and arc required. During the first shot, the golfer tries to hit it down course as far as possible Goals of Project To determine stress distributions in a golf ball and in a driver. To determine natural frequency of the golf ball and driver. Attempt to determine percentage of sweet spot and effect of driving distance. Learn ABAQUS FEA & Golf Only recently has FEA been used to design clubs. Programs are being made specifically to cater to the golf industry. Used to analyze swings, slicing, tendency to hook, etc. Theories Golf Ball Internal Stresses in the golf ball will arise due to sudden impact and different properties of the two materials Ball will deform as drastically as seen in the picture to the right. Frequency Measurement A closer natural frequency between the ball and the club will lead to an increase in distance. Stress Propagation Sweet spot occurs symmetrically from propagating waves. Materials Young’s Modulus E (GNm^-2) Poisson’s Ration Density (kg m^-3) Note Golf Ball Butadien Rubber .0392 .45 1150 Inner Core of Golf Ball Driver Head Iononer Resin .294 .40 Outer Core of Golf Ball Ti-6Al-4V 118 .34 4507 Standard Driver Head Material Carbon Fiber 17.2 .31 1545 Standard Shaft Material Driver Shaft 950 T. Iwatsubo et al B. Wang et al Geometry of Equipment Golf Ball 40 cm Golf Club - Wood Driver 44 cm Shaft length - 1.05 m Height - 40 mm Width - 90 mm Depth - 65 mm Golf Ball loaded linearly ramping to 15000 N. Golf Ball Sweep meshed with 1600 elements Modeled a 44 cm diameter area and partitioned off middle section. Traction load placed in between 7 & 9 Boundary Condition placed directly opposite Results Internal stresses develop as a result of mismatch of materials on the order of 40 kN. Golf ball is seen to deform. This is analogous to the picture shown before. Golf Ball Results QuickTime™ and a BMP decompressor are needed to see this picture. QuickTime™ and a BMP decompressor are needed to see this picture. Natural Frequency The closer the frequency between club and ball, the better energy transfer and therefore, farther distance. We will test the difference between hollow and solid clubs Golf Ball Meshed with 124 elements Circular edge boundary conditions Driver Meshed with roughly 169 & 171 elements Pinned at top The hollow bodied club face has a lower frequency then the solid body, closer matching that of the balls. 2D Stress Distribution Assume traction loading on face of of driver. Large deformation occurs in shaft of carbon fiber. Stress waves still occurs in driver face but much less then with coupled shaft. QuickTime™ and a BMP decompressor are needed to see this picture. QuickTime™ and a BMP decompressor are needed to see this picture. Stress QuickTime™ and a BMP decompressor are needed to see this picture. 3D Stress Note: The full 3D club could not be meshed because of element assignment errors in ABAQUS. The Natural frequency of the club could not be found. QuickTime™ and a BMP decompressor are needed to see this picture. QuickTime™ and a BMP decompressor are needed to see this picture. Analysis Full Analysis of all data and values will be given in the paper. The golf balls deformed as theory and practice indicated. By tuning golf balls to different clubs, better distances can be obtained. This would require changing either the parameters on the ball or club. Since ABAQUS was not able to mesh the merged structure, I had to forgo on the natural frequency aspect of the 3D driver. Recommendations Many of the articles could not be located since Harvard did not have a subscription to them. Many parameters Using different material parameters in order to optimize values. Dynamically loading and setting contact parameters Citations Wang et al. “Modal Properties of Golf Club Wood Driver in Different Boundary Conditions” Hocknell et al. “Hollow Club Hear Modal Characteristics: Determination and Impact Applications” Hocknell et al. “Experimental Analysis of Impacts with Large Elastic Deformation: I. Linear Motion” Iwatsubo et al. “Numerical Analysis of Golf Club Head and Ball” Penner, A. “The Physics of Golf: The Convex Face of a Driver” Newman et al. “The Dynamic Flexing of a Golf Club Shaft During a Typical Swing” Arakawa et al. “Dynamic Contact Behavior of a Golf Ball during an Oblique Impact” H. Kolsky. Stress Waves in Solids. Dover Publications Inc. Axe et al. “The vibrational mode structure of a golf ball”