what is a control release fertilizer?

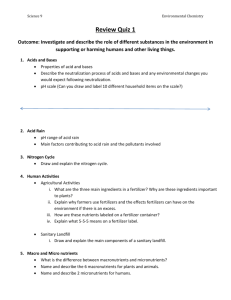

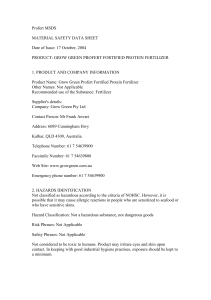

advertisement

Presentation “CONTROLLED RELEASE FERTILIZERS” By Faizan Ali (2008-ag-2470) AGR-405 Agronomy 7th CONTENTS Introduction History and Objectives Mode of nutrient release Classification of CRFs Advantages of CRFs Controlled release formulations Future needs WHAT IS A CONTROL RELEASE FERTILIZER? A synthetic fertilizer, usually encased in capsules, that releases its nutrients over a specific period of time much the same as a controlled-release drug releases its medicine INTRODUCTION Controlled-release is one of the modern application th at has enhanced how fertilizers are used both commercially and by consumers. Fertilizer use efficiency can be increased by modification of fertilizer products Chemical or Physical modificatios e.g coated encapsulation CRFs will bring revolution in Agricultural industry in near future Controlled-Release-Fertilizer CONTRLLED RELEASE FERTILIZERS HISTORY CFRs began to be used in the 1930s Reguler production started in 1936 CFRs became commercial in mid 1950s Today used in USA and Japan WHY TO USE CRFS 70 percent of conventionally applied fertilizer goes unutilized WHY TO USE CRF Loss of nutrients due to volatilization and leaching WHY TO USE CRFS Fertilizer run-off in surface water leads to oxygen depletion Negative environmental impacts Fertilizer waste through leaching increases farm expenditures Less fertilizer use efficiency Objectives Increased crop production Increased nutrient application and quality Increased fertilizer use efficiency Reduction of plant toxicity and stress Reduction in pollution of soil, water, atmosp here Reduction of fertilizer application costs OBJECTIVES Reduction of topical growth (flush growth) and clippings Improved agronomic yields Improved rooting Improved cell wall strength Improved soil microorganism health/populations Retention of desirable color MANUFACTURING OF CRFS MODE OF NUTRIENT RELEASE i. ii. A Dry mixture of soluble fertilizer and thickener in a non-permeable envelope Nutrient release in two phases water penetrates through opening to wt the mixture Nutrients release the device through pore either by diffusion or connective flows 1. POLYMER COATINGS REMAIN INTACT Water Solid Urea* Dissolved Urea Water Dissolved Urea Dissolved Urea Complete Release *Or other nutrient 2. SULFUR COATINGS BREAK DOWN Sulfur Coating H2O Solid Urea Solid Urea H2O H2O H2O +S Solid Urea H2O Dissolved Urea SCU CONTAINS INTACT AND BREACHED PARTICLES, THIN AND THICK COATINGS RELEASE OF N, BASED ON SOLUBILITY H2O Urea Urease NH4 Root RELEASE DEPENDS ON GRANULE SIZE SMALL GRANULES RELEASE FASTER RELEASE TIME The three common timing formulas are used 1. Immediate release 2. Intermediate release 3. Long term release SYSTEMATIC CLASSIFICATION a. Organic-N low-solubility compounds b. Fertilizers in which a physical barrier controls the release c. Inorganic low-solubility compounds A. ORGANIC-N LOW-SOLUBILITY COMPOUNDS I. II. Further divided into: Biologically decomposing compounds e.g urea-formaldehyde Chemically decomposing compounds e.g isobutyledene-diurea B. FERTILIZERS IN WHICH A PHYSICAL BARRIER CONTROLS THE RELEASE Granules coated by non-permeable material Material used can be hydrophobic or hydrophilic C. INORGANIC LOW-SOLUBILITY COMPOUNDS Here inorganic material is used for coating e.g: Metal ammonium phosphates (Mg NH4PO4) Acidulated phosphates rock FACTORS EFFECTING NUTRIENT RELEASE Fertilizer type (solubility, density) Thickener type Thickener concentration Size of device Temperature of soil Moisture in the soil ADVANTAGES OF CRFS Fertilizer burn is not a problem with CRFs Less frequent application is required Easier and precise mechanical application Reduced capital and labor outlay Reduced nutrient loss by leaching and run-off Reduced leaf burn ADVANTAGES Flexibility of release periods from 40 to 360 days at 25º C Reduced seed or seedling damage from high local concentrations of salts Improved storage and handling properties of fertilizer materials Product differentiation resulting in improved market potential. MARKET PRICES FOR SLOW-RELEASE FERTILIZERS Market prices of CRFs are high because of: High prices of the ingredients used for encapsulated/coated products Low production capacities significantly higher marketing and sales expenses MARKET PRICES FOR SLOW-RELEASE FERTILIZERS In the United States encapsulated granular urea is sold at a price of US$ 600.00 to 1 000.00/ton In Japan polyolefine-coated urea is sold at a price of 150 000 yen (= US$ 1 500.00 per t) In Western Europe, the average user prices are US$ 700 to 1200 per t. MARKETED CONTROLLED RELEASE FORMULATION 1.Urea-formaldehyde reaction products: also known as Nitroform, Ureaform, Methex. produced in 1936 and commercialized in 1955 2.SULFUR-COATED FERTILIZERS: Developed in 1960s and 1970s. Sulfur was used as coated material because of its low cost and value as secondary nutrient 3. Polymer-coated fertilizer Manufactured inn 1970 in Japan Polymers are used for high-value application Most common three marketed products are Nutricote, Osmocote and Polyon Cotrolled Release Fertilizer 4. MULTICOATED PRODUCTS: Fertilizer granules are heated and treated fatty acid and metal hydroxide The two react to form a coating of the metal salt of a fatty acid, such as calcium stearate Substrate coated components are nitrite, urea and triple super phosphate 5. POLYMER/SULFUR-COATED FERTILIZER: These are hybrid products that utilize a primary coating of Sulfur and secondary polymer-coated fertilizer These fertilizers were developed to deliver the nutrients at low cost APPLICATION TO SOIL LIMITATIONS Very high costs of CRFs Lack of proper legislation in most parts of the world to restrict the use of soluble fertilizers Only about 0.15% of the total fertilizers consumption is such products CRF may be inadequate sources of nutrients in situations with low ambient and soil temperatures FUTURE NEEDS Issues related to better NUE and a more environment friendly utilization of CRFs deserve greater attention and deeper insights, as listed below: Improved utilization of advanced technologies to prepare CRFs. Better understanding of the mechanisms controlling release rate and pattern FUTURE NEEDS Better assessment of expected benefits to the environment by using CRFs Development of soil degradable coatings Improved quantification of economic advantages REFERENCES 1. Jacobs, D.F., Bose, R., Hasse, D.L. “Incorporating controlled release fertilizer technology into outplanting”, in National Proceedings. Ogden, 2003, pp. 37-42. 2. Shavit, U., Shaviv, A., Shalit, G., Zaslazvsky, D.,J. Controlled Release, 1997.