Chapter 17: Costume Construction

Costume Design –

Explains the play’s characters

Cues to emotional states / social rank / financial status

Awareness of line, color, fabric, etc.

Costume Construction –

Making the design ‘live’

Responsible for building the designer’s creations

Knowledge of the processes, materials ,and

techniques of construction

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Concerns for costume construction…

Costumes must be more durable than street clothes

Capable of dealing with / expressing heightened emotional extremes

Must accommodate a wide range of motion and rigor

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Specific knowledge:

The hand of fabrics

Techniques of making and adjusting patterns

Sewing

Fabric painting

Dyeing

Distressing

Specialty skills – making of jewelry / shoes /

boots / wigs / armor

Hand: The quality and

characteristics of a fabric

that can be evaluated or

defined by a sense of touch

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

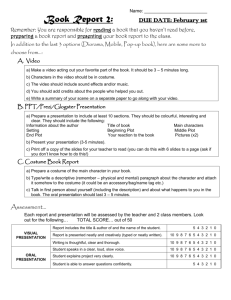

Organization of Costume Shops

In process

In performance

Costume Designer

Costume Designer

Shop supervisor

Wardrobe supervisor

Shop crew or staff

Wardrobe crew or staff

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Cutting Tables

Used for laying out patterns and fabrics

Surface needs to be smooth and also easy to push pins into

Height – average person standing won’t need to bend to work

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Dress Forms

Used for draping and pinning material

Used for adjusting patterns

Available in men’s and women’s sizes

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Fabric Storage

Storage should be easily labeled

Organize by fabric type and color

Often use ‘scrap’ pieces or use original fabrics to make alterations

Need space for bolts of fabric and large rolls of brown paper as well

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Washing Machine and Dryer

Used for standard purposes as well as dyeing fabrics

Requires a heavy-duty machine – lots of wear and tear

Continual cleaning to ensure that dyes do not remain in washer

or dryer and ruin other clothing!

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Dye Vat

Commercial = expensive

Soup kettles = cheap and workable!

Needed to heat large quantities of fabric and

liquid to achieve an even coloring of dyed

fabric

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Hot Plate

Smaller alternative to a dye vat

Works well with smaller amounts of fabric

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Stove

Residential stove will work

Can be used for heating water

Also useful when dealing with plastics or other materials for accessories

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Irons

Need heavy-duty irons to work with many fabrics

Last longer if industrial as well

Steam irons are also used

Use distilled water – prevent mineral build-up

and possible stains

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Ironing Boards

Once again – heavy-duty, industrial versions are

preferable

Specialty boards for sleeve boards and/or needle boards

are also good to have in the shop

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Steamer

Use to take wrinkles out of heavy materials such

as velvets, velour, and corduroys..

Also used for millinery

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Sink

Need hot and cold water!

Variety of uses

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Mirror

Full-length, three-way mirror needed for fittings

Want to see costume from all directions to insure correct fit

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Racks

Useful for transporting clothing from shop to various

locations in the theatre

Provides mobile hanging location

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Tables & Chairs

Needed for hand sewing and detail work – often requires many

hours in sitting position

Consider the comfort of your workers and craftspeople!

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Equipment

Sewing Machines

Straight-Stitch Sewing

Machines

Zigzag Sewing Machines

Walking-Foot Machine

(a.k.a. power machines)

Serger

(a.k.a. merrow machine or overlock)

Blind-Stitch Machine

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Sewing Equipment

Common hand tools

Measuring devices

Hand needles

Machine needles

Thread

Thimbles

Tracing wheels

Tracing paper

Tailor’s chalk

Shears & Scissors

Seam Rippers

Single-edged razor blades

Hot Glue Gun

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Costume Shop: Sewing Equipment

Common fasteners

Straight pins

Safety pins

Push pins

Snaps

Hooks & Eyes

Zippers

Velcro

Seam-Binding Tape

Buttons

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Each fabric has its own intrinsic characteristics

The hand of the fabric is used to determine a fabric’s

suitability for a particular costume

Hand of the fabric =

Type of fiber

Weave or structure of fabric

Treatment of fabric

Finish of fabric

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

2 types of textile fibers

Natural

Synthetic

Cotton

Linen

Silk

Wool

Acrylic

Nylon

Polyester

Rayon

Acetate

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Cotton

White natural fiber contained in the seed pod, or

boll, of the cotton plant

Breathes (ability to transmit heat, air, and water

vapor) well – good for performers

Accepts dyes well

Blend – combination of more

than one type of fiber, blends

are created to take advantage

of the best properties of all

fibers in the blend.

Wrinkles easily

Large number of weaves and blends available

Mercerization – soda treatment applied to cotton

which swells and straightens fibers

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Linen

Oldest textile fabric known

Comes from flax

Stronger than cotton

Silky luster

Good conductor of heat

Lint-free

Hard to dye and/or stain

Washes easily

Shrinks and creases easily

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Silk

Silkworms spin cocoons – creates silk

Expensive / Strong

Lightweight / Pliable

Good elasticity / Lustrous

Holds heat / Dyes well

Wild silk – brown with a rougher texture

Cultivated silk– Smoother texture and grayish-yellow color

Cultivation

1.Reeling – stronger & more lustrous

2.Spinning – Shorter and twists the fibers more

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Wool

Made from the fleece of sheep

2 main types

1.Woolen: Loosely twisted, soft, and weak / fuzzy textured surface / works

as an insulator – traps heat

2.Worsted: Tightly twisted, stronger, and smoother surface / breathes well

Absorbs moisture & dyes

Shrinks!!!

Wrinkles will disappear if the material is hung up – will hang out

Can be shaped with steam

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Synthetic Fabrics

Chemical compounds changed into hardened filaments through patented

processes

Tend to be slick, smooth, and dense

Do not breathe like natural fibers – tend to trap body heat

Durable

Resistant to wrinkles

Often costume designers will use blends of synthetic and natural fibers to create

garments that have the best of both worlds (50% blends of natural and

synthetic tend to breathe well but hold up to theatrical demands!)

Important to know the fabric type & blend to care for the garment once made!!!

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Synthetic Fabrics: Acrylic

Compound based on coal, petroleum, & other materials

Soft & lightweight

Does not dye well in shops but factory dyed acrylics are colorfast

Wrinkle-resistant

Little ironing needed

Common trade names: Acrilan, Orlon, Creslan

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Synthetic Fabrics: Nylon

A slurry of air, water, and coal produces the continuous-filament fiber

known as nylon

Light, strong, elastic, & resistant to abrasion

Virtually no wrinkles

Generally does not conduct moisture or heat well

Various weaves – smooth, tight (Trap heat) – loose, open (Don’t trap heat)

– Some dye well some do not

Common trade names: Antron, Capriolan, Qiana

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Synthetic Fabrics: Polyester

Petroleum-based product

Highly resistant to wrinkling

Extremely strong, commercially colorfast, reasonably stain-resistant

(Does not dye well in shop surroundings)

Used in a variety of fabrics and blends

Common trade names: Dacron, Kodel, Quintess

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Synthetic Fabrics: Rayon

One of the 1st synthetic fabrics

Regenerated cellulose – cotton linters and wood pulp…

Dyes easily, excellent colorfastness, bends well with other fabrics,

& very absorbent

Similar to silk (low-cost alternative)

Common trade names: Avril, Celanese, Fibro, Zantrel

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Synthetic Fabrics: Acetate

Similar to rayon – regenerated cellulose solution

Little strength, require low heat iron, don’t hold crease well

Good draping characteristics & wrinkle resistance

Triacetates – better than acetates – have virtues with less issues

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Weaves

How the fabric is created – generates a variety of different

textures and patterns

Threads running the length of the fabric = warp

Threads running the width of the fabric = weft / woof / fill

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

Weaves

Types of weaves…

Plain

Basket

Twill (most durable weave)

Satin (appears lustrous)

Pile (plush texture)

Plain Knit (interlocking loops)

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

A variety of fabrics are used in costume construction – a basic list…

Brocade – Slightly raised pattern – various weights – reflexive surface

Buckram – Foundation for millinery and other stiff garments

Canvas – Used mainly for lining or when durability is focus

Chiffon – Sheer – Soft diaphanous draping qualities

Corduroy – Has ridges – does not drape – low-cost sub for velvet/velour

Crepe – Low luster, soft drape – lingerie, blouses or flowing gowns

Crinoline – Has permanent sizing for stiffness

Denim – Blue-jeans and working clothes

Drill – smoother & more luster than denim

Felt – Primarily used for hats and trimming

Flannel – Men’s & women’s suits, trousers, & shirts

Gabardine – Inexpensive suits & outerwear

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics

A variety of fabrics are used in costume construction – a basic list cont…

Jersey – Knit fabric with draping qualities

Linen – Nubby, soft-luster surface – tropical suits & sportswear

Muslin – Plain, durable cotton – lining material & making patterns

Net – Stiff, very-open-weave – Ballet skits & veils

Pellon – Non-woven stiffening material - petticoats

Sateen – Satin-weave lining material

Satin – High-luster satin-weave – evening gowns to draperies

Taffeta – Used extensively in 18th & 19th century gowns

Moiré taffeta – Taffeta with a nonrepetitive pattern pressed into the surface

Velour – Pile-weave fabric – Heavy weight (upholstery & drapes) Light weight

(sportswear)

Velvet – Drapes well, lustrous – evening gowns to capes

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Fabrics Finishes

Functional Finishes

1.Permanent-press – reduces wrinkles in fabric and puts in permanent creases

2.Mercerization – adds strength & shine to cotton thread

3.Flameproofing – chemical process – prevents cloth from supporting flames

4.Preshrunken – has been bathed in water

5.Anti-bacterial agents – reduces stains from natural substances such as sweat

Decorative Finishes

Alter the appearance of the fabric – bleaching, dyeing, printing, texturing…

Finishes are applied to fabric before they leave the mill although some

finishes are applied in costume shops!

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Nonfabric Materials

Leather

Used for hats, shoes, & period pieces such as vests, armor, and belts

Usually treated cowhide (in U.S.)

Smooth & rough side

Can be dyed & stitched

Tools for leather working – awls, leather punches, etc.

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Nonfabric Materials

Sculptural Arts Coatings

Made in North Caroline – water-based, low-emissivity craft products,

paints, & finishes - bonds materials together to create anything needed!

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Nonfabric Materials

Plaster Bandage

Plaster-impregnated gauze – make items from forms such as masks,

small armor pieces, etc.

Same material used to make casts

Water soluble – no toxic or noxious fumes – forms easily

Once dry, can be sanded or painted

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Nonfabric Materials

Thermoplastics

Stiff plastics that soften in hot water to then be molded

Pellet, mesh, and fabric forms

Masks, armor, etc.

Can be finished with most paints

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Nonfabric Materials

Fiberglass

2 Forms:

1.Glass fibers in form of mat or woven cloth

2.Resin coat that cures into hard plastic

Used to make armor and helmets

Resin can be used alone in production of jewelry

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Nonfabric Materials

Metal

Aluminum, copper, and brass

appliqués and jewelry are

often used in construction

of bodices, gowns, armor,

buckles, etc.

Metals are often attached

using pop rivets or special

adhesives…

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Garment construction

Theatre costumes vs. the garment industry

Single, perfect fit version vs. multiple copies of one garment

Built to last for production vs. built to last as long as possible

Costume design is geared around creating character – not

creating a ‘saleable’ garment

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Garment Construction: Patterns

Patterns

3 Main goals…

1.Manipulate a flat piece of cloth by cutting and shaping so it conforms to a

specific three-dimensional body

2.Accurately translating the costume designer’s rendering

3.Creating a costume that serves the needs of the script, actor, production,

etc.

2 Main methods…

1.Flat patterning (drafting)

2.Draping

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Garment Construction: Patterns

Flat Patterning

Get actor measurements

Use measurements to develop basic pattern – a.k.a. the body block / block

Transfer paper pattern to muslin and stitch garment together

Actor comes in for fittings – Adjustments are made

Costume pattern developed from the modified block

Muslin mock-up fitted to the actor for more adjustments

Construct final garment

Final fittings for performer

Cutter of the pattern must be familiar with the designer’s concepts as

well as historical patterns for clothing –

has to be able to translate research into practical application

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Garment Construction: Patterns

Actor Measurements

Measurements include:

Traditional clothes sizing

Specific measurements that involve various

segments of the performer’s body –

Arm length to wrist

Bicep

Armseye

Underbust to waist

Etc. – See book pg. 439!

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Garment Construction: Patterns

Draping

Process of pinning fabric directly to the tailor’s form and creating

pattern pieces or a garment by manipulating the fabric until the

desired look is achieved

Requires a dress form that is padded/altered to match the

performer’s exact measurements

Traditionally used to create non-tailored elements

Sometimes creates a mock version but often works to build the

garment without mock version as fabric drape is essential to this

type of creation process

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Garment Construction: Patterns

Pattern-Drafting Software

With computers, cutters can use software to develop patterns

Cannot be used for draping

Learning curve with the software – cutter must know how to really

use the software for it to be useful!

Sample software: Custom Pattern Maker

Requires a plotter to print adequately

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Special-Effects Treatment of Fabrics

Fabric Dyeing

Safety 1st! Look at the MSDS information to be sure you are handling

any and all materials correctly!

Types of dyes must know setting agent as well as time, saturation, &

heat needs

Union Dyes – Household dyes such as RIT – made to be moderately

effective – not particularly effective on synthetic materials

Aniline Dyes – a.k.a. unified aniline dyes or acid dyes – Strong colors w/ light

to full saturation – good with natural fibers & some synthetics

Disperse Dyes – Intense colors – almost colorfast if dyed when dye is at

boiling point – designed for use with synthetics

Fiber-Reactive Dyes – Most useful for fabric painting with natural fibers –

Uses cool or lukewarm water

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Special-Effects Treatment of Fabrics

Fabric Painting

Painted to add texture / enhance 3D qualities /

Age Fabric / Create or reinforce a pattern

Fabric painting can be done with a

variety of materials

– dyes, fabric paints, spray enamels, French enamel varnish,

shellac, bronzing powders, etc. –

and a variety of applicators

– brushes, sponges, spray guns, air brushes, stencils,

hot glue guns, etc. –

Read MSDS to make certain you know safety procedures for application

and later treatment of the garment!!!

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Special-Effects Treatment of Fabrics

Costume Aging

Sometimes, it is necessary to distress a garment

– showing its age, abuse, and wear-and-tear

Distress appears where fabric receives greatest stress

– elbows, knees, seat, etc.

Distress can be created by overstretching a garment, painting it, ripping

or shredding the fabric…

Experience is the best teacher! Experiment!!!

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Wigs…

Allows designer to achieve correct hair style – especially important with

period costuming

Rent or make – wigmaking is a difficult craft!

Restyle contemporary wigs to look like period is also a low-cost

alternative

To make a commercial wig appear more natural, 1/3 of the hair is

removed and is then used to ventilate a piece of netting attached to

the wig’s foundation – this creates a more realistic hairline…

Also hair extensions and pieces are used to supplement a performer’s

natural hair

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Wigs…

Some period styles that

require the use of wigs,

extensions, or pieces to

create…

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Millinery…

Hats often provide the completing

element for period costume…

Many hats can be created from a

basic broad-brimmed, deepcrowned felt hat

Steaming allows hats to be shaped

and molded as needed – using a

hat mold or hat block…

Also buckram is used to help create

hats

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Millinery…

Some period styles that

require hats or headpieces

to complete the ‘look’ of

the particular period…

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Footwear…

Appropriate footwear makes a costume complete…

Ideal solution is to contract with a cobbler or shoe company but that is

not cost effective

Usually shops add elements to existing shoes to create the illusion of a

period piece

Soft- and hard-soled house slippers are a common base for building

shoes – usually leather additions and other accessories provide the

rest of the illusion…

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Footwear…

A progression of footwear styles over the course of history…

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Jewelry…

Simplicity and exaggeration combine to create stage jewelry…

Know your research to create something that looks correct

Wood, plastics, metals, and more can be used to create jewelry

Attaching cording and trim, painting the object, and applying rhinestones

adds to the illusion

All shops should have a collection of ‘junk jewelry’ – rings, brooches,

necklaces, and similar pieces that look gaudy up close often look rich

and elegant from stage…

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Armor…

Breastplates and helmets are often made from Fabric Form, fiberglass,

thermoplastics, leather, etc.

Most armor requires a form or armature that is made of clay & wire…

The form is covered with foil or some other no-stick material…

The material making the armor is applied to that, making a rigid shell

Then apply decoration to suit the character

If using thermoplastics, insulate the actor and mold directly on the body

to ensure a good fit…

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Masks…

Another major element of design, masks can be

made in a variety of ways…

Papier-mâché – plaster bandages – Fabric

Form – fiberglass – Thermoplastics…

Often, molds are made of the performer’s face

and then the mask is formed from that ‘cast’

Once built, masks are decorated and/or painted

to express character as needed

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.

Chapter 17: Costume Construction

Accessory Construction

Masks…

Papier-mâché process

1

1.Life-mask made and

covered with aluminum

foil

2

2.Apply glue-soaked strips

of paper to mask

3.Allow to dry for 24-48 hrs.

4.Finish as desired

3

4

Theatrical Design and Production

© 2006 McGraw-Hill. All right reserved.