What Is Supply Chain Management?

advertisement

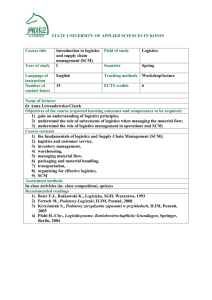

What Is Supply Chain Management? Adriano O. Solis, Ph.D. Academic Advisor, NAPM El Paso The past couple of decades have seen much attention given to supply chain management (SCM). The term was first introduced by consultants in the 1980s, and its definition has undergone some fairly significant evolution since then. The fierce competition in global markets, increasingly shorter product life cycles, and increasingly higher customer expectations with respect to product capability and reliability, delivery lead times, flexibility, and service have all led business firms to focus on their supply chains. In an industrial setting, the supply chain [see Figure 1] encompasses all activities associated with the flow and transformation of goods and services, as well as the attendant information flows, from suppliers of raw material and components, through manufacturing/assembly plants, through the distribution chain (transporters, warehouses, distribution centers, retailers), and down to the customers/end users. Managing the supply chain involves transcending the traditional, legal boundaries of entities along that chain—such as between the manufacturer and its suppliers, or between the manufacturer and its distributors. Figure 1. Suppliers’ Suppliers Suppliers Supply Chain: Entities and Flows Manufacturers Warehouses, Distribution Centers, Transporters Retailers Customers/ Endusers Solid bi-directional arrows represent material flows. Backward flows may refer to returns of products/materials. Dotted bi-directional arrows represent information flows. The early literature (e.g., Jones and Riley, 1985) defined SCM as the planning and control of total materials flow from suppliers through customers. Later literature referred to the management not only of the materials flow, but of both materials and information flows. However, there had been some confusion between SCM and logistics. Until recently, SCM was generally understood by practitioners, consultants, and academics to be the integration of logistics across the supply chain, inclusive of customers and suppliers (Lambert and Cooper, 2000). This understanding had largely been consistent with the definition of logistics management appearing in previous literature [circa 1986] of the Council of Logistics Management (CLM): Article in The Criterion, April 2001 [Newsletter of the El Paso affiliate of the National Association of Purchasing Management] “The process of planning, implementing, and controlling the efficient, cost-effective flow and storage of raw materials, in-process inventory, finished goods, and related information flow from point-of-origin to point-of-consumption for the purpose of conforming to customer requirements.” The CLM eventually issued in October 1998 a revised definition explicitly stating the position that logistics management is only a part of SCM: “Logistics is that part of the supply chain process that plans, implements, and controls the efficient, effective flow and storage of goods, services, and related information from the point-of-origin to the point-of-consumption in order to meet customers’ requirements.” SCM, therefore, is not just another name for logistics, but involves elements that extend beyond logistics (Cooper, Lambert, and Pagh, 1997). The Supply-Chain Council—which was organized in 1996-1997 by representatives of a number of companies including, among others, Procter & Gamble, Lockheed Martin, Texas Instruments, Compaq, and Bayer (see www.supply-chain.org)—defines the supply chain as encompassing “every effort involved in producing and delivering a final product or service, from the supplier’s supplier to the customer’s customer.” Accordingly, the Supply-Chain Council emphasizes that SCM includes key business processes such as supply and demand management, sourcing of raw materials and parts, manufacturing and assembly, tracking of warehousing and inventory, order entry and management, distribution across all channels, and delivery to the customer. On the other hand, the Global Supply Chain Forum (GSCF)—a group of practitioners and academic researchers which has been meeting since 1994, and whose stated objective is to improve the theory and practice of supply chain management—defines SCM as “the integration of key business processes from end user through original suppliers that provides products, services, and information that add value for customers and other stakeholders.” The key supply chain processes identified by the GSCF are: (a) customer relationship management, (b) customer service management, (c) demand management, (d) order fulfillment, (e) manufacturing flow management, (f) procurement, (g) product development and commercialization, and (h) returns (Lambert and Cooper, 2000). Definitions do vary from one source to another in terms of exact wordings. Nevertheless, the understanding of SCM has gone beyond merely integrating logistics across the supply chain. SCM is currently understood in terms of integrating and managing the key business processes associated with the flow and transformation of goods and services, as well as the attendant information flows, both within and between the various organizations along the supply chain (e.g., Lambert and Cooper, 2000; Ballou et al., 2000). As cited in early literature (Jones and Riley, 1985; Houlihan, 1985), the stated goal of SCM is to meet customer service objectives, while at the same time minimizing inventory and related costs. Underlying this goal has been the need to boost competitiveness and profitability in increasingly tougher global markets. This rationale continues to be as relevant today as it had been when SCM was first being discussed in the 1980s. Current literature would refer to the supply chain as consisting of all stages involved, directly or indirectly, in fulfilling a customer request (e.g., Chopra and Meindl, 2001) and SCM as involving the Article in The Criterion, April 2001 [Newsletter of the El Paso affiliate of the National Association of Purchasing Management] 2 integration of all activities along a supply chain to achieve a sustainable competitive advantage, minimize system-wide costs, satisfy service level requirements, and/or maximize the overall value generated (Handfield and Nichols, 1999; Simchi-Levi et al., 2000; Shapiro, 2001; Chopra and Meindl, 2001). The value generated by the supply chain—which refers to the difference between what the final product is worth to the customer and the effort expended in fulfilling the customer’s request—would be correlated with the profitability of the supply chain. Apparently, while goals and objectives of SCM are stated somewhat differently in various sources, they all lead back to the same rationale for SCM as declared early on. References Ballou, R.L., Gilbert, S.M., and Mukherjee, A. (2000). New Managerial Challenges from Supply Chain Opportunities. Industrial Marketing Management, Vol. 29, No. 1, 7-18. Chopra, S. and Meindl, P. (2001). Supply Chain Management: Strategy, Planning, and Operation, PrenticeHall, Upper Saddle River, N.J. Cooper, M., Lambert, D.M., and Pagh, J.D. (1997). Supply Chain Management: More Than a New Name for Logistics. The International Journal of Logistics Management, Vol. 8, No. 1, 1-14. Handfield, R.B. and E.L. Nichols, E.L., Jr. (1999). Introduction to Supply Chain Management, Prentice-Hall, Upper Saddle River, N.J. Houlihan, J.B. (1985). International Supply Chain Management. International Journal of Physical Distribution and Materials Management, Vol. 15, No. 1, 22-38. Jones, T.C. and Riley, D.W. (1985). Using Inventory for Competitive Advantage through Supply Chain Management. International Journal of Physical Distribution and Materials Management, Vol. 15, No. 5, 16-26. Lambert, D.M. and Cooper, M.C. (2000). Issues in Supply Chain Management. Industrial Marketing Management, Vol. 29, No. 1, 65-83. Shapiro, J. (2001). Modeling the Supply Chain, Duxbury, Pacific Grove, CA. Simchi-Levi, D., Kaminsky, P. and E. Simchi-Levi, E. (2000). Designing and Managing the Supply Chain: Concepts, Strategies, and Case Studies, McGraw-Hill, New York. Notes: 1. This is the first in a series of short, expository articles on supply chain management. These have been incorporated as sections in an article—forthcoming in the Encyclopedia of Information Systems—on supply chain management and information technology prepared by Professors Mo Adam Mahmood, Leopoldo A. Gemoets, and Adriano O. Solis, all of the Department of Information and Decision Sciences, The University of Texas at El Paso. 2. From March 5 through April 11, 2001, members of the National Association of Purchasing Management (NAPM) have the opportunity to vote on the proposed renaming of NAPM to the Institute for Supply Management (ISM). The current District II of NAPM, with which NAPM-El Paso is affiliated, will be referred to as the Southwest Supply Chain Forum. 3. NAPM publishes The Journal of Supply Chain Management (formerly the International Journal of Purchasing and Materials Management), sub-titled A Global Review of Purchasing and Supply. The latest issue of The Journal of Supply Chain Management (Volume 37, No. 1, Winter 2001) includes the following articles: o Deeter-Schmelz, D.R., Bizzari, A., Graham, R., and Howdyshell C. Business-to-Business Online Purchasing: Suppliers’ Impact on Buyers’ Adoption and Usage Intent. o Ramcharran, H. Inter-Firm Linkages and Profitability in the Automobile Industry: The Implications for Supply Chain Management. o Heriot, K.C. and Kulkarni, S.P. The Use of Intermediate Sourcing Strategies. o Nellore, R. The Impact of Supplier Visions on Product Development. o Shah, J. and Singh, N. Benchmarking Internal Supply Chain Performance: Development of a Framework. Article in The Criterion, April 2001 [Newsletter of the El Paso affiliate of the National Association of Purchasing Management] 3