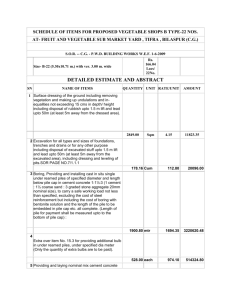

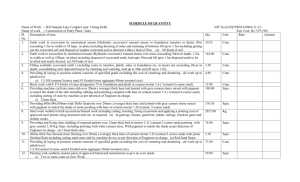

EBDescr

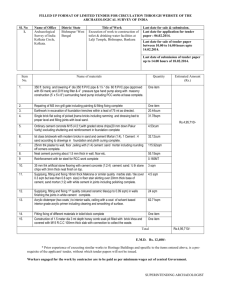

advertisement