ES442 - Project 2

advertisement

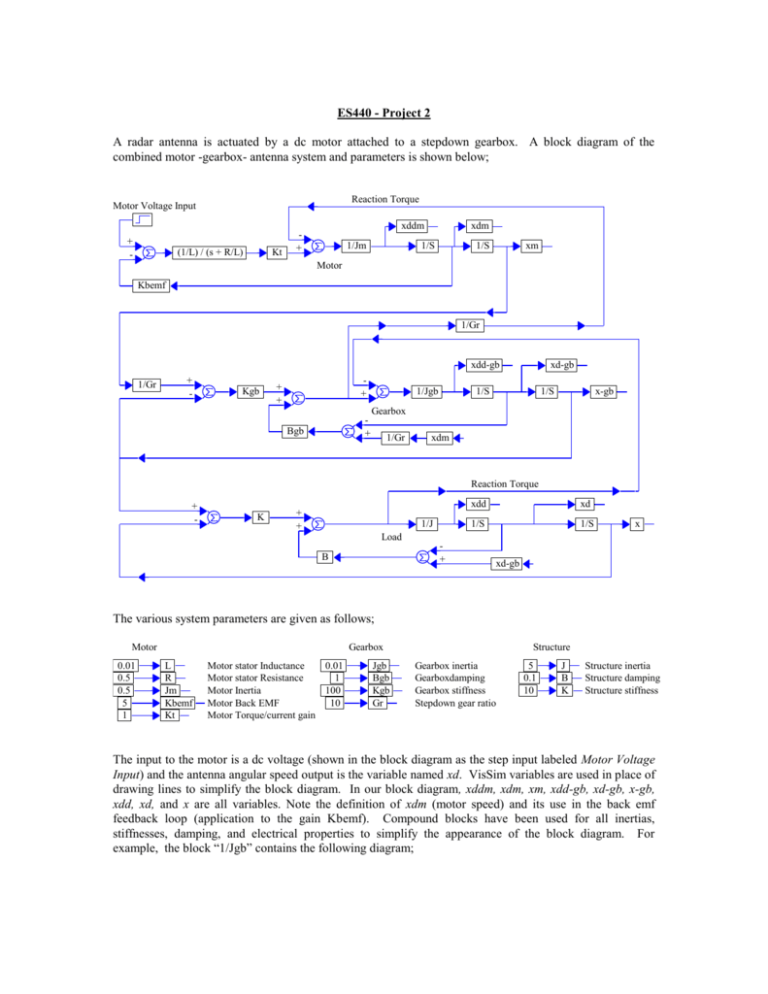

ES440 - Project 2 A radar antenna is actuated by a dc motor attached to a stepdown gearbox. A block diagram of the combined motor -gearbox- antenna system and parameters is shown below; Reaction Torque Motor Voltage Input + - (1/L) / (s + R/L) Kt xddm + 1/Jm xdm 1/S 1/S xm Motor Kbemf 1/Gr xdd-gb 1/Gr + - Kgb + + + + Bgb 1/Jgb xd-gb 1/S 1/S x-gb Gearbox 1/Gr xdm Reaction Torque + - K + + 1/J xdd xd 1/S 1/S x Load + B xd-gb The various system parameters are given as follows; Motor 0.01 0.5 0.5 5 1 Gearbox L R Jm Kbemf Kt Motor stator Inductance 0.01 Motor stator Resistance 1 Motor Inertia 100 Motor Back EMF 10 Motor Torque/current gain Jgb Bgb Kgb Gr Structure Gearbox inertia Gearboxdamping Gearbox stiffness Stepdown gear ratio 5 0.1 10 J B K Structure inertia Structure damping Structure stiffness The input to the motor is a dc voltage (shown in the block diagram as the step input labeled Motor Voltage Input) and the antenna angular speed output is the variable named xd. VisSim variables are used in place of drawing lines to simplify the block diagram. In our block diagram, xddm, xdm, xm, xdd-gb, xd-gb, x-gb, xdd, xd, and x are all variables. Note the definition of xdm (motor speed) and its use in the back emf feedback loop (application to the gain Kbemf). Compound blocks have been used for all inertias, stiffnesses, damping, and electrical properties to simplify the appearance of the block diagram. For example, the block “1/Jgb” contains the following diagram; Where “Jgb” is the variable defined to be the gearbox inertia. Other compound blocks in the diagram are constructed similarly. Section I: 1. Compute the transfer function of xd / Motor Voltage Input analytically (using block diagram manipulations) showing all work. Hint: the closed loop transfer function, zeros, and poles should be; T ( s) 40 s 3 200 s 2 10000 s s 7 160.04 s 6 17508.2 s 5 660770.1s 4 11048008s 3 1500200 s 2 20000000 s Zeros: 0 100 100 Poles: 0 55.01 j 89.309 24.995 j19.361 1.364e 2 j1.348 2. Check your transfer function by first coding the model in VisSim and then numerically obtain the transfer function (analyze…transfer function info). Use the following simulation information: Range Start = 0, Step Size = . 0.0025, Range End = 25, Integration Algorithm = Runge Kutta 4th order. 3. What are the poles, zeros, DC gain (you may use vissim for this). 4. Derive an approximate second order transfer function with the correct DC gain using the approximating method outlined in class. You may use a damping ratio of 0 for this approximation. 5. Compare the results of the true and approximate transfer function by applying a unit step input to each (in VisSim) and plot the xd outputs on one plot. Use the following simulation information: Range Start = 0, Step Size = . 0.0025, Range End = 25, Integration Algorithm = Runge Kutta 4th order. Section II: .0363 , you will design and test (via simulation) a s 1.817 feedback controller which will achieve the following design specifications: Using the approximate transfer function: G ( s) 1. 2. 3. 4. 2 System is stable Steady State Unit Step Error = 0 Steady State Unit Ramp Error <= 0.4 Damping Ratio >=0.5 5. Settling Time < 12 seconds After the controller has been designed and tested on the approximate transfer function you will compare its performance (via simulation) on the actual full order system from Section I. The controller is designed in two steps; (1) an inner loop and (2) an outer loop. The purpose of the inner loop controller is to modify the transient response of the plant using a cascade lead compensator to move the plant poles leftward making the inner loop feedback system faster and more stable. To the outer loop, the closed inner loop will look like a gain over the frequency range of the outer loop. The outer loop controller, consisting of an integral control, will slightly modify the transient response of the closed inner loop, but more importantly, will satisfy the two steady state error specifications (and maintain stability). Perform the following steps, hand in all hand calculations, sketches, and computer results. s 4.8 , in cascade with the G (s) in the s 100 forward loop. Use a Root Locus sketch to design K Lead such that the dominant closed loop poles lie near s1,2 5.29 j 5.26 . What is K Lead ? What are the resulting closed loop poles and zeros for the inner loop? 1. Add a lead compensator of the form, GLead (s) K Lead 20.8 2. Code the closed inner loop in VisSim (using the approximate transfer function) and simulate it using a stepsize of .0025, range end of 5 seconds and RK2 integration. These values will be used for the remaining steps of the project. Plot the unit step response, unit ramp response, steady state unit step error and the steady state unit ramp error. 3. K Add an integral compensator of the form, G int (s) int , in cascade with the closed inner loop. Find s K int using a root locus sketch to place the dominant closed loop poles to satisfy the settling time specification and the steady state ramp error specification. Your K int value should produce a dominant pole pair near s1,2 4 j 7 with a damping of just under 0.5. What are the resulting closed loop poles and zeros for the closed outer loop? What is the steady state step error coefficient and the steady state ramp error coefficient? 4. Code the closed outer loop in VisSim around the closed inner loop from part 2 and simulate it using a stepsize of .0025, range end of 5 seconds and RK2 integrator. Plot the unit step response, unit ramp response, steady state unit step error and the steady state unit ramp error. How do the error values relate to the coefficient calculations made in part 3? 5. Implement the controller (both inner and outer loops) on the original high order system (Section I) and compare unit step responses between it and the reduced order (design) system. Plot the steady state step and ramp errors also. Comment on differences in the responses.