MEC316 L2 - Pressure Velocity Measurements

MEC316 Lab#2

Pressure-Velocity Measurements

Group #9:

Kanchan Bhattacharyya – Writer; Synthesizing Paper

Matthew Stevens – Graphs & Error Analysis

Ting Zhang – Materials & Methods

Xie Zheng – Experimental Procedure

A. Abstract

The general goal of this experiment is firstly to learn how to calibrate an instrument with respect to a reference standard – our experiment being one instance

of this by trying to calibrate a variable reluctance pressure transducer using an inclined manometer as the pressure standard. The purpose of calibrating an instrument is to ensure clear, distinguishable, load-free readings in a response to the range of inputs provided. For our experiment, this would mean to have clear and distinct output voltage readings that do not exceed the capacity of the DAQ to read, over the expected range of pressure differences created from varying the state of the air flow baffle. In a sense, by normalizing our read-out over the range we want to study and not beyond, we ensure that we get the best response from our instruments. In this experiment, this is achieved by setting a maximum allowable voltage of 5 volts and assigning that to a maximum expected pressure difference of

4 inches as measured by the inclined manometer, then taking 0.25 inch pressure increments and recording output voltages over the whole expected range of pressures, and using that data to determine a least squares linear regression curve whose slope is the calibration constant “C” or “1/k” where “k” is the static sensitivity, which will correlate all measured output voltages to inferable pressure differences from that point on in the experiment.

The second goal in this experiment is compare the result of the Bernoulli equation in describing flow velocity to the more simplified result of the Conservation of Mass Principle and draw some conclusions. The result from the Bernoulli

Equation states that Pstag (Total Pressure) = Pstatic + Pdynamic and thus by taking several measurements of stagnation & static pressure across the longitudinal range of the test section, it is possible to deduce velocity as a function of channel position.

This can then be compared to the result obtained from a Conservation of Mass

(CoM) approach which under assumptions of negligible changes in density, becomes the Continuity Equation A1V1 = A2V2, in other words the gain in the output velocity V2 is equal to the ratio of A1:A2. Of course, the second approach only takes the experimental inlet velocity and determines how it varies as a function of pure geometry. Thus, boundary layer effects and the bulk of experimental data which the

Bernoulli approach requires in calculating velocity, are ignored in the CoM approach which results to higher predicted velocities in its graph when compared to Bern oulli’s which we determined to be the more accurate method.

B. Introduction

Pressure – Velocity measurements such as the ones conducted in this experiment are a standard tool in fluid mechanics and studying flows of varying channel widths and mean velocities which may be laminar or turbulent and require different cost functions to model appropriately.

Mapping out the pressure & velocity over the length of a test section as well as the width can give us a sense of the shape of the velocity profile, whether or not the flow is 1D, 2D, or even higher, and predict turbulence effects. This kind of an analysis might be useful for people doing small scale similitude and modeling of boats or planes. By scaling down the size of the model and also the pressures and velocities of the air flow (not necessarily a linear scale), it would then be important to test whether or not the flow which the model will be tested in is a good representation of the flow the full sized boat or plane will experience in its environment.

In this experiment, pressure-velocity measurements were used to compare the Bernoulli model ’s results for how velocity should vary with channel position in a

test section of varying cross sectional area with the result from the Conservation of

Mass, more specifically Continuity. Both take into consideration that due to the geometry of the test section, fluid flow velocity must adjust to the cross sectional area. However, Bernoulli goes one step further and states Pstag (Total Pressure) =

Pstatic + Pdynamic (0.5*row*v^2) is a constant and if the fluid flow velocity is to change according to the geometry, it must also satisfy this relation as well.

What makes it possible to verify between these two approaches for describing velocity as a function of channel position are the experimental results obtained from our pressure-velocity measurements and comparing our graphs and seeing which one takes into consideration real-world effects like wall shear stress leading to parabolic flow, boundary layer effects, the fact that for compressible gases and depending on the test section, A1V1 = A2V2 may not hold we may have to realize that it is actually P1A1V1 = P2A2V2 (where P = density), where a density term exists as well, and so on. In short, these sorts of tests have a real consequence for testing out theories regarding certain types of flows for given channel widths and channel speeds, determining the existence of turbulence and such. For us it was simply comparing Continuity with Bernoulli but this could be applied to more complex models of flow.

C1. Theory ( Calibration of a Variable Reluctance Pressure Transducer)

A variable reluctance pressure transducer will be calibrated against an inclined manometer. A pressure difference between two pressures, P1 and P2, is applied to both the inclined manometer and a diaphragm pressure transducer system. The output of the calibrated inclined manometer is the pressure difference P2-P1, which can be read directly using the inclined scale (in units of inches of water). The output

(in volts) of the transducer system is then calibrated against the inclined manometer readings.

The static property of the pressure transducer system is described by the following equation

E=k(P2-P1), (2.1)

Where

e= voltage output of the transducer system [volt]

k=static sensitivity [volt m^2/N]

The calibration curve is given by

P2-P1=Ce,

Where C=1/k is the calibration factor. [Note: P2 is the pressure on the ‘+’ side of the transducer and P1 is the pressure on the ‘-’ side.]

We are using the diaphragm pressure transducer combined with a combined with a demodulator to convert flow pressure to an electrical signal. This analog signal is the input signal to the computer-supported data acquisition unit. The calibration factor, C, of this transducer system is needed to calculate the pressure difference P2-P1 from a measurement of the sensor voltage e.

The static sensitivity is an important characteristic of a diaphragm transducer system. It is one the basic engineering techniques to find and change the sensitivity.

The sensitivity of the transducer is obtained by relating the input and output of the transducer system.

C2 Theory (

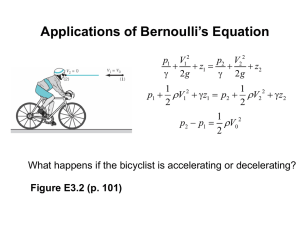

Bernoulli’s Equation Applied To Convergent-Divergent Passage)

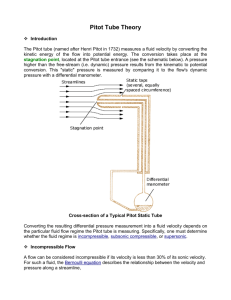

This experiment demonstrates the use of a Pitot tube, and investigates the application of Bernoulli’s theorem to flow along a convergent-divergent passage

(Fig.2-2).

Along a streamline (assuming negligible frictional losses) the total pressure, Pt, is constant. Thus at any points along the streamline we have

Pt=P1+1/2ρ(v1)^2+ρg(z1)=P2+1/2ρ(V2)^2+ρg(z2) (2.3)

Here Pi is the static (thermodynamic) pressure at position i (i.e., it is the pressure that you would measure if your sensor moved with the flow); Vi is the speed of the flow at position I, zi is the elevation at position I, ρ is the fluid mass density, and g is the local gravitational acceleration. If the Pitot tube does not significantly alter the flow then the static pressure is the pressure sensed at the ‘static’ tap on the side of the Pitot tube; we will label this pressure P-static.

The stagnation pressure P-stag, is the pressure the fluid velocity was reduced to zero, that is P-stag=Pt (at V=0). Since the flow velocity is zero at the tip of the

‘stagnation’ tap of the Pitot tube. Thus, using Eq.(2.3) we have

P-stag=Pstatic+1/2ρV^2

Where P-stag is the pressure the fluid would have if the flow velocity was reduced to zero, that us P-stag=Pt (at V=0 ). Since the flow velocity is zero at the top of the Pitot tube(the stagnation tap) the total pressure can be determined by observing the pressure at the ‘stagnation’ tap of the Pitot tube. Thus, we have

P-stag=Pstatic+1/2ρV^2 (2.4)

D. List of Equipment and Experimental Procedure

D.1 List of Equipment:

Variable Reluctance Pressure

Transducer

Air-Flow Bench (AF10), Pitot

Tube

Inclined Manometer

Sine-Wave Carrier

Demodulator (Model CD 15)

National Instruments Data

Acquisition System (NI USB-

6008)

D.2 – Experimental Procedure

Part I: Calibration of a Variable Reluctance Pressure Transducer

a) Check to make sure the equipments are configured as shown in Fig. 2-1 (the equipments are already set up in the laboratory) and check all connections. b) Turn the demodulator power on and set ‘zero’ to make the output as close to zero as possible (by using a voltmeter, the initial voltage reading is pretty close to zero). Leave the voltmeter open to try to make the temperature of resistors inside at the same level. Therefore, the error due to voltmeter could be minimized. Record the location of the meniscus of the inclined manometer; this reading becomes the ‘zero’ of the manometer scale. Turn on the computer. c) Close the flow baffle of the channel and then turn on the fan. Here, the reading on the meniscus is 1.9 (inches). The velocity of flow is increased by slightly opening the flow baffle. Stop moving the flow baffle until P2-P1=~4 inches of water when the reading becomes 5.9 (inches) which we counted as the maximum pressure difference used in the experiment. Then check the output of the transducer and adjust the ‘span’ of the demodulator if necessary - the reading was also pretty close to 5 volts, so there was no need to adjust the demodulator. d) Close the baffle and turn off the fan. Make sure connection of the positive output line of the demodulator to analog-input channel 1 of the data acquisition terminal board; connection of the negative output li ne to ‘AIGND’. e) Start the data acquisition program by loading WINDOWS, select exp2.vi in the

\labview directory. f) Record the ambient pressure, P1, which is 1.9 inches and position the stagnation tap of the pitot tube at the inlet of the channel. f) Turn on the fan. Adjust the air flow baffle to make the increments of P2-P1 is about 0.25 inches over the range [0,4]. And record “e” for difference values of

P2-P1 by clicking on the run icon on the tool bar on computer. After repeating the steps for 16 times, here, we get 16 sets of the data for P2-P1 and also the voltage, e. During the procedure, hold bottom of the pitot tube to prevent the tip from vibrating. g) Close the flow baffle and turn off the fan.

Part II: Bernoulli’s Equation Applied To A Convergent-Divergent Passage a) Use the setup from Part I of the experiment and make sure all equipment is in the initial condition. b) Connect the stagnation pressure output from the pitot tube to the diaphragm transducer and the inclined manometer. Record the initial reading for the inclined manometer (Po=1.9 inches). Turn on the fan and slowly open the baffle until the pressure difference is about 1 inch of water and the reading is 2.9 inches. Then leave the baffle at that position. c) Start to record the channel position Di of the static tap which lined up with the ruler scalar on the pitot tube and the transducer output at 25 positions which

start from 10cm to 250cm throughout the passage (here, we have 25 sets of data with increments of 10cm over the range [10,250]). For recording the transducer output, clicking the run icon on the tool bar on computer to get the data. Repeat the step until the position of static tap is lined up with the scale at

250cm. d) Disconnect the stagnation pressure output and switch the connection of plastic tube to the static pressure output from the pitot tube. The plastic tube connects the transducer and the inclined manometer. e) Put the pitot tube back to the original position (where the static tap lined up with the ruler scalar at 10cm). Record the transducer output by clicking the run icon on the tool bar on computer. Then, still make the increments of 10cm and move down the Pitot tube to the position of the static tap on the Pitot tube is at each of the positions used in step c. Repeat the step until the position of static tap is lined up with ruler scalar at 250cm. Close the flow battle and turn off the fan.

E. Results & Discussion

Part I: Calibration of a Variable Reluctance Pressure Transducer (VRPT)

Table 1: Calibration of VRPT (Scaling 4” Pressure to 5 Volts) Using Inclined

Manometer & Data For Calculating Calibration Factor & Static Sensitivity

Trial

(i)

Position

(inches) ∑∆z (inches) ∑∆z (meters)

∆P =

ρg∆z

(N/m 2 )

Diaphragm

Transducer

Output

Voltage

(Volts)

1

2

3

4

1.90

2.15

2.40

2.65

0.00

0.25

0.50

0.75

0.0000

0.0064

0.0127

0.0191

0.0000

62.2935

124.5870

186.8805

0.0000

0.2926

0.6341

0.9672

8

9

10

11

12

5

6

7

2.90

3.15

3.40

3.65

3.90

4.15

4.40

4.65

1.00

1.25

1.50

1.75

2.00

2.25

2.50

2.75

0.0254

0.0318

0.0381

0.0445

0.0508

0.0572

0.0635

0.0699

249.1740

311.4675

373.7610

436.0545

498.3480

560.6415

622.9350

685.2285

1.3000

1.5780

1.9230

2.2410

2.5490

2.8590

3.1730

3.4810

13

14

15

16

4.90

5.15

5.40

5.65

3.00

3.25

3.50

3.75

0.0762

0.0826

0.0889

0.0953

747.5220

809.8155

872.1090

934.4025

3.8100

4.1300

4.4340

4.7270

17 5.90 4.00 0.1016 996.6960 5.0900

Caption: This table reflects the process by which the VRPT was calibrated such that at the highest expected pressure achieved in this experiment, the output voltage would not exceed the 5 volt limit of the DAQ. As shown in Columns 2 & 3, 0.25” increment pressure readings are taken along the scale of the inclined manometer as the baffle was opened to reach a maximum of a 4”. This was then set to 5 volts using the ‘span’ of the demodulator to calibrate the VRPT for the range of the experiment.

As shown in Columns 4 & 5 it is simple to convert “pressure (in.)” of the inclined manometer to “pressure (N/m^2)” which when graphed with respect to output voltage, can provide an estimate for “C”, the calibration factor through least squares linear regression. This conversion also helps in Part II, where having a calibration curve with “pressure (N/m^2)” makes calculating velocity from dynamic pressure using

Bernoulli’s Equation quick with consistent pressure units.

Table 2: Least Squares Linear Regression Fit; Calculation of Static Sensitivity “K”,

Calibration Factor “C”, & Respective Uncertainties

6

7

8

9

1

2

3

4

5

Linear Regression

Analysis

Solving for C

Trial

(i)

Diaphragm

Transducer

Output

Voltage

(Volts)

10

11

12

13

0.0000

0.2926

0.6341

0.9672

1.3000

1.5780

1.9230

2.2410

2.5490

2.8590

3.1730

3.4810

3.8100

∆P = ρg∆z

(N/m 2 )

0.0000

62.2935

124.5870

186.8805

249.1740

311.4675

373.7610

436.0545

498.3480

560.6415

622.9350

685.2285

747.5220 x i y i

0.0000

18.2271 x i x i a + bx i

0.0000 -1.2066

0.0856 56.3287

79.0006 0.4021 123.4793

180.7508 0.9355 188.9783

323.9262 1.6900 254.4183 27.5023

491.4957 2.4901 309.0827

718.7424 3.6979 376.9216

1602.8740 8.1739 560.9714

1976.5728 10.0679 622.7147

2385.2804 12.1174 683.2781

2848.0588 14.5161 747.9709 b = C

(y i

- [a +bx i

]) 2

1.4559

35.5793

1.2269

4.4008

5.6875

9.9891

977.1981 5.0221 439.4513 11.5384

1270.2891 6.4974 500.0148 2.7781

0.1089

0.0485

3.8040

0.2015

14

15

16

17

4.1300

4.4340

4.7270

5.0900

809.8155

872.1090

934.4025

996.6960

3344.5380

3866.9313

4416.9206

5073.1826

17.0569

19.6604

22.3445

25.9081

810.8939

870.6708

928.2847

999.6630

Captions: Columns 2 & 3 show the voltages & pressures to be correlated through the linear fit. Columns 4 through 7 show data which will be summed in the table below and used calculate “a” and “b” coefficients of linear regression curve.

1.1629

2.0685

37.4276

8.8032 k Sx Sy Sxy Sxx

17 43.1889 8471.9160 29573.9886 150.6658

Caption: Displays values for the summation of all ‘x’ quantities (voltage), the summation of all ‘y’ quantities (∆P), and the summation of relevant products used to determine “a” and “b” of linear regression curve.

Uncertainty in

C a b = C (N/m 2 ∙V) k = 1/C

(V∙m 2 /N) theta u a u b

-

1.2066 196.6345 0.0051 153.7832 1.4897

Caption: Final y-intercept “a” and slope “b” values tabulated, “k” calculated as

0.5004 inverse of “b”, the latter being the calibration factor “C”. Error function theta is also calculated as well as “Ua” the uncertainty in the y-intercept and “Ub” the uncertainty in the calibration factor “C”.

Graph 1: Best Fit Linear Regression Curve – “C” Calculation

Best Fit Linear Regression Curve - "C" Calculation

1200.0000

1000.0000

800.0000

600.0000

y = 196.63x - 1.2066

400.0000

200.0000

0.0000

0.0000

-200.0000

1.0000

2.0000

3.0000

4.0000

5.0000

6.0000

Voltage "e" [V]

Caption: This least squares linear regression fit shows the relationship between the output voltage and the pressure differences which induced that output voltage response from the pressure transducer to the DAQ. The slope of 196.63 (N/m 2 ∙V) indicates the calibration factor “C” required to deduce the actual pressure differences in the system from voltage readings.

Part II & Table 3: Modeling Longitudinal Velocity via Bernoulli & Conservation of Mass Analyses

19

20

21

22

23

24

25

12

13

14

15

16

17

18

Trial

No.

1

2

3

8

9

10

11

4

5

6

7

Pass age

Posit ion

(mm)

Data

Stagnat ion

Output

Voltage

(Volts)

Static

Output

Voltage

(Volts)

Stagnatio n

Pressure

(N/m 2 )

Bernoulli

Analysis

Static

Pressure

(N/m 2 )

10 1.2610 -1.3150 246.7495 -259.7810

20 1.2630 -1.3810 247.1428 -272.7588

30 1.2570 -1.3890 245.9630 -274.3319

40 1.2600 -1.3870 246.5529 -273.9387

50 1.2540 -1.3340 245.3731 -263.5170

60 1.2450 -1.2480 243.6034 -246.6065

70 1.2530 -1.1330 245.1764 -223.9935

80 1.2500 -0.9966 244.5865 -197.1725

90 1.2390 -0.8856 242.4235 -175.3461

100 1.2430 -0.7820 243.2101 -154.9748

110 1.2440 -0.6939 243.4067 -137.6513

120 1.2400 -0.5924 242.6202 -117.6929

130 1.2340 -0.5185 241.4404 -103.1616

140 1.2370 -0.4536 242.0303 -90.4000

150 1.2310 -0.3857 240.8505 -77.0485

160 1.2340 -0.3260 241.4404 -65.3094

170 1.2280 -0.2742 240.2606 -55.1238

180 1.2280 -0.2282 240.2606 -46.0786

190 1.2200 -0.1794 238.6875 -36.4828

200 1.2270 -0.1482 240.0639 -30.3478

210 1.2160 -0.0999 237.9010 -20.8445

220 1.2170 -0.0629 238.0976 -13.5670

230 1.2260 -0.0303 239.8673 -7.1548

240 1.2190 -0.0065 238.4909 -2.4922

250 1.2170 -0.0134 238.0976 -3.8336

V = 2(P t

- P s

)/

ρ

(m/s) x (mm) dy

(mm

)

29.0554 76.0000 10

29.4364 66.8571 10

29.4475 62.2857 10

29.4531 57.7143 10

29.1230 53.1429 10

28.5835 48.5714 10

27.9634 44.0000 10

27.1342 44.0000 10

26.3872 44.0000 10

25.7612 44.0000 10

25.2011 44.0000 10

24.5055 45.0105 10

23.9653 46.6947 10

23.5383 48.3789 10

23.0181 50.0632 10

22.6108 51.7474 10

22.1880 53.4316 10

21.8456 55.1158 10

21.4153 56.8000 10

21.2294 58.4842 10

20.7664 60.1684 10

20.4803 61.8526 10

20.2905 63.5368 10

20.0409 65.2211 10

20.0803 66.9053 10

Conservation of Mass

Analysis

Caption: This table shows the recording of output voltage readings from the pressure transducer, both from stagnation pressure and static pressure, over the majority of the longitudinal range in the test section. Conversions between output voltages and pressures were calculated using the least squares linear regression fit curve from Part I. Velocities were obtained using the result for stagnation (also total) pressure from the Bernoulli Equation as equal to the sum of static and dynamic pressure, the latter of which has a velocity term to isolate. The conservation of mass analysis was obtained by recognizing changes in air density were negligible, making it possible to equate inlet volumetric flow rate to flow rate in any cross section along the test section. Since the walls necked in a linear fashion, the simple linear proportion of areas was used to deduce the resulting velocities of that model.

225.05

233.47

241.89

250.32

258.74

267.16

275.58

284.00

292.42

300.84

309.26

317.68

326.11

334.53

A (mm 2 )

380.00

334.29

311.43

288.57

265.71

242.86

220.00

220.00

220.00

220.00

220.00

49.0599

47.2904

45.6441

44.1085

42.6729

41.3278

40.0650

38.8770

37.7574

36.7005

35.7012

34.7548

33.8573

33.0051

V

2

=

(A

1

/A

2

)V

1

(m/s)

29.0554

33.0288

35.4529

38.2611

41.5524

45.4632

50.1866

50.1866

50.1866

50.1866

50.1866

300

Table 4: Pressure vs. Channel Position (Stagnation & Static Pressure Comparison)

Pressure vs. Channel Position

200

100

-200

-300

0

10

-100

60 110 160 210

Channel Position (mm)

Stagnation Pressure Static Pressure

Discussion of Variation of Pressure Difference b/w Total Pressure & Static Pressure:

Trend:

The graph on the left depicts both stagnation (total) pressure in blue and static pressure in red as a function of channel position. Dynamic pressure can be understood as the displacement between the two curves for a given channel position.

It’s important to notice that stagnation (total) pressure stays fairly constant over the whole range while static pressure varies considerably. This is a validation of the result from Bernoulli’s Equation from which we obtained the relation that stagnation

(total) pressure is the sum of static & dynamic pressure. Thus for regions where the flow is approaching a necked region with a small cross sectional area, the flow velocity will increase, increasing the dynamic pressure term and causing the static pressure term to drop in order to compensate.

Trend Conclusions:

Based on this and looking at the figure on the right, we can deduce that the straightwalled midsection which is 70 mm from the inlet and continues to a distance of 114 mm from the inlet, should be the location where the flow velocity is highest and by extension where the static pressure is lowest.

Acknowledgement of Error in Correlating Pstag & Pstatic (Right-shift of bottom curve required):

Thus to approximate, we can assume that half way in this straight-walled midsection, or about 92 mm from the top, should be where the static pressure is lowest. Now this

“well” in our diagram which we would expect to fall between 70-114 mm with a

trough around 92 mm, actually falls in between 10-60 mm with a trough around 40 mm in our graph. What is responsible for this shift to the left? A small procedural error is involved here - although the tube connecting the pitot tube’s stagnation outlet was properly shifted to the static outlet before going down the whole channel and repeating the pressure measurements for static pressure, we failed to align the side holes for static pressure with the scale inside the channel to correlate with the stagnation pressures on the scale. In short, if we were to take a measurement at 50 mm, the stagnation pressure would be taken accurately as the hole in the top of the pitot tube was aligned to 50 mm on the scale. However, the corresponding static pressure we measured and correlated is actually the static pressure of some point in the channel further below 50 mm, because for the static measurements we incorrectly aligned the top of the pitot tube with the scale again. As a result, for the same point in the scale we correlated stagnation pressure values with static pressure values of points further down. Due to the divergence later on in the channel, these correlating static pressures are higher. As a result, the trough we expected in the neck region appears far earlier in our curve.

Visual Adjustment of Data Before Analyzing (Please assume bottom shift to right by 52mm)

How to read our data properly? We simply need to shift all our data points to the right by the distance between the top of the pitot tube and the distance where the side holes for static pressure lie. Unfortunately, we do not have that measurement from the pitot tube so we need to approximate. Since we know our “well” needs to be around 92 mm since that is the middle of the necking region, and the well in our diagram is at 40 mm, the distance between the top of the pitot tube and the side holes is around 52 mm. A shift of 52 mm will make the data correlate correctly and allow for the subsequent analysis to make sense.

Discussion (con’t):

Assuming one can visualize this shift of 52 mm so that the wells line up in the figure as they should, we can now analyze the variation in pressure difference between the total pressure and the static pressure. (we will assume the static pressure well occurs at the middle of the necking region at 92 mm from now on)

While total pressure remains fairly constant, static pressure varies significantly, dropping to a minimum value as the flow approaches and is constricted by the cross section of the neck region, resulting in higher velocities and thus higher dynamic pressures and by extension lower static pressure. The air flow channel then diverges, causing the velocity and dynamic pressure to drop as cross sectional area increases while static pressure increases.

Table 5: Velocity vs. Channel Position From Bernoulli Analysis & From Mass Conservation

Analysis

Velocity vs. Channel Position

40

30

20

60

50

10

0

0

Bernoul l i Ana l ys i s

Vel oci ty

Ma s s Cons erva tion

Vel oci ty

50 100 150 200

Channel Position (mm)

250 300

Caption:

Revisiting Key Right Shift of 52 mm Assumption:

Again the assumption regarding the Bernoulli Analysis which relies on our experimental values of stagnation and static pressure, the later of which needs to be shifted to the right by the distance between the stagnation point on the top of the pivot to the side holes in order to correlate properly – approximated as 52 mm for now – this assumption is still required.

Discussion & Analysis:

With that assumed, the peak of the velocity function with respect to channel position from the (blue) Bernoulli Equation correlates perfectly with the plateau of the

Mass Conservation Curve as both go through the neck region.

In this comparison, only one-dimensional flow is assumed, which means the velocity profile will change with respect to only one direction. This usually refers to parabolic flow which can be derived from Bernoulli’s Equation when shear stress is taken into account, such as the situation in a horizontal pipe assuming no loss.

However, as we can see from mass conservation, where we simply scale the uniform inlet velocity profile by the ratio of cross sectional areas at a given channel position to the inlet area, this can also mean a simple uniform velocity profile as a function of displacement rather than across the channel width as the parabolic 1D velocity profile varies in.

Whichever is the case, we see for both approaches the geometry of the channel, specifically its varying width has a real impact on channel flow as it should since the continuity equation from mass conservation after density is divided out is embedded in the Bernoulli Equation.

Which is more accurate and why?

The only question that remains is why the velocity with respect to channel position is so high when we look at the conservation of mass approach compared to

Bernoulli. Keeping in mind that Ber noulli’s Equation can be used to derive a parabolic laminar flow from shear stress considerations and that the curve from

Bernoulli relied on experimental data describing a flow which most certainly has the kind of boundary layer effects that the wall could have on the velocity profile, whereas the conservation of mass was simply a scaling of the inlet velocity according to geometry, it’s no wonder that the Bernoulli Equation analysis leads to a lower range of velocities and Conservation of Mass analysis has such high velocities because it doesn’t consider such losses.

It is apparent that since the Bernoulli Equation approach takes into account experimental data that is influenced by such boundary layers, it is more representative of the flow and thus is a more accurate method to use.

F. Error Analysis

There were several sources for potential error including improper measurement and calibration and error resulting from defective instrumentation.

While we measured a constant value as our base or ‘zero’ value while calibrating the transducer system, rapid fluctuation may have altered a potentially true zero. These effects can also be considered when assessing accuracy of output voltage measurements after each successive increase in flow through the channel. We can also consider the accuracy of the measurements taken for the manometer water position during each trial. We constantly measured the bottom-most point on the meniscus for consistency, but error could arise from inaccurate manometer readings taken during the experiment, which propagate during calculations for pressures and velocities. Finally, error can exist in the equipment used during the experiment. Voltmeter, Thermometer, Atmospheric Pressure Gages, and Pressure

Transducer Accuracies should always be considered as sources for error. We can also account for even the slightest of leakages in the air flow channel, connections, and the manometer, which would result in variances in pressure and subsequently variances in output voltages.

In calculating the error in our data, we followed the Linear Regression Least-

Squares Curve-Fitting Process to obtain a linear equation y = a + bx by relating pressure variance as a function of output voltage by y = -1.2066 + 196.6345x. The constant value C = b = 196.6345 N/m 2 *Volt is the slope of the equation and relates the dependence of the pressure on voltage, and similarly we can consider the depending of voltage on pressure as the inverse k = 1/C = 0.0051 Volt*N/m 2 Upon further calculation, we find a value for theta of 153.7832 which gives rise to values of uncertain in C and k as u a

=1.4897/u b

=0.5004 and u a

=0.6713/u b

=1.9984 respectively.

These values are relatively small, acceptable errors that can be attributed to any of the sources given above.

G. CONCLUSION

To recap and conclude, this experiment was designed in order to develop a sense of how to calibrate instruments, then use calibration curves from least squares linear regression to convert our voltage signals back to what we assume are accurate representations of what the pressure difference that induced the signal must have been. In our calibration we had the freedom to set what the voltage output would be for some maximum expected pressure difference and assuming a linear scale what this does is allow us to vary the static sensitivity “k” or our calibration constant “C” and essentially how big of a response we get from an instrument in a

change of stimulus. This helps us to better visualize the effects of moving through a range of pressures as the output voltages are more distinct and easier to read.

Calibration also helps us work around the limitations of our instrumentation, such as our Data Acquisition System which may tolerate only so much voltage.

Secondly, we were able to use the pitot tube and air flow bench setup to accurately deduce velocities through the length of a test section from Bernoulli’s result for stagnation pressure. We were able to compare that experimental data with the possible naïve assumption that for air flow where static pressure may not vary significantly in changes of height, thereby assuming that flow can be reduced to conservation of mass or continuity if density is assumed constant. After all, at face value the idea that the gain in velocity is proportional to the area at V2 and the area at the inlet for Vi, makes a lot of sense. However, by verifying Bernoulli’s result, we now see that while we will see some appreciable gain after narrowing the cross section, since Pstag=Pstatic + Pdynamic is a relation that also must be considered, the gain doesn’t scale quite so high.