Chapter 7 Project Management Review Questions What are the uniq

advertisement

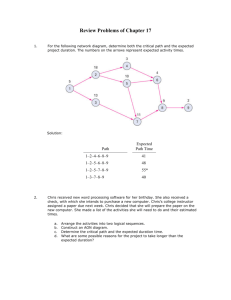

Chapter 7 Project Management Review Questions 1. What are the unique attributes of project management? Frame the answer in terms of other P/OM work configurations. Answer: Projects have life-cycle stages that are unlike those of other work configurations. Specifically, all projects have an endpoint when the goal is achieved. Endpoints can also be viewed as the starting points of the next set of projects. We will get back to that dynamic issue after we examine traditional project characteristics. Projects tend to be unique and aimed at a singular goal, whereas other work configurations tend to do some jobs, products, or tasks repetitively. The scale of projects frequently dwarfs that of other work configurations. For example, the project of building a bridge, or a landing on the moon, is of much longer duration than creating hub caps in a job shop, or assembling cars in a flow shop. Projects tend to require many participants of numerous disciplines using varied resources. The one type of project that now needs to be examined is that of bringing new products to the marketplace. Formerly, that was done in traditional project mode with a planning phase at start-up and ending with a product launch which tracks the growth of the new product’s market share. Within the last two decades, some very successful companies have learned how to keep projects going. As a project ends—another related project begins. It was seen that the development of a product platform for continuous updating and upgrading provided a necessary competitive edge. Ongoing project management keeps the project team always engaged in the project mode. Product platform planning is discussed in Chapter 11 on NPD. 2. Classify projects by type and describe project life cycles. Answer: Projects can be simple or complex; they can be one-time-only, first time ever, or it has-been-done-before. They can be infrequently or frequently done, and they can take days, months or years to accomplish. The four life-cycle stages are (1) describe the goals; (2) plan the project; (3) carry out stages; and (4) complete the project. Step 1 requires establishing the desired outcomes of the project. Step 2 includes full specification of the activities that make up the project (and the interrelationships among activities). Step 2 also includes the determination of an appropriate time line for the project (and its critical path). The third step is the operational aspects of the project. Build the walls, pour the floors after the pipes and wires have been installed, etc. The last step—for traditional projects—includes shutdown and team dissolution. However, as previously mentioned, increasingly, the team moves on to another project which is likely to be the next phase of the prior project. 1 3. Why is a project manager considered a leader? Answer: The project manager in many ways must possess characteristics of a chief executive. This certainly qualifies as a leadership position. Such a manager is in charge of a project that has a return only at its conclusion; there may be no revenue stream or profits. Project managers are guided by strategic management, yet need to work toward cycle-time reduction in all facets of the project. Project managers must be systems-oriented because projects combine human skills, technological capabilities, and resources from many parts of multiple organizations. Projects pose considerable risks, and presage great penalties for failure. For all of these reasons, projects need leaders, not just managers. Leadership is the ability to get others (the entire project team) to follow in exactly the right way. The leader must not only know how to get people to follow; the leader must know “the right way.” 4. What is team work and why is team work repeatedly mentioned when discussing good project management? Answer: Projects are large-scale and unique. They utilize large amounts of organizational resources from many areas of the organization. To be successful—such large events require the systems philosophy to promote coordination and, hence teamwork. Projects are of long duration; the workers assigned to a project may stay with it for its lifetime while it evolves over many stages and phases. Such a semi-permanent combination of workers fulfilling on a changing set of demands is a team. Projects are so wide-ranging—involving all parts of the organization and some extra-organizational elements of the supply chain. Scope is huge and challenging. The systems philosophy is strategic and team work is its tactical response. Good project management may include concurrent engineering (CE). This subject is not treated in Chapter 7 but parallel-path project activities are discussed. Wikipedia has a good explanation of concurrent engineering. For our purposes, we will briefly point out that CE is inherently a team-oriented method. Concurrent means that several related initiatives are proceeding together in parallel. Parallel path project management demands coordinated team efforts to achieve synergy which translates into reduced time for completion with superior results. (The definition of synergy is: “things working together produce an effect greater than the sum of their individual effects.) For example, two drugs were tested and each had some small benefits but when used together, their effectiveness jumped. Parallel-path project management can have the same effect. 5. What is PERT’s relationship to critical-path methods? Answer: PERT and CPM (critical path method) were developed at the same time (parallel needs) but entirely independently. As separate developments in the 1950s PERT and CPM were commissioned and paid for by different organizations (see section 7.5). PERT uses 3 parameters to estimate activity times and this approach is considered to be better for projects with stochastic event durations. CPM stressed quick determination of the longest time path 2 in the project, called the critical path (CP). CPM was considered to be better for problems involving “crashing”—spending extra funds to complete selected activities sooner. It is fair to say that over time differences between PERT and CPM have all but disappeared. Each has incorporated the uniquely strong points of the other. Both emphasize the value of finding the critical path and then being able to adjust it by allocating resources in different ways. 6. What does the forward-pass procedure accomplish in critical-path methods? Answer: The forward pass is the fastest way to score a touchdown in the NFL. However, since we are talking about project management, the forward pass identifies the earliest start time of each of the activities in the network. Knowing the durations of the activities, the earliest finish times are readily calculated. The earliest finish of the last or final activity determines the target date and time for completion of the project (e.g., of the entire network). This target date and time determines the length of the critical path. It sets the stage for the backward pass calculations. Project managers do not call this a lateral pass. 7. What does the backward-pass procedure accomplish in critical-path methods? Answer: The backward pass calculates the latest finish times for each of the activities in a project network. By subtracting the durations of the activities, latest start times are calculated. This is done working backwards from the final activity to the first activity. As a result of the backward pass, the critical path can be identified. With the forward-pass, only the length of the critical path was known. After the backward-pass, slack values are known. The critical path is identified as the set of activities with zero slack. 8. What is a critical path and how does knowing it in detail help project managers? Answer: The critical path is the set of activities that constitutes the longest time path through the network. Delay at any one of the activities on the critical path will delay the entire project. Activities on the critical path have zero slack—as measured by latest start minus earliest start equals zero. The subtraction of latest finish minus earliest finish will also equal zero. The managerial importance is in knowing which tasks cannot be delayed without delaying the entire project. The opposite is also important to the manager, namely, which tasks can be delayed without disturbing the project’s due date. Such information is vital to decisions about moving resources from one task to another. This is done to speed up slow tasks that benefit by being faster at the expense of fast tasks that are unnecessarily so. 9. What is slack and how does knowing exactly what it is and where it resides help project managers? Answer: Activities along the critical path have zero slack. Activities that are not on the critical path have positive slack. Think of slack as allowable slippage which is the time that an activity can be delayed without impacting the completion time of the project. Knowing 3 which activities have very little slack allows management to expedite those activities lest they become part of the critical path. It is worth considering putting more resources to work on critical slack activities. Knowing which activities have a lot of slack permits management to consider swapping resources from large slack activities to minimum slack activities. In short, it encourages project managers to study if resource swapping can bring better balance to project activities. The process of moving resources from where they are excessive to where they are limiting is known as resource leveling. 10. What are the differences between deterministic and probabilistic activity time estimates? Answer: If an activity time is deterministic, then its duration is a constant. Deterministic means that there is no variation in that activity time. When activity time is stochastic its duration is a variable dependent upon a probability distribution. Variation complicates calculation of critical paths and renders uncertain the length of the critical path as well as the amount of slack that characterizes each activity. If variation exists in activity times, it is very likely to be foolhardy to take the averages and act as if they are deterministic activity times. 11. What are the strengths and weaknesses of PERT? Answer: PERT uses the concept of a critical path—with time estimates adjusted for the stochastic nature of activity durations. This three parameter adjustment is a significant strength, when compared to project methods that cannot handle variation in activity times. PERT offers a reasonable approach for calculating likelihoods of project duration based on the distributions related to the three parameters. It is critical that that both the Expected time and the Activity variance be used together to determine the probability that a non-critical activity can become critical. The major weakness of PERT is that the three parameter method (which is based on the Beta distribution) does not capture the realities of actual activity variations. Another weakness is that project managers may use only Expected time and ignore the Activity variance measure. When probabilities affect which activities will be part of the actual critical path, it is crucial to plan for both eventualities—even though one may have a much greater probability than the other. 12. Describe how cost/time trade-off methods can be used given the decision to spend an additional 10% on the project. Answer: Cost/Time analysis is the basis for “crashing” activities and projects. In one of its simple forms, it assumes a linear relationship between extra spending on an activity and the time reduction that results. If an additional 10% is available, and that money is not sufficient for a complete crash, managers must choose which critical tasks are shortened and which are not. Cost/Time trade-off analysis shows where the greatest leverage exists. Less simple is the non-linear variant of these trade-off functions. These can show expenditures that achieve large reductions in activity times at first, which then gradually slow up—as more is spent on resources. The reverse is also possible. Non-linear trade-offs are more complex to calculate. 4 The computers are not the scarce resource; programmers are. It seems reasonable to guess that the increased accuracy of non-linear trade-off analysis may be well worth the effort. 13. Describe project crashing and contrast it to normal time. Answer: Crashing is based on assigning extra resources to complete a project in minimum time. “Crash” time for an activity is its minimum duration, as shortened by added resources. “Normal” time reflects activities with minimum resource needs. Normal time is associated with reasonable expenditures. Less than that amount would jeopardize the success of the project. Smart crashing would have managers use resources where they have the greatest leverage. Crashing only has leverage with critical (or near-critical) tasks. By calculating the deltas (change in cost per change in duration) some activities will be preferred to others for crashing. Managers should start with critical activities having the lowest delta. 14. What advantages can be gained by using crashing? Answer: The value of crashing is a reduced critical path time. The advantage of a shorter critical path may be more profit or bonus for the project organization, more prestige for the early completion, or the avoidance of a penalty for late completion. Most important is the ability of an early start-up to start generating revenue before Since activities are “crashed” by adding more resources, managers must be concerned with where these extra resources can be obtained (let’s talk to finance). A manager acting without the systems viewpoint could spend more on crashing than is being saved by the early completion. Also, a manager may crash the wrong activities (a noncritical activity, or an activity that has become noncritical. Another systems point is that crashing can shift the critical path. Further, the linearity assumption relating spending on resources to time reduction may not be valid. In this case, the extra resources may not have the desired impact. A study to determine the nonlinear shape of cost reduction with increased expenditure adds to the cost of crashing. 15. What are the dangers of, using crashing? Answer: The value of crashing is a reduced critical path time. The advantage of a shorter critical path may be more profit or bonus for the organization, more prestige for the early completion, or the avoidance of a penalty for late completion. When Boeing delivers a 787 airplane ahead of time a complex sequence of advantages occurs including cash flow to Boeing, passenger revenues generated by flights flown, on-board and maintenance crew salaries, etc. Since activities are “crashed” by adding more resources, managers must be concerned with what these extra resources cost. A manager acting without the systems viewpoint could spend more on crashing than is being saved by the early completion. Also, a manager may crash the wrong activities (a noncritical activity, or an activity that has become noncritical. Another systems point is that crashing can shift the critical path. Further, the linearity assumption relating spending on resources to time reduction may not be valid. In 5 this case, the extra resources may not have the desired impact. A study to determine the nonlinear shape of cost reduction with increased expenditure adds to the cost of crashing. 6 Problems 1. Consider the following AON network and the data given in the following table to answer the next four questions. Activity Time (days) A 5 B C 6 7 D E F G 4 9 3 4 B E D A G C a. Identify the critical path. Answer: A-B-D-E-G b. Find the earliest completion time of the project. Answer: 28. This is the length of the critical path. c. Find ES, EF, LS, and LF of each activity Answer: See the table below. d. Find the slack for each activity. Answer: See the table below. Solution List all paths and identify the longest path. A-B-D-E-G: 28 days (longest path, critical path, gives the project duration) A-B-D-F-G: 22 days A-C-F-G: 19 days 7 F Table showing calculations for ES, EF, LS, LF and Slack Time Activity Time ES EF LS LF A 5 0 5 0 5 Slack Time 0 B C D E F 6 7 4 9 3 5 5 11 15 15 11 12 15 24 18 5 14 11 15 21 11 21 15 24 24 0 9 0 0 6 G 4 24 28 24 28 0 8 2. The Delta Company manufactures a full line of cosmetics. A competitor recently developed a new skin rejuvenating cream that appears to be successful and potentially damaging to Delta’s skin care position in the marketplace. The sales manager has asked the operations manager what the shortest possible time would be for Delta to reach the marketplace with a new product packaged in a competitively redesigned container. The operations manager has drawn up the following table. Activity Description Design product Design package Test market package Distribute to dealers Order package materials Fabricate package Order materials for product Test-market product Fabricate product Package product Activity Symbol A B C D E F G H I J Immediate Follower H and G E and C D None I and F D I and F J J D Duration (Days) 30 15 20 20 15 30 3 25 20 4 a. Construct the AON diagram. Answer: See the diagram below. b. Find the critical path Answer: A-G-F-D. This is the longest path (83 days). See the list of paths below. c. Find the ES, LS, EF, and LF. Answer: See the table below. d. What is the project duration? Answer: 83 days. This is the length of the critical path. All paths are listed below. e. Determine the slack of each activity. See the table below. f.Neither the sales manager nor the P/OM is satisfied with the way the project is designed. However, the P/OM insists that because of the pressure of time, the company will be forced to follow this plan. In what ways does this plan violate good practice? The project has several serious flaws. Materials for both the product and the package are ordered while they are still being individually test-marketed. The notion of separate test markets for the product and the package runs counter to good systems practice. They should be tested together. Further, fabrication of the product and package is scheduled to begin before either of the test markets has been completed. This will not allow ideas for improvement gained during test marketing to be incorporated into the product and package. A further discrepancy arises from the fact that the product is to be packaged 9 before the activity “fabricate package” is completed. This difficulty should be cleared up before the project schedule is approved. Finally, there is too little slack along a number of paths. That makes the length of the critical path a risky bet which can be dependent upon relatively minor events in activities A, G, F, and D. Also, activities B and E in adjacent paths are able to shift the critical path from AGFD to BEFD. This kind of uncertainty creates a project management nightmare. Solution AON Diagram H J A G I D E F B C There are following six paths in this network. The numbers in parentheses are the lengths of the paths. A-H-J-D (79) A-G-I-J-D (77) A-G-F-D (83) B-E-I-J-D (74) B-E-F-D (80) B-C-D (55) 10 Table showing calculations for ES, EF, LS, LF and Slack Time Activity Description Design product Design package Test market package Distribute to dealers Order package materials Fabricate package Order materials for product Test-market product Fabricate product Package product Activity Symbol A Immediate Follower H and G Duration (Days) 30 ES EF LS LF 0 30 0 30 Slack Time 0 B E and C 15 0 15 3 18 3 C D 20 15 35 43 63 28 D None 20 63 83 63 83 0 E I and F 15 15 30 18 33 3 F D 30 33 63 33 63 0 G I and F 3 30 33 30 33 0 H J 25 30 55 34 59 4 I J 20 33 53 39 59 6 J D 4 55 59 59 63 4 11 3. Consider the data given in the following table. The fixed cost is $ 900 per week. Perform a time-cost tradeoff analysis. What is the minimum cost to complete the project and what is the corresponding time? Immediate Activity Predecessor (s) Normal time (Weeks) Crash Time (Weeks) Normal Cost Crash Cost A None 9 6 $13,000 $15,550 B C D E F G H I J None None A B B C D,E F,G,H I 5 7 12 8 6 11 5 4 10 4 5 8 5 4 9 4 3 8 $7,000 $15,000 $12,000 $9,000 $5,000 $13,000 $8,000 $2,500 $12,000 $7,900 $15,800 $14,800 $10,500 $6,200 $14,000 $9,000 $3,500 $15,000 Answer Minimum Cost: $132,050 Time: 33 Days Solution The solution of this problem requires crashing of activities and then finding the total cost. The total cost includes the activity cost and the fixed cost. Various tables showing these calculations are given below. Also see the Excel file SMCh07. 12 Table showing calculations of cost of crashing per week and maximum crashing possible Activity Crashing Data Activity Immediate Predecessor (s) A B C D E F G H I J NONE NONE NONE A B B C D,E F,G,H I Normal Time (Weeks) Crash Time (Weeks) 9 5 7 12 8 6 11 5 4 10 Total Cost 6 4 5 8 5 4 9 4 3 8 Activity on Node (AON) Diagram 13 Normal Cost ($) Crash Cost ($) $13,000 $7,000 $15,000 $12,000 $9,000 $5,000 $13,000 $8,000 $2,500 $12,000 $96,500 $15,550 $7,900 $15,800 $14,800 $10,500 $6,200 $14,000 $9,000 $3,500 $15,000 $112,250 Cost of Crashing per Week ($) Maximum Crashing Possible (Weeks) $850 $900 $400 $700 $500 $600 $500 $1,000 $1,000 $1,500 3 1 2 4 3 2 2 1 1 2 Crashing Process Paths Schedule 1 Schedule 2 Crash D by 4 Weeks Schedule 3 Crash A by3 Weeks Schedule 4 Crash H by 1 Week Schedule 5 Crash I by 1 Week 0 4 3 1 1 2 40 32 25 32 36 32 25 32 33 32 25 32 32 31 24 32 31 30 23 31 29 28 21 29 0 700 850 1000 1000 1000 Increase in activity cost because of crashing 0 2800 2550 1000 1000 2000 Total Activity Cost 97000 99800 102350 103350 104350 106350 Normal Schedule Number of weeks crashed A-D-H-I-J B-E-H-I-J B-F-I-J C-G-I-J Cost of Crashing/week for activities that are chosen for crashing Schedule 6* Crash J by 2 Weeks The critical path consists of activities A-D-H-I-J with a schedule time of 40 weeks. Activities are crashed on the critical path in ascending order of their costs of crashing per week. Path A-D-H-I-J continues to be the critical path until Schedule 3 after D is crashed by 4 weeks and A is crashed by 3 weeks. The project length is now 33 weeks. In Schedule 4, one of the three activities, H, I and J can be picked up for crashing. Each one of them has $ 1,000 cost of crashing per week. Activity H is picked up for crashing by one week using alpha order. After H is crashed, two paths, A-D-H-I-J and C-G-I-J become critical. The project length is now 32 weeks. Activity I and J are then crashed by one and two weeks respectively leading to Schedule 6. At this stage all activities on path A-D-H-I-J have been crashed. Project duration can not be reduced any more. Fixed Cost per week Time vs. Cost Analysis 900 Project Time Crashing Cost Activity Cost 29 1000 106850 30 1000 105350 31 1000 104350 32 1000 103350 33 850 102350 34 850 101500 35 850 100650 36 700 99800 37 700 99100 38 700 98400 39 700 97700 40 0 97000 Fixed Cost 26100 27000 27900 28800 29700 30600 31500 32400 33300 34200 35100 36000 Minimum Total Cost Project Duration Total Cost 132950 132350 132250 132150 132050 132100 132150 132200 132400 132600 132800 133000 132050 33 14 4. Consider the data given in the following table and answer the questions that follow. Activity Immediate Predecessor (s) Normal Time (days) Crash Time (days) Normal Cost $ Crash Cost $ A B C D E None A A B and C D 4 4 1 3 2 2 3 1 2 1 200 300 200 600 500 400 600 200 650 900 a. What is the normal project time? Answer: 13 days b.Identify the critical path? Answer: A-B-D-E c. What is the normal cost of the project? Answer: $ 1,800. This is the total of the normal costs of all activities. d.If the project time is to be reduced by one day, which activity should be crashed first? What is the cost of crashing per day of activity E? Answer: The critical path is A-B-D-E. The cost of crashing activity D is the smallest. Therefore, crash D. The cost of crashing activity E is $ 400 per day. See the table below. Solution: The AON diagram is given below. B D A E C There are 2 paths that are listed below. The numbers in parentheses show the length of the two paths. A-B-D-E (13) A-C-D-E (10) A-B-D-E is the longer path – the critical path. This gives a project duration of 13 days. 15 Table showing calculations for the cost of crashing per day. Activity A B C D E Immediate Predecessor (s) None A A B and C D Normal Time (days) 4 4 1 3 2 Crash Time (days) 2 3 1 2 1 Normal Cost $ Crash Cost $ 200 300 200 600 500 400 600 200 650 900 Cost of Crashing per Day 100 300 n.a. 50 400 Maximum Crashing Possible 2 1 0 1 1 5. There are two paths in a network (see below). The length of Path 1 is 30 days and that of Path 2 is 28 days. You are now told that activity F which currently takes 4 days will actually take 3 days more, that is, 7 days. What will be the project duration with this revised time? Path 1: A-B-D-E-G Path 2: A-C-D-F-G Answer: 31 days. Solution The current project duration is 30 days (length of path 1). The length of path2 will become 31 days (28 + 3) if activity F takes 3 days more. The length of path 1 remains unchanged. Therefore, the project duration becomes 31 days. 6. There are two paths in a network (see below). The length of Path 1 is 30 days and that of Path 2 is 28 days. You are now told that activity D which currently takes 2 days will actually take 3 days more, that is, 5 days. What will be the project duration with this revised time? Path 1: A-B-D-E-G Path 2: A-C-D-F-G Answer: 33 days. Solution The length of path 1 will become 33 days and the length of path 2 will become 31 days if activity D takes 3 more days. 16 7. Suppose the length of critical path in a project is 40 days. There are four activities A, B, C and D on the critical path. The variances of these activities are: A (1.4), B (1.2), C (0.9) and D (0.4). What is the probability of completing the project within 42 days? Answer: 0.0844 Solution Variance of the critical path = 1.4 + 1.2 + 0.9 + 0.4 = 3.9 Standard Deviation of the critical path (σ) = 1.9748. Due Date (D) = 42 days Length of critical path (T) = 40 days. z = (D-T)/ σ = (42-40)/1.9748 = 1.01274. The probability corresponding to a z value of 1.01274 is 0.8440. See the z-table for finding the probability. 8. Suppose the length of critical path in a project is 50 days and the standard deviation is 2 days. What due date should be set for the project so that the probability of completing the project is 90%? Round the answer to the nearest higher integer. Answer: 52.57 Solution Length of critical path = 50 days Standard deviation (σ) = 2 The z-value for a probability of 0.9 is 1.285. The due date is calculated from the formula z = (D-T)/ σ. D = z * σ + T = 1.285*2 + 50 = 2.57 + 50 = 52.57. 9. Suppose the length of critical path in a project is 35 days. The probability of completing the project within 34 days is: (a) Less than 50% (b) Greater than 50% (c) Equal to 50% (d) Cannot be determined from the above data Answer: (a) Less than 50%. Solution: The due date is smaller than the length of the critical path. Therefore, the probability of completing the project by the due date is less than 50%. It may be noted that if the due date is equal to the length of the critical path then the probability of completing the project by the due date will be 50%. In the formula, z = (D-T)/ σ, the value of z will be 0 (zero) since D =T. For z = 0, the probability is 50%. The value of σ is immaterial. 17 18