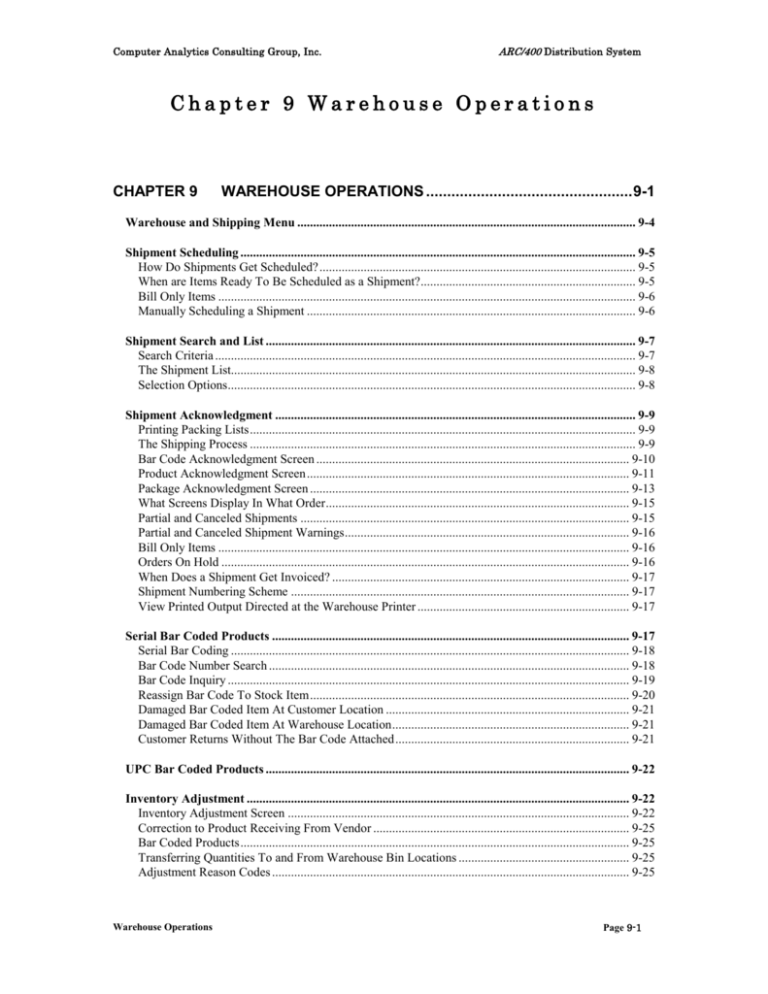

Chapter 9 Warehouse Operations

advertisement