MT226 - Mohawk Valley Community College

advertisement

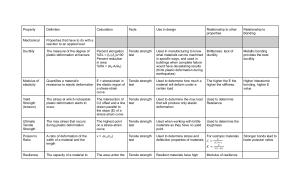

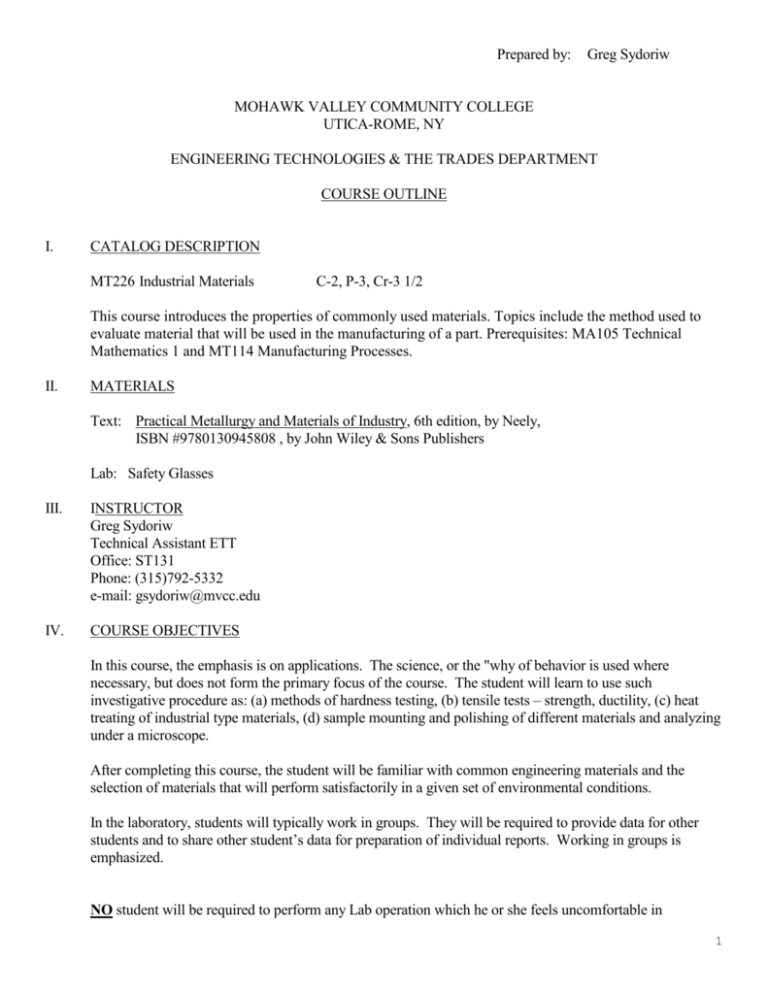

Prepared by: Greg Sydoriw MOHAWK VALLEY COMMUNITY COLLEGE UTICA-ROME, NY ENGINEERING TECHNOLOGIES & THE TRADES DEPARTMENT COURSE OUTLINE I. CATALOG DESCRIPTION MT226 Industrial Materials C-2, P-3, Cr-3 1/2 This course introduces the properties of commonly used materials. Topics include the method used to evaluate material that will be used in the manufacturing of a part. Prerequisites: MA105 Technical Mathematics 1 and MT114 Manufacturing Processes. II. MATERIALS Text: Practical Metallurgy and Materials of Industry, 6th edition, by Neely, ISBN #9780130945808 , by John Wiley & Sons Publishers Lab: Safety Glasses III. INSTRUCTOR Greg Sydoriw Technical Assistant ETT Office: ST131 Phone: (315)792-5332 e-mail: gsydoriw@mvcc.edu IV. COURSE OBJECTIVES In this course, the emphasis is on applications. The science, or the "why of behavior is used where necessary, but does not form the primary focus of the course. The student will learn to use such investigative procedure as: (a) methods of hardness testing, (b) tensile tests – strength, ductility, (c) heat treating of industrial type materials, (d) sample mounting and polishing of different materials and analyzing under a microscope. After completing this course, the student will be familiar with common engineering materials and the selection of materials that will perform satisfactorily in a given set of environmental conditions. In the laboratory, students will typically work in groups. They will be required to provide data for other students and to share other student’s data for preparation of individual reports. Working in groups is emphasized. NO student will be required to perform any Lab operation which he or she feels uncomfortable in 1 performing. STUDENT LEARNING OUTCOMES 1. Students will use investigative procedures like methods of hardness testing. 2. Students will use investigative procedures like tensile lists-strength, ductility. 3. Students will be able to identify metal deformation, the making and shaping of metals, and alloys of metal steel and iron. 4. Students will be able to identify strengthening mechanisms, fracture, fatigue, ductility transmission temperature, age hardening, creep and corrosion 5. Students will be able to identify with common engineering materials and the selection of materials that will perform satisfactorily in a given set of environmental conditions. 6. Students will be able to show how structure is related to properties through microscopic examinations. 7. Students will have to provide data for other students. 8. Students will have to share other student’s data for preparation of individual reports. 9. Students will show how to work in groups effectively. 10. Students will be exposed to red hot metals when working in the lab. 11. Students will be working in dangerous situations so safety is the primary consideration in all lab operations. 12. Students will not be required to perform lab operations if he/she feels uncomfortable. V. COURSE OUTLINE Chapters covered with lectures and take home tests: 1 22 3 7 10 5 6 14 15 20 21 2 4 (bonus) Lab/Reports to include but not limited to: - Hardness testing with Rockwell testers - Heat Treating of Industrial Materials and then testing with Rockwell Hardness Tester - Mounting of Industrial Samples with Buehler Mounting Presses - Polishing of Industrial Samples on sanding/polishing tables - Analyze samples under the microscope 2 VI. GRADING 50% 25% 25% 10% 110% Chapter Take Home Tests Lab Reports and Participation Attendance Attitude 3 COURSE NAME:____MT226 INDUSTRIAL MATERIALS________________________________________________________ DATE FACULTY NAME CHANGE INPUT MEASUREMENT ASSESSMENT ACTION 1