1. Introduction

advertisement

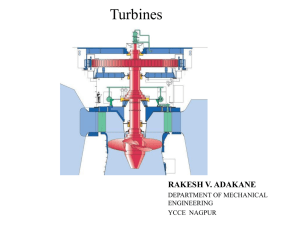

A Experimental Analysis on Francis Turbine & to find out the power and efficiency on diferent types of heads. Neeraj Kumar1, Gourav Dureja2 M.M.Group of Institutions,Ramba Karnal,India Neeraj_4296@yahool.com1 2 gurugourav@gmail.com2 M.M.Group of Institutions,Ramba Karnal,India gurugourav@gmail.com ABSTRACT The objective of this article is to analyse the power & efficiency of Francis turbine and analyze its performance with different heads.This article will help the researchers while working on francis turbine & analyzing its various components. In this article we study the details of francis turbine & measure the power output on francis turbine.This article will provide background and progress of various parameters in Educational field.. The future directions of the commercial activities to implement the new findings will be the central theme. The immerging new partnership and challenges projected will also be discussed. This article will help engineering schlor in their experiments while analising . Keywords: francis turbine , head ,manometer,energy,pressure, discharge 1. INTRODUCTION Francis turbine named after james bichens francis , is a rection type of turbinie for medium high to medium low heads & medium small to medium large quantity of water. Francis Turbine is a prime over. It converts the hydraulic energy (head of water) into mechanical energy, which in turn can be transformed into electrical energy by coupling a generator to the turbine. Francis Turbine is a radial inward flow reaction turbine. This has the advantage of centrifugal force acting against the flow, thus reducing the tendency of the wheel to race. Generating energy from the power of water represents large amounts of clean, renewable energy. 71 percent of the earth’s surface is covered by water. The world’s hydro power potential amounts to 20 billion Mega Watt hours per year and only 30 percent of this has been developed so far 2. Various Parts of Francis Turbine The main parts of Francis Turbine are: 2.1 CASING The runner is completely enclosed in an air-tight spiral casing. The casing and runner are always full of water.casing is used for safety purposes & splashing of water from outside. 2.2 GUIDE MECHANISM It consists of a circular wheel all round the runner of the turbine. The stationary guide vanes are fixed on the guide wheel. The guide vanes allow the water to strike the vanes fixed on the runner without shock at inlet. Also width between the two adjacent vanes can be altered so that amount of water striking the runner can be varied. Fig 1. Guide Vanes 2.3 RUNNER It is a circular wheel on which a series of Radial Curved Vanes are fixed. The vanes are so shaped that the water enters and leaves the runner with out shock. Fig 2. Runner 2.4 DRAFT TUBE The pressure at the exit of the runner of Reaction Turbine is generally less than atmospheric pressure. The water at exit cannot be directly discharged to the tail race. A tube or pipe of gradually increasing area is used for discharging water from the exit of turbine to the tail race. This tube of increasing area is called Draft Tube. One end of the tube is connected to the outlet of runner while the other end is sub-merged below the level of water in the tail-race. Fig 3. Components of Francis Turbine 3 Working of Francis Turbine 3.1 Reaction Turbines Reaction turbines are those turbines which operate under hydraulic pressure energy and part of kinetic energy. In this case, the water reacts with the vanes as it moves through the vanes and transfers its pressure energy to the vanes so that the vanes move in turn rotating the runner on which they are mounted. The main types of reaction turbines are 3.1.1. Radially outward flow reaction turbine: This reaction turbine consist a cylindrical disc mounted on a shaft and provided with vanes around the perimeter. At inlet the water flows into the wheel at the centre and then glides through radially provided fixed guide vanes and then flows over the moving vanes. The function of the guide vanes is to direct or guide the water into the moving vanes in the correct direction and also regulate the amount of water striking the vanes. The water as it flows along the moving vanes will exert a thrust and hence a torque on the wheel thereby rotating the wheel. The water leaves the moving vanes at the outer edge. The wheel is enclosed by a water-tight casing. The water is then taken to draft tube. 3.1.2. Radially inward flow reaction turbine: The constitutional details of this turbine are similar to the outward flow turbine but for the fact that the guide vanes surround the moving vanes. This is preferred to the outward flow turbine as this turbine does not develop racing. The centrifugal force on the inward moving body of water decreases the relative velocity and thus the speed of the turbine can be controlled easily. 3.1.3 Runner with vanes: The runner is mounted on a shaft and the blades are fixed on the runner at equal distances. The vanes are so shaped that the water reacting with the m will pass through them thereby passing their pressure energy to make it rotate the runner. 4 Diagram of Francis Turbine 4.1 Francis turbine : The principal feature of a francis turbine that distinguishes it from an impulse turbine is that only a part of the total head available at the inlet to the turbine is converted to velocity head, before the runner is reached. Also in the reaction turbines the working fluid, instead of engaging only one or two blades, completely fills the passages in the runner. The pressure or static head of the fluid changes gradually as it passes through the runner along with the change in its kinetic energy based on absolute velocity due to the impulse action between the fluid and the runner. Therefore the cross-sectional area of flow through the passages of the fluid. A reaction turbine is usually well suited for low heads. A radial flow hydraulic turbine of reaction type was first developed by an American Engineer, James B. Francis (1815-92) and is named after him as the Francis turbine. The schematic diagram of a Francis turbine is shown in Fig. 4 Figure.4 Francis turbine 4.2 A Francis turbine comprises mainly the four components: 4.2.1 spiral casing, 4.2.2 Guide on stay vanes, 4.2.3 Draft-tube as shown in Figure 3 4.2.4 Runner blades, 4.2.1 Spiral Casing : Most of these machines have vertical shafts although some smaller machines of this type have horizontal shaft. The fluid enters from the penstock (pipeline leading to the turbine from the reservoir at high altitude) to a spiral casing which completely surrounds the runner. This casing is known as scroll casing or volute. The crosssectional area of this casing decreases uniformly along the circumference to keep the fluid velocity constant in magnitude along its path towards the guide vane. Figure 28.2 Spiral Casing This is so because the rate of flow along the fluid path in the volute decreases due to continuous entry of the fluid to the runner through the openings of the guide vanes or stay vanes. 4.2.2 Guide or Stay vane: The basic purpose of the guide vanes or stay vanes is to convert a part of pressure energy of the fluid at its entrance to the kinetic energy and then to direct the fluid on to the runner blades at the angle appropriate to the design. Moreover, the guide vanes are pivoted and can be turned by a suitable governing mechanism to regulate the flow while the load changes. The guide vanes are also known as wicket gates. The guide vanes impart a tangential velocity and hence an angular momentum to the water before its entry to the runner. The flow in the runner of a Francis turbine is not purely radial but a combination of radial and tangential. The flow is inward, i.e. from the periphery towards the centre. The height of the runner depends upon the specific speed. The height increases with the increase in the specific speed. The main direction of flow change as water passes through the runner and is finally turned into the axial direction while entering the draft tube. 4.2.3 Draft tube: The draft tube is a conduit which connects the runner exit to the tail race where the water is being finally discharged from the turbine. The primary function of the draft tube is to reduce the velocity of the discharged water to minimize the loss of kinetic energy at the outlet. This permits the turbine to be set above the tail water without any appreciable drop of available head. A clear understanding of the function of the draft tube in any reaction turbine, in fact, is very important for the purpose of its design. The purpose of providing a draft tube will be better understood if we carefully study the net available head across a reaction turbine. 5 OBSERVATIONS / CALCULATION / RESULT* Data:- g = 9.81m/s2 Pm =1360kg/m3 D dR W3 Pw Cv =0.08m = 0.012m dB =1.2 Kg W4 =1000 kg/m3 =0.98 =0.2m =0. Kg Ps,M m Hg h1 cm h2 cm W1 Kg W2 Kg n 3650 Pd Kg/ cm2 20 7.5 12 15 0 0 0% 2 3320 20 6 12 16 1 34% 3 2930 19.5 5.5 10.5 16 2 4 2630 19 5 10.2 16.2 3 5 2300 18.5 4.5 10.5 16.5 4 6 2130 18.5 3 16.5 16.5 5 0.15 0 0.30 0 0.50 0 0.75 0 1 S.No. N, RPM 1 32% 25% 21% 19% Table 1 5 CALCULATIONS: H= 10(Pd + Ps/ 760), m of water =…15.26 m of water A= π/4 D2 , m2 =…5.02x10-3. m2 V = CV X√ 2GH X (ρm/ ρw -1) , m/sec =2.67m/sec T= (W 1+W3-W2) X g X Re , Nm =0.955 Nm Eo = 2x π x N x T/60x1000 , KW = 0.332 KW Q= Vx A, m3/Sec=0.013 m3/Sec h=h1- h2/100 m =0.03m Ei = ρw x gx Q x H/100 ,KW = 9.60KW Re = dB + 2dR/2 ,m =0.112 m ηt = Eo/ Ei x 100 % = 34 % 7 NOMENCLATURE :A = Cross – Sectional area of pipe , m2 D= Diameter of Pipe , m dR= Diameter of rope ,m Eo= Output Power , kW g=Acceleration due to gravity , m/s2 h=Differential Pressure of manometer , m N=RPM of runner shaft Ps=Suction pressure , mmHg Re = Equivalent Radius ,m V=Velocity of water , m/s W2=Dead weight (obtain from spring balance ),Kg W4= Weight of rope , Kg pm=Density of Manometer fluid i.e.Hg,kg/ m3 Cv= Coefficient of pilot tu db= Diameter of brake drum , m Ei=Input power kW H=Total head , m h1, h2=Manometric reading at both pints , CM Pd=Devilry Pressure ,kg/cm2 Q=Discharge m3 /sec T=Torgue/Nm W1= Applied weight ,Kg W3=Weinght of hanger , Kg pw=Density of water ,kg/ m3 nt=Turbine efficiency References [1] Collaboration for Establishing Francis Turbine Manufacturing and Testing Facility in Nepal, Supriya Koirala*, Sudip Adhikari, Biraj S. Thapa, Bhola Thapa, and Ole G. Dahlhaug, Rentech Symposium Compendium, Volume 1, March 2012 [2] Voith Hydro Holding GmbH & Co. KG ,Alexanderstrasse 11 ,89522 Heidenheim/Germany ,Tel. +49 7321 37 0 Fax +49 7321 37 7828 ,info.voithhydro@voith.com ,www.voithhydro.com, A Voith and Siemens Company [3] A Text Book of Fluid Mechanics and Hydraulic Machines. Front Cover. R. K. Bansal. Firewall Media, Jan 1, 2005 Fluid mechanics [4] Hydraulics and Hydraulic Machines ,. M.N. Shesha Prakash, Professor, J.N.N. College of Engineering, Shimoga , [5] Modeling of fluid flow inside UMP’S francis turbine using ,computational fluid dynamics (CFD) , Muhammad nur bin hashim , Faculty of Mechanical Engineering University malaysia pahang , Thesis , ( November ,2009) [6] Mr. Sudip Adhikari is a graduate of Mechanical Engineering from Kathmandu University (KU), and is working at the Turbine Testing Lab as a Research Assistant. AUTHOR: Neeraj Kumar received the B.Tech in Mechanical Engineering from N.C.C.E (ISRANA) panipat, haryana During 2008 & M.Tech in thermal Engineering From NIT KKR INDIA DURING 2012.he join the MMGI ramba karnal India college as a assistant professor in mechanical department. Gourav Dureja received the B.Tech in Civil Engineering from M.M.University Mullana Haryana During 2013 he join the MMGI ramba karnal India college as a Lecturer in Civil Department.