Marshall Muffler Case - SAP Instructional Materials Site

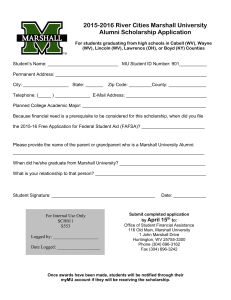

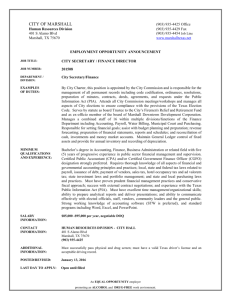

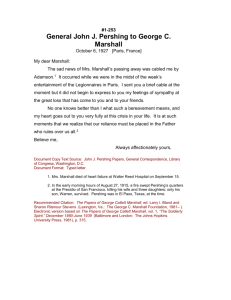

advertisement

Marshall Muffler Case A-M consulting has just completed a very successful SAP implementation for the Fitter Snacker company. A-M is a partnership formed by Beth Aven and Cristin McCurly, who both had extensive experience in SAP implementation as key leads with Kobbler foods, and Fitter Snacker was the first implementation for A-M. They have just reached an agreement with the Marshall Muffler company to manager their SAP implementation. Although neither Aven or McCurly have automotive experience, the are convinced that the secret to a successful ERP system implementation is to have a good plan, focus on business processes and understand change management. In fact, they feel that their lack of automotive experience can be a benefit: it will allow them to ask all the “dumb” questions that frequently lead to process improvements. A-M has taken advantage of their Fitter Snacker implementation experience by documenting, in great detail, all of the steps and data they used for Fitter Snacker. They have organized these steps into 13 modules. Fitter Snacker and Marshall Muffler are different companies in different businesses, and as a result, the data contained in the modules documenting the Fitter Snacker configuration will not be the same for Marshall Muffler. Nevertheless, the modules provide a great template for any implementation project. A-M is growing and needs additional implementation consultants. That is why they have hired you. You have completed the first step in your training process—configuring an example of the Fitter Snacker company using the documented modules. The next step in your training is to configure another company—Marshall Marshall— using the Fitter Snacker documentation modules as a guide and data provided from a preliminary site visit by A-M management to Marshall Muffler. In addition, you will configure Marshall Muffler in the Fitter Snacker training client. This means that you will be able to do much of this training configuration by copying and modifying Fitter Snacker data. Copying and modifying is always easier than trying to create something from scratch. The primary goal of your configuration project is to produce an SAP system that can manage the purchase of raw materials and production and sale of mufflers. As a result, you are allowed to cut some corners. For example, you can use the same general ledger accounts for Marshall Muffler as you did for Fitter Snacker. In the real implementation, detailed analysis and study is needed to design an appropropriate general ledger structure. In addition to the Fitter Snacker documentation modules and Marshall Muffler data, there is a PowerPoint presentation that highlights important issues in using the Fitter Snacker documentation for Marshall Muffler. Finally, there is the following FAQ information which should help guide your efforts. FAQ (Frequently Asked Questions) regarding the Marshall Muffler Configuration Training Q: Can you describe Marshall Muffler’s Business? Marshall Muffler Manufacturing produces three similar models of automotive mufflers— Model 8286, Model 8289 and Model 8290. These mufflers are assembled from components that Marshall Muffler purchases from outside suppliers (louver tubes and shells), as well as components that they manufacture themselves from raw materials they purchase (steel pipes and rolls of sheet steel). Inlet Bushing Muffler Shell Louver Tubes Outlet Head Inlet Head Outlet Bushing Partitions Front View Side View Q: Can you describe how a muffler works? Marshall Muffler produces cylindrical mufflers. Mufflers are basically a set of tuned chambers through which car/truck exhaust passes that will minimize the pulsating sound produced by the engine. The cylinder is formed by a steel shell which is separated into chambers by partitions: Partitions Head Shell Shell Partitions Head Head Chambers 2 The chambers act like air springs. In addition to chambers, pulses are dampened by having the exhaust gasses flow through louver tubes—perforated steel tubes. Having the exhaust gasses flow through these tubes also helps to smooth out exhaust gas pulses. The pipes that connect the muffler to the rest of the exhaust system are called bushings. Not only do the partitions create air chambers, they support the louver tubes and bushings. The heads are end caps that are similar to partitions. The primary difference is that their outer edges are roll-formed onto the shell, much like the lid of a tin can.. Q: Can you describe the manufacturing process Marshall Muffler uses? Marshall Muffler buys a few of the parts used in manufacturing its mufflers. It buys the outer shell because it does not have the equipment to form metal of that size. It also buys louver tubes because Pontiac Pipe Products has a proprietary process that can make them much cheaper than Marshall can. Marshall forms its own bushings because the production equipment is relatively inexpensive and flexible, which allows them to make these parts on what is almost an “as needed” basis. It makes these bushings from pipe purchased from Pontiac Pipe. Pontiac Pipe produces pipe in high volumes for a number of customers and so it can take advantage of high volume production equipment. Marshall Muffler uses a standard size pipe and has had reliable delivery from Pontiac with a 3 day lead time. The bushing manufacturing process involves two steps performed at two different workcenters. First, the pipe purchased from Pontiac Pipe is cut to length at a cutoff workcenter. These cut lengths of pipe are then taken to the bushing workcenter, where the Swage machined necks end of pipe down Riesener machines makes sure end of pipe is round Swage Operation 3 Marshall stamps partitions and head from rolls of steel in two operations. First, the roll of steel is uncoiled and stamped into round discs called blanks. Stamping Machine These blanks are then processed in a dial press, which rotates the blank through a series of dies to form the disc into either a partition or a head. Partitions and heads are very similar. For both parts, the dial press stamps holes to support louver tubes and/or bushings and also forms the rim. For partitions, the rim is a right/angle bend that creates a larger surface area to seal to the shell. For the head, the rim is formed so that it can be rolled over the edge of the shell in the assembly operation to produce an air-tight seal. Blanks Steel Roll Dial Press Form rim Stamp holes Form radius Dial press forming operations Dial Press die set 4 The muffler components are assembled at the muffler assembly line. This multi-station line has a number of operations that press fit louver tubes into the partitions. These partition-louver tube sub-assemblies are in turn press fit into the shell. The inlet bushing is press fit into the inlet head while the outlet bushing is press fit into the outlet head. In the last operation, the heads are pressed against the shell sub-assembly and the rim is rolled onto the shell to complete the muffler assembly. Shell Louver Tube Partition Head Bushing Muffler Assembly Shell s Partition-louver tube subassemblies Muffler Assembly Line 5 Q: How important are the numbering schemes? These number schemes: Numbering for organizational structures, e.g. company code, purchasing organization Numbering for materials are very important. Following these schemes will make life much easier for you and your fellow consultants-in-training. In addition, some grading may be done automatically, and you may not get credit if you have not used the correct number. Q: What if I accidentally use an incorrect number? Fix it. You can leave unused data in the system and it won’t hurt anything. But you would want to archive (remove with an auditable record) any bad data in the real production system. Q: I’m confused on how to tell SAP what material number to use. How do you do it? You can specify the material number to use in the initial screen to create a material by entering the number in the Material field. Remember that when SAP says material, it means the material number, which must be unique. People tend to think of the Description, which is just a text field that describes the data. Enter material number here When the user specifies the material number, that is called an externally assigned material number. If you leave the material (number) field blank, then SAP will assign the number (internally assigned). Remember that you have to specify the material number in the initial screen—you can’t change it when you are entering data in material master views: 6 Nothing was entered in the material master field, so SAP assigned (internally) a material number. It cannot be changed at this point—you have to cancel and start over. Q: I’m confused about creating, changing and views when it comes to materials. Can you clarify this? Sure. The first time you create a material, you are creating both the material and at least one view. You either enter a (unique) material number, or let SAP do it. See the answer above. Once you have created a material, the material now exists, with whichever views you created on this “first” creation. It is very common in practice for data for a material to be “created” over time, that is, for different views to be added by different parts of an organization as a product is developed. For example, the basic data views might be created first by product development or engineering. Next, the accounting and costing views might be added. Purchasing may then add their views once they begin to determine a supply source. Production planning may add their views even later. Every time a view is added to an existing material, it is done under the Create Material transaction (MM01), even though the material (with some views) exists. A common mistake is to accidentally create a new material rather than adding views to an existing material. This happens when the material number of the existing material is not entered in the initial screen: 7 Suppose you wish to add the MRP1 and MRP2 views to material ##M286. If you enter the material number in the initial screen for the Create Material transaction, the SAP R/3 system will find this (existing) material and create the new views for it. The SAP R/3 system will confirm that it found the material and is adding views to it by displaying the following message at the bottom of the screen: If the Material field is left blank, SAP will create a new material with an internally assigned number If you forget to enter ##M286 for the material, you will be creating a new material with only the MRP1 and MRP2 views. You will not receive the message that the material exists and will be extended. A clue to your error will be that you will not have a description for the material—because the SAP R/3 system will not have pulled that information up from the database. The following figure illustrates the problem of creating a new material rather than extending an existing one: Basic Purch. MRP1 MRP2 ACTY Cost Create Material Basic Purch. Acty Cost Material ##M286 Material ##M286 Basic Purch. Acty Cost Material ##M286 Create Material MRP 1 Material ##M286 (unchanged) Material MRP 2 Material 17 8 Q: I’m confused about which materials should be raw, which should be semifinished and which should be finished. How do I figure this out? Raw materials (ROH) are materials that we purchase but do not sell—we use them to produce our own products. There are seven raw materials for the Marshall Muffler company—steel rolls, pipe, shells and the four louver tubes. Finished materials (FERT) are materials that we manufacture and sell. The three mufflers are our finished products. The remaining materials are semi-finished (HALB). We don’t buy them, and we don’t sell them. They are intermediate materials in our production process. All of the remaining materials—bushings, partitions and heads—are semi-finished materials. In the Fitter Snacker modules, we create the raw and finished materials in Module 5 and then add the MRP and work scheduling views in Module 10. We create all views for the semi-finished materials in Module 11. You can create the semifinished materials along with raw and finished following Module 5 instructions, or you can wait until Module 10. Q: What if I create a material as the wrong material type? Surprisingly enough, you can change the material type rather easily. Follow the menu path: Logistics Production Master Data Material Master Material Change Material Type The SAP system will ask you to confirm the valuation class (used to determine which G/L account records the value of this material in inventory): Select 3000 if the material type is being changed to raw, 7900 if the material type is being changed to semi-finished, and 7920 if the material type is being changed to finished. 9 Q: What if I forget to enter the weight in the material master for the mufflers. Everything will be fine until you try to save a sales order for the mufflers. Without a weight for the mufflers, the sales order will be incomplete and you will not be able to process it further until you provide a weight for the sales order. Q: What units of measure should I use? For Marshall Muffler, everything material is a discrete (countable) quantity, so either Each (EA) or Piece (PC) can be used. For the sheet steel rolls, EA or PC is fine, but ROLL (RL) may be more descriptive. Q: What are the alternative units of measure for the mufflers? Alternative units of measure allow us to display a material in different units of measure— case quantities, pallet quantities, truckload quantities, etc. There is no requirement for alternative units of measure for Marshall Muffler, so you don’t have to configure this for the project. Q: What lot sizes should I use for the materials? The lot-for-lot (EX) lot size is best. It will only require you to produce exactly what is needed to meet demand, which will minimize the chance that you will run out of raw materials and have to place more purchase orders. Q: I’m not clear about creating vendors and the instructions. What is this Create central thing again? Data for vendors (suppliers) exists in two areas—MM (materials management) and FI (financial). We need MM data to manage the purchasing process, and FI data to pay them. In the real world, vendor data might be created in the MM module first, then the FI data might be created next. Or, as we did in the Fitter Snacker exercise, we can create the FI data first (Module 4.1), then add the MM data (Module 4.2). For the Marshall Muffler exercise, we can both sets of data at the same time. SAP calls this creating the vendor centrally. Module 4.3 shows you how to do this. Q: I’m trying to create a purchase order and the assign vendor function isn’t working. I don’t get the pop-up window that lets me choose the vendor. What’s wrong? Nothing. With the Fitter Snacker exercise, we had multiple vendors for each material. In that case, the SAP system had to ask us which vendor to use. In the case of Marshall Muffler, there is only one vendor for each material. When we ask the SAP system to 10 assign the vendor, there is only one option, so the SAP system makes the assignment without asking us for more data. It tells us has successfully made the assignment by turning off the highlighting of the material. Q: I’m trying to pay the vendor invoice and I get the message “You may only post documents up to USD 10,000.00. How can I make this payment? You need to increase the limits for the default tolerance group. Refer back to Module 6.4. Q: I’m really not looking forward to entering all that account determination information again. Is there any way around that? Yes, there is. The SAP programmers were pretty smart when they designed Automatic account determination. Remember that automatic account determination is the process SAP uses to figure out which general ledger accounts are affected by materials management and production transactions. It’s what allows the accounting to be done automatically whenever we use, move or produce materials without having to enter that accounting transaction separately. We just tell SAP what we did to the material, and it does all the accounting automatically. The SAP programmers had us define the automatic account determination for a valuation grouping code rather than a plant or company code. Because we are using Fitter Snacker GL accounts for Marshall Muffler, we can easily using use the automatic account determination we defined for Fitter Snacker. In Module 8.1, simply assign your Marshall Muffler company code to your Fitter Snacker valuation grouping code. Then you can skip steps 8.2 through 8.6. Q: I don’t understand how to set up the bills of material (BOMs). What is used to make what? Each muffler is assembled from the following components: 1 shell 1 inlet bushing 1 outlet bushing 3 louver tubes 3 partitions 1 inlet head 1 outlet head Each muffler is unique in terms of the actual bushings, heads, partitions and louver tubes used, but the construction is similar. 11 For the bushings, heads and partitions, the BOM actually represents a disassembly process. The BOM for bushings needs to show that 20 bushings are produced from one pieces of pipe. This is done by specifying 20 in the header quantity, and one in the item quantity: 20 bushings are produced from one piece of pipe 12 Similarly, heads and partitions are stamped (disassembled) from a roll of steel. One roll of steel will produce 500 heads or 500 partitions. Note that mistakes in the BOM for bushings, heads and partitions will create problems when MRP runs are calculated. These problems are not easy to correct. Q: What should I use for the workcenter capacity? Assume each workcenter operates 24 hours per day, and that the number of elements that make up the capacity for each group (No. of indiv. cap.) is one for all workcenters Q: I don’t understand the routings. How do they work for the bushings, heads and partitions. For Fitter Snacker, the production process was pretty simple. Everything was done at one workcenter. For Marshall Muffler, some of the parts—specifically the bushings, heads and partitions—need to be processed at two workcenters. This is easily accomplished by listing each workcenter, in order, on the routing. For example, the bushing routing should look like this: 13 Q: What control keys do I use for the Marshall Muffler routings? The following control keys have been created in the system for the Marshall Muffler exercise: Muffler assembly: Pipe cut-off: Bushing: Stamping: Dial press: MFLR PIPE BSHG STMP PRSS) Q: Do I have to configure all of the controlling module for the Marshall Muffler exercise.? No. In practice the controlling module is critical as it provides managers with the cost accounting information to understand how to make the company more profitable. For this exercise, we only need to configure enough of the CO module so that we can process production orders. Specifically, we only need to do 9.1 to 9.3, 9.6 and 9.10 in Module 9. Q: There is a lot of data to be entered. Is there any way to simplify the data entry task? Yes. Most data entry transactions allow the user to copy from existing date. This will allow you to copy most of the settings/data automatically and will dramatically speed up the time it takes to complete the project. In addition, it will reduce the number of data entry errors. The copy from option is useful for G/L accounts, Material Masters, BOMs and Routings. 14 For G/L Accounts For the Marshall Muffler training exercise, we will use the same GL Accounts as we did for Fitter Snacker. This allows us to create the GL accounts very simply. You use the same create GL accounts transaction, but use the “Create w/Template” icon: Use the search to find each GL account, click on create w/Templae In the pop-up window, enter the same GL account number with the FS company code Using the Create w/Template option, all of the Fitter Snacker GL account settings will be copied. Then all you have to do is save the new GL account. For Material Masters Once you have created one material (louver tube, for example) you can create similar materials more easily using the “Copy from….” option. In the “Create Material” screen, first specify the material to copy from: 15 after specifying the views to create, you will get the following pop-up window for specifying the organizational levels: Specify the organizational level to create and to copy from (should be the same for Marshall Muffler) Click on the enter icon, and all of the data will be copied from the existing material. Make sure you change values that are different, like moving price. For BOMs Similar to materials, once you have create a BOM for a material, you can copy it to create the BOM for a similar material. 16 Enter the data for the new BOM, then click on Copy From icon Enter the information for the BOM, then click on the Copy From icon: Specify the information for the BOM you wish to copy For Routings You can use the Copy From option in a similar fashion to the BOMs. 17 Click on the Copy from icon After clicking on the Copy from icon, you will get a pop-up window: Select Routing, then you can specify the routing to copy from: 18 Specify the routing to copy Q: Do I have to do the Sales and Operations Planning process? No. You can create planned independent requirements (which are what drive the MRP process) by following the menu path: Logistics Production Production Planning Demand Management Planned Independent Requirements Create Enter the material number, plant and version 00: 19 Enter the material number for a muffler, your plant and version 00, then click enter Enter the quantity you want to produce a few months into the future Click on the save icon. Q: I can’t do a goods issue for my muffler production order. It says the material does not exist. What is wrong? 20 There are two reasons this might happen. One, you are trying to build mufflers before you build all the components needed to manufacture them (bushings, partitions and heads). Another reason may be that you haven’t specified the correct storage location. You can check where your materials are stored from the Stock/Requirements List. Click on the magnifying glass on the stock row: Click on the Stock Overview button on the bottom of the popup window: and you will be able to see where your material is stored: All of the material is in storage location 100 in this case 21