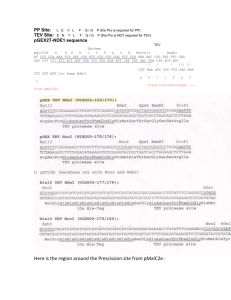

appendices - The TEV Project

advertisement