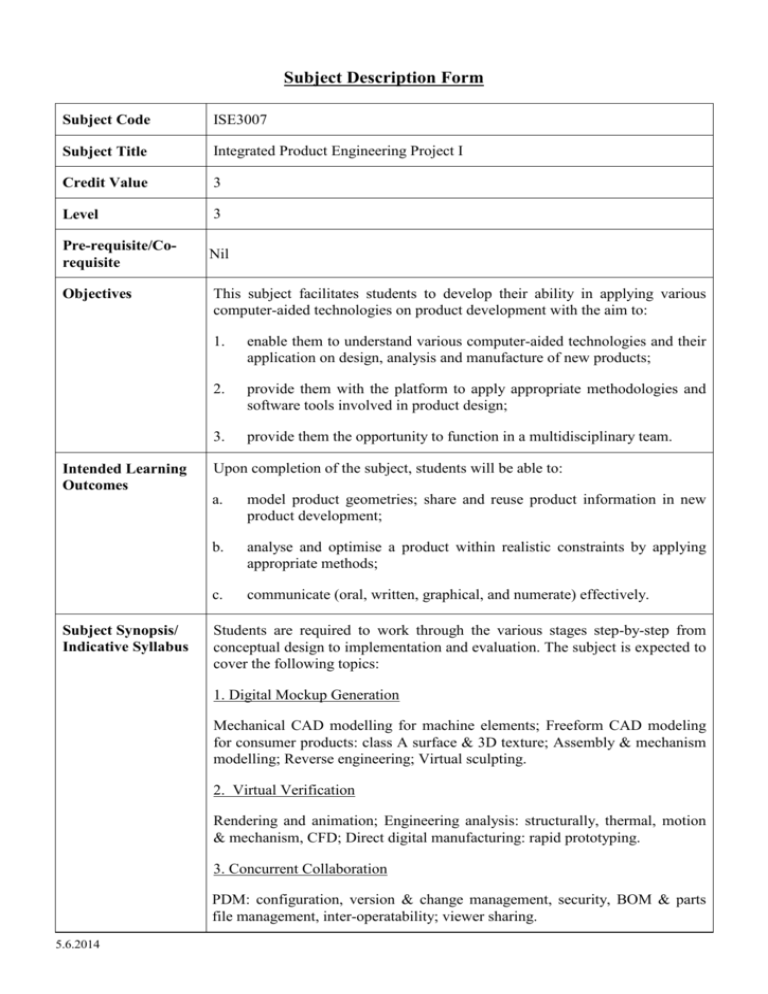

ISE3007: Integrated Product Engineering Project I

advertisement

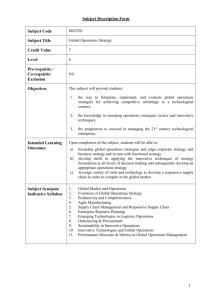

Subject Description Form Subject Code ISE3007 Subject Title Integrated Product Engineering Project I Credit Value 3 Level 3 Pre-requisite/Corequisite Nil Objectives Intended Learning Outcomes Subject Synopsis/ Indicative Syllabus This subject facilitates students to develop their ability in applying various computer-aided technologies on product development with the aim to: 1. enable them to understand various computer-aided technologies and their application on design, analysis and manufacture of new products; 2. provide them with the platform to apply appropriate methodologies and software tools involved in product design; 3. provide them the opportunity to function in a multidisciplinary team. Upon completion of the subject, students will be able to: a. model product geometries; share and reuse product information in new product development; b. analyse and optimise a product within realistic constraints by applying appropriate methods; c. communicate (oral, written, graphical, and numerate) effectively. Students are required to work through the various stages step-by-step from conceptual design to implementation and evaluation. The subject is expected to cover the following topics: 1. Digital Mockup Generation Mechanical CAD modelling for machine elements; Freeform CAD modeling for consumer products: class A surface & 3D texture; Assembly & mechanism modelling; Reverse engineering; Virtual sculpting. 2. Virtual Verification Rendering and animation; Engineering analysis: structurally, thermal, motion & mechanism, CFD; Direct digital manufacturing: rapid prototyping. 3. Concurrent Collaboration PDM: configuration, version & change management, security, BOM & parts file management, inter-operatability; viewer sharing. 5.6.2014 Teaching/Learning Methodology This is an activity-orientated subject which adopts a project-based learning approach. Although no formal lectures are given, briefings/seminars and laboratory/tutorial sessions are available to provide students guidelines and assistance in conducting the project. Students are divided into groups of about five members and work on a product-based project. The teaching and learning activities in each stage of the project are used to facilitate students to achieve the intended learning outcomes by reflection, imitation, and experience. Feedback will be given to students for making improvement. Assessment Methods in Alignment with Intended Learning Outcomes Specific assessment methods/tasks % weighting Intended subject learning outcomes to be assessed a b c 1. Progress Assignments 70% 2. Final Report 30% Total 100% In each of the assessment components above, it consists of both “group work” and “individual work” to reflect the students’ performance. The progress of the project is assessed periodically to monitor the students’ achievement towards the intended learning outcomes (a), (b), and (c) via seven progress assignments. Final oral presentation and report allows students to demonstrate their abilities in presenting their projects clearly and logically including the project objectives, their approaches to solve the problem and the deliverable of their projects. It is appropriated for the assessment of all intended learning outcomes. Student Study Effort Required Class contact: Briefings/seminars and tutorial/laboratory sessions Other student study effort: Preparation of reports and oral presentation Guided Study/Self-learning Reading List and References 5.6.2014 39 Hrs. 42 Hrs. 45 Hrs. Total student study effort 1. Akin, John Edward 2010, Finite Element Analysis Concepts: via SolidWorks, World Scientific 2. Burden, Rodger 2003, PDM: Product Data Management, Resource Pub 3. Chua, Chee Kai, Leong, K. F., & Lim, C. S. 2010, Rapid Prototyping: Principles and Applications, World Scientific 3/e 4. Lee, Kunwoo 1999, Principles of CAD/CAM/CAE Systems, Addison- 126 Hrs. Wesley 5.6.2014 5. Otto, K. 2001, Product Design: Techniques in Reverse Engineering and New Product Development, Prentice Hall 6. Vaughan, William 2012, Digital Modeling, New Riders 7. Training materials published by the Industrial Centre, The Hong Kong Polytechnic University