UF Policies - Biology Major

advertisement

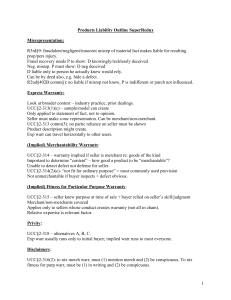

PRINCIPLES OF THE BIOSCIENCE INDUSTRY COURSE NUMBER: TBD TWO CREDIT HOURS SEMESTER/YEAR: TBD UF CAMPUS, UF CERHB BIOTILITY (ALACHUA) CLASS MEETING TIME(S): CLASS WILL MEET ONE DAY/WEEK (PERIODS 9-11, 4:05-7:05) INSTRUCTOR: Dr. Richard Snyder ARB RG-291, rsnyder@cerhb.ufl.edu, 386-418-1642 OFFICE HOURS: Wednesday & Friday, by appointment COURSE TA OR COORDINATOR: Tammy Mandell (tmandell@cerhb.ufl.edu), Lori Wojciechowski (lwojo@ufl.edu), UF CERHB Biotility 386-418-8199 **COURSE WEBSITE: TBD ** COURSE COMMUNICATIONS: email, phone REQUIRED TEXT: Yali Friedman, Building Biotechnology: Business, Regulations, Patents, Law, Policy, Politics, Science, Logos Press; 4th Edition (2014) ISBN-13: 978-1934899298. In addition, students will be required to purchase a course pack, which includes lecture materials, industry documentation to be used in class, and laboratory activities. MATERIALS AND SUPPLIES FEE: $40 ADDITIONAL RESOURCES: FDA Website- http://www.fda.gov Lab coats, non-latex gloves and safety glasses are available in class. COURSE DESCRIPTION: An introduction to the practices, skills and careers in the biotechnology industry providing an applied understanding of regulatory compliance, product development, process development, manufacture, testing, and release-for-sale of biomedical products. Through lecture and hands-on laboratory applications, students learn the profiles of major departments, and participate in simulated departmental roles. PREREQUISITE KNOWLEDGE AND SKILLS: Biology and Chemistry: BSC 2011, BSC 2011L, CHM 2046 and CHM 2046L. PURPOSE OF COURSE: Created in response to industry demand for employees with pre-existing knowledge and experience working in a regulated (cGMP compliant) environment, this course provides students the opportunity to learn and apply critical elements associated with the development, production, testing, and commercialization of biomedical products in the marketplace. In addition, this course will assist students make the transition from performing academic research, to applying science concepts and skills to careers in the biotechnology industry, including pharmaceutical, biopharmaceutical, diagnostic, or medical device. COURSE GOALS: Upon completion of this course you will have an understanding of the methods and strategies involved in biomedical product discovery, development, manufacturing, and testing processes, including the quality systems required for regulatory compliance. You will gain practical experience in applying current Good Manufacturing Practices to the manufacture and testing of biomedical products by participating in production, quality control, and quality assurance activities. AND/OR OBJECTIVES: By the end of this course, students will: 1. Describe the major steps from discovery of a biomedical product to commercialization for human use. 2. Understand regulations, regulatory compliance and current Good Manufacturing Practices and how they are applied to key areas of a regulated industry. 3. Describe the major industry departments, associated careers, and their primary role in ensuring the release of a regulatory compliant product. 4. Explain general strategies used in biomanufacturing to ensure that vaccines, antibodies and biopharmaceuticals are pure, efficacious, and safe. 5. Understand the principles that underlie operations used in upstream (fermentation, cell culture) and downstream processing of biopharmaceuticals (e.g., homogenization, centrifugation, filtration, chromatography, and ultrafiltration). 6. Describe the chemical and physical properties of biomacromolecules and how those properties influence the design of assays. 7. Name critical parameters monitored during upstream and downstream bioprocessing and how they demonstrate process control. 8. Write and execute standard operation procedures (SOPs), batch records and test records for biomanufacturing and testing. 9. Analyze common bioprocessing failures to determine root cause and recommend corrective actions; 10. Describe the stages and purpose of both process validation and assay validation 11. Explain the major drivers of Biotechnology business development TEACHING PHILOSOPHY: Through active participation in this course, you will quickly practice concepts and skills that will expand your understanding of the drug discovery – to – product continuum, and that will assist in your preparation for a variety of bioscience-related careers. INSTRUCTIONAL METHODS: Topics are presented in blended lecture/hands-on format, making efficient use of laboratory time by delivering relevant lecture topics during biomanufacturing and quality testing laboratory exercises. The course includes a variety of learning activities, including: small group discussions, individual written assignments, and participation in simulated industry jobs. A collection of learning media (classroom lecture, company simulations, internet-based, case studies) will be utilized. Reading assignments will include documents from regulatory agencies, and published case studies to explore quality compliance issues related to regulations published by the United States Food and Drug Administration (FDA) and other international Regulatory Agencies. COURSE POLICIES: ATTENDANCE POLICY: Because this course is designed to simulate workplace experiences in the biotechnology industry, attendance and active participation are mandatory. Students will drop one full grade for each unexcused absence. Up to 2 absences are allowed for a passing grade. Requirements for class attendance and make-up exams, assignments, and other work in this course are consistent with university policies that can be found at: https://catalog.ufl.edu/ugrad/current/regulations/info/attendance.aspx. **QUIZ/EXAM POLICY: A mid-term and a cumulative final exam are scheduled. See section on class policies and procedure regarding questions about exam scores and requests for makeup exams. MAKE-UP POLICY: students are allowed to make up exams that are missed due to religious holidays, and for unavoidable, excused absences. **ASSIGNMENT POLICY: Weekly activities, an audit exercise, a midterm, and a final exam assess the student’s knowledge of the subject matter. **COURSE TECHNOLOGY: Instrumentation used in class will include cleanroom simulator, a shaking incubator for cell growth, biosafety cabinet, spectrophotometer, pH meter, high speed and high capacity centrifuges, electrophoresis equipment, gel imaging system, micro and macro pipetting systems, and basic lab ware. All equipment will be available only during designated class periods. COURSE EVALUATIONS: Students are expected to provide feedback on the quality of instruction in this course by completing online evaluations at https://evaluations.ufl.edu. Evaluations are typically open during the last two or three weeks of the semester, but students will be given specific times when they are open. Summary results of these assessments are available to students at https://evaluations.ufl.edu/results/ UF POLICIES: UNIVERSITY POLICY ON ACCOMMODATING STUDENTS WITH DISABILITIES: Students requesting accommodation for disabilities must first register with the Dean of Students Office (http://www.dso.ufl.edu/drc/). The Dean of Students Office will provide documentation to the student who must then provide this documentation to the instructor when requesting accommodation. You must submit this documentation prior to submitting assignments or taking the quizzes or exams. Accommodations are not retroactive, therefore, students should contact the office as soon as possible in the term for which they are seeking accommodations. UNIVERSITY POLICY ON ACADEMIC MISCONDUCT: Academic honesty and integrity are fundamental values of the University community. Students should be sure that they understand the UF Student Honor Code at http://www.dso.ufl.edu/students.php. **NETIQUETTE: COMMUNICATION COURTESY: All members of the class are expected to follow rules of common courtesy in all email messages, threaded discussions and chats. [Describe what is expected and what will occur as a result of improper behavior] http://teach.ufl.edu/docs/NetiquetteGuideforOnlineCourses.pdf GETTING HELP: For issues with technical difficulties for E-learning in Sakai, please contact the UF Help Desk at: ● Learning-support@ufl.edu ● (352) 392-HELP - select option 2 ● https://lss.at.ufl.edu/help.shtml ** Any requests for make-ups due to technical issues MUST be accompanied by the ticket number received from LSS when the problem was reported to them. The ticket number will document the time and date of the problem. You MUST e-mail your instructor within 24 hours of the technical difficulty if you wish to request a make-up. Other resources are available at http://www.distance.ufl.edu/getting-help for: Counseling and Wellness resources Disability resources Resources for handling student concerns and complaints Library Help Desk support Should you have any complaints with your experience in this course please visit http://www.distance.ufl.edu/student-complaints to submit a complaint. GRADING POLICIES: 35% - Participation & Attendance: Students will drop one full grade for each unexcused absence. Up to 2 absences are allowed for a passing grade. Participation includes: o Active discussion on assigned readings 15%. o Completion of laboratory activities associated with biomanufacturing and testing 10%. o Completion of documentation associated with biomanufacturing and testing activities 10%. 15% - Written Essay (5 pages [not including cited references], double-spaced, topic choice will be approved), and 5 min. Report 25% Mid-Term 25% - Final Exam (25 Multiple Choice for 75 pts., one Essay Question for 25 pts.) GRADING SCALE: Passing Grade A Grade Points 4.0 A3.67 B+ 3.33 B 3.0 B2.67 C+ 2.33 C 2.0 C1.67 D+ 1.33 D 1.0 D0.67 E 0 S/U 0 For more detailed information about grades and grading policies please see: http://www.isis.ufl.edu/minusgrades.html http://gradschool.ufl.edu/catalog/current-catalog/catalog-general-regulations.html#grades COURSE SCHEDULE: Assigned Reading Discussion Held each class period in addition to scheduled activity Week 1 Date 8/27 Lecture/Lab Topic Reading Drug Development Overview P. 3-12 Development of Biotech Regulations, Regulatory compliance, Current Good Manufacturing Practices P. 19-27 Molecular Biology Assignment/Activity Lab Safety Procedures Equipment Overview P. 29-40 Drug Development Industry Documentation 2 9-3 Departmental Roles & Organization P. 119-150 Regulations P. 327-331 Career Development Company Model: Making cGMP compliant Popcorn Departmental Role Handouts 3 9/10 Product (Plasmid) Overview Raw Materials Document Training P. 209-226 Research & Development Student “companies” formed (Manufacturing & QA/QC) QA Issue of Docs to QC and Manuf. Innoculate media to start batch 4 5 9/17 9/24 In-Process Monitoring & Control Manuf.- Read Production Batch Record (PBR) Manuf: Harvest cells per Batch Record Product Purification Methods QC - Read Test Record (TR) for A600 QC: Test Record for A600 (Cell growth) Final Formulation & Fill Finish P. 89-118 Patents & IP Manuf: Lyse Cells, Purification Assay Validation QC TR for pH P. 161-182 Company Formation Manuf. PBR 6 10/1 Choose FDA paper topic P. 151-160 Policy QC: Testing of Final Product P. 183-207 Finance QA: Document review (product release) Manuf. PBR 7 10/8 Testing for Endotoxin QC: Test Record for pH of Raw Material QC TR for A260/280, TR for Endotoxin, TR for Gel Electrophoresis (purity and identity) Manuf: FDA Warning Letters Mid Term Mid Term Read Test Record for balance calibration Calibration of balance using NIST weights Navigating FDA Website 8 10/15 Deviations, Planned Variance, and Corrective & Preventative Action Switch roles Calibration & Preventive Maintenance Document Training, QA Issue of Docs to QC and Manuf. Innoc. media to start batch 9 10/22 Project Management P. 227-250 Marketing Manuf. Read Production Batch Record (PBR) 10 10/29 Manuf: Harvest cells per Batch Record QC Read Test Record (TR) A600 QC: Test Record for A600 (Cell growth) Building Systems & Facility Design P. 251-270 Licensing, Alliances, & Mergers Manuf: Lyse Cells, Product Purification Equipment Qualification and Validation Manuf. PBR QC TR for pH QC: Test Record for pH of Raw Material P. 271-286 Managing Biotech QC: Testing of Final Product Manuf. PBR QA: Document review (product release) Product Changeover 12 11/5 Presentations of 5000 level (Investigation of a product recall) QC TR for A260/280, TR for Endotoxin, TR for Gel Electrophoresis (purity and identity) Manuf: FDA Warning Letters 13 11/12 Medical Devices Product Labeling & Shipping 14 11/19 15 12/3 16 12/17 P. 287-300 International Biotech FDA Paper Due 5 min. Presentations Cleanrooms & Gowning 5 min. Presentations Cont. Environmental Monitoring Gown, enter cleanroom, perform particle count, and aseptic product vialing. Review Tour of RTI-Surgical and Sid Martin Biotech. Incubator Final Exam