Radiographic Testing

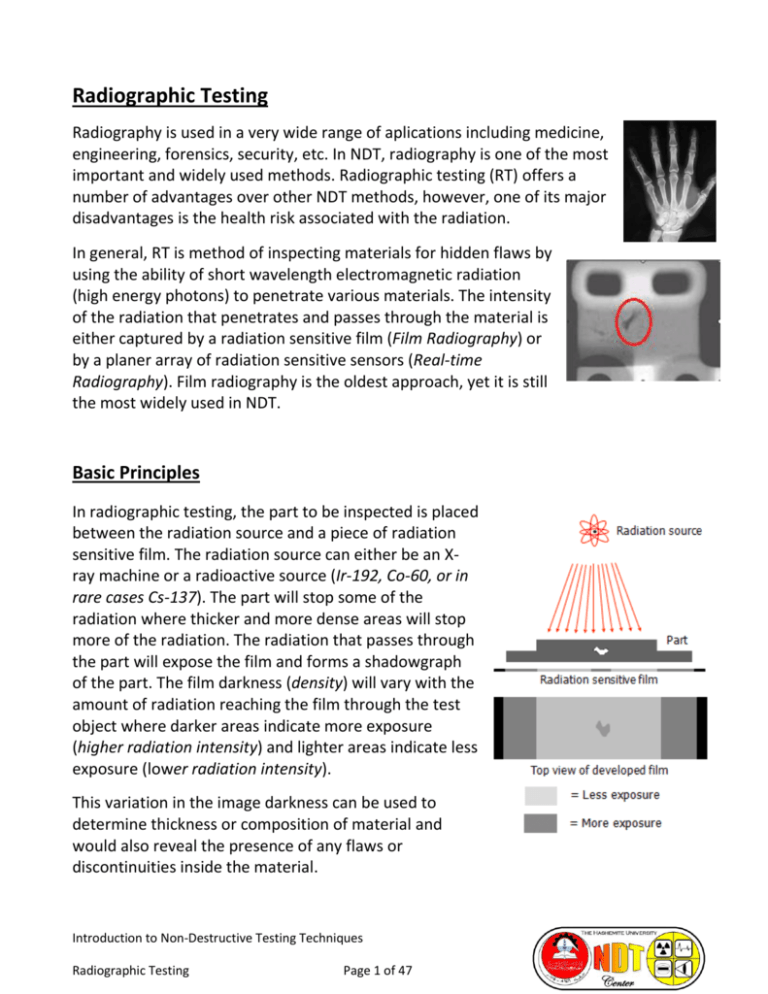

advertisement