Work and Simple Machines A. What is work? Measuring work Units

advertisement

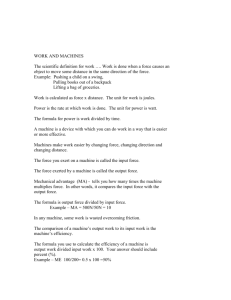

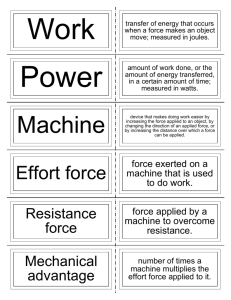

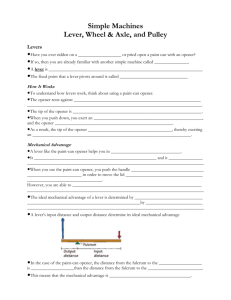

A. What is work? Work and Simple Machines • Work is done on an object when the object moves in the same direction that the force is exerted. • See examples p. 109 Chapter 4 Measuring work Work = force x distance W = Fd Force is measured in Newtons (kgm/s2) Distance is measured in meters (m) Measuring power Power = work done time to do work P=W t P=J s Power is measured in watts 1W = 1J/s Units for problems W = F x d W = N xm W = kgm/s2 x m W = kgm2/s2 This is equal to a Joule 1J = 1N x m or kgm2/s2 Work is measured in Joules B. What is a machine? • Machines make work easier by changing one of at least 3 factors: – Amount of force you exert – The distance over which you exert your force – The direction in which you exert your force 1 The Math Behind The Machine work in = work out In a perfect machine, these would be equal. Things to know: The force you put into the machine is the effort force. (or input) The force you must overcome is the resistance force. (or output) Efficiency • Compares the output work to the input work. • Expressed as a percent • In all machines some work is wasted due to friction Inclined Plane • Less effort over a longer distance • To find Mechanical Advantage: length height Mechanical advantage • Formula: actual mechanical advantage Mechanical advantage = resistance force effort force MA = Fr or output Fe input Simple machines make work easier by giving you a mechanical advantage. C. Types of Machines • Inclined plane • Wedge • Screw • Lever • Wheel and axle • Pulley For each machine we will calculate the ideal mechanical advantage Types of Inclined Planes 1. Wedge – used to increase force, split things apart or hold them together Ex: teeth, knife, doorstop, nail, pin, chisel (MA=length/width) 2. Screw – used to fasten, bore holes, lift heavy weights or move air. Ex: wall screw, drill bit, jackscrew, propellers, fans (MA=length threads/length screw) 2 Levers • Things to know: Load = what you are lifting or moving Effort =where you apply the force to move the load Fulcrum = the pivot point of a lever MA of a lever MA = distance from fulcrum to input (effort) force distance from fulcrum to output (load) force 3 lever types 1st class – fulcrum is between the effort (input) and the load (output) nd 2 class – load is between the fulcrum and the effort 3rd class – effort is between the fulcrum and the load (see examples in text p. 129) Wheel and Axle • 2 circular objects that rotate on a common axis • Larger object is the wheel, smaller one the axle • Increases force over a longer distance MA = radius of wheel radius of axle Pulleys 3 Types: 1. Fixed pulley 2. Movable pulley 3. Block and tackle 1. Fixed pulley • Only changes the direction of the force • Can be compared to turning a first class lever (fulcrum in the middle) •The mechanical advantage is 1 – you need as much effort as resistance to move an object 3 2. Movable pulley • The pulley moves along a rope or wire • Less force is used, but you need a greater distance • Can compare to a turning second class lever – the resistance is in the middle Mechanical advantage is 2 – the effort will always be half the weight of the load 3. Block and Tackle • Combination of fixed and movable pulleys • Usually no more than 4 pulleys are used (because of friction) • This type of pulley gives a change in direction and a gain in force • To find the mechanical advantage, you count the number of ropes Archimedes Screw Credits Slide 10: http://www.uark.edu/depts/aeedhp/agscience/simpmach.htg/img6.gif Slide 12: http://library.thinkquest.org/C004451F/movablepulley1.jpg slide 14: http://library.thinkquest.org/C004451F/compoundpulley1.jpg http://content.answers.com/main/content/img/McGrawHill/Encyclopedia/images/CE087300FG0010.gif Arch screw: http://etc.usf.edu/clipart/27300/27350/archimedes_27350_lg.gif 4