Amar S. Wanni and Zdenka F. Ruzek, ExxonMobil Research and

T echnological advances such as catalyst and control technologies allow operators to increase plant capacity by simply increasing flow through existing process equipment. Also, as a result of research, new design correlations enable the design of smaller and less expensive exchangers that require less space.

Higher flow rates and smaller exchangers usually result in higher velocities in the exchangers. Although a higher velocity results in a higher pressure drop, research and plant operations have shown that it often has the advantage of reducing fouling. Unfortunately, higher velocity also increases the potential for tube vibration on the shell side of the exchanger.

Damaging flow conditions have the potential to occur at the increased flow rates of a capacity expansion project, which could ultimately result in a failure in the operating unit. Replacing equipment with a larger exchanger could pose space problems and typically requires costly modifications to piping and structural members and associated downtime of the unit itself.

ExxonMobil Research and Engineering

Company (EMRE) has developed several

Amar S. Wanni and Zdenka

F. Ruzek,

ExxonMobil

Research and

Engineering

Company, USA, discuss a variety of heat exchanger/ anti-vibration technology solutions and their applications in the industry.

proprietary anti‑vibration technology (AVT) solutions that can be used to address existing or potential vibration problems.

These technologies, which are described in this article, have been applied and successfully used at many ExxonMobil and third party sites. EMRE has licensed the technologies to a select number of qualified heat exchanger manufacturers to make them available to customers worldwide.

A range of applications

There are several different application scenarios in which AVT solutions can be applied. These include both retrofit and new designs.

As a retrofit, AVT solutions can be applied either to mitigate existing vibration problems that have caused tube failure, or to prevent a problem that is predicted to occur at a debottleneck condition. For either of these cases, the AVT is a very cost effective solution.

If a tube failure has occurred, the operating conditions can be analysed to determine the necessary tube support; then the bundle can be stabilised with AVT and reinstalled in the same shell. In situations where several tubes have failed during www.hydrocarbonengineering.com Reprinted from September 2009 Hydrocarbon EnginEEring

operation, the common practice in the industry is to return the exchanger to service after plugging the failed tubes. If the failure was indeed caused by a flow induced vibration (FIV) condition, this ‘plug and run’ approach could lead to further tube failures within a matter of several weeks or even days.

This is because a whole region of the bundle is generally vulnerable to FIV. Therefore, it is always prudent to carry out a root cause failure analysis and provide vibration mitigation when necessary.

In the case of predicted vibration at a debottleneck condition, the existing bundle can be analysed to determine the extra tube support needed. Then the bundle can be removed, the AVT installed in less than a day, and the bundle reinstalled into the same shell.

In both cases, the existing shell is reused, saving significant cost to the plant.

AVT can also be applied to reduce pressure drop through the exchanger. In this case, changing from a baffled exchanger (segmental or double segmental) to a longitudinal flow configuration may be very beneficial. Depending on the stream and the impact on the heat transfer performance that results from switching to longitudinal flow on the shell side, the designer may consider a simultaneous change from bare to finned tubes. EMRE has had several successful applications in gas compression circuits.

For new exchanger design, the optimum heat transfer design point, although within the allowable pressure drop

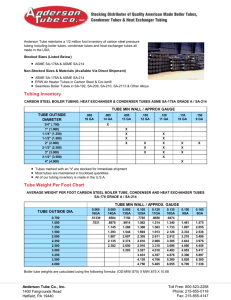

Table 1. Details of DTS application for kettle reboiler

Kettle reboiler Original exchanger

Exchanger with DTS

Duty (million Btu/h)

P (psi)

Fluidelastic instability ratio (FIR)

Vibration problems?

244

0.29

4.1

Yes

244

0.29

0.2

No

Table 2. Details of DTS application for treat gas heater

Feed/effluent heat exchanger

• TEMA BEU

• 33 in. x 126 in., 1 in. tubes

• 1180 ft 2

• Segmental baffles

Existing design conditions

49.4

30% capacity creep without

DTS

64.2

30% capacity with DTS

64.2

Duty

(million Btu/h)

∆P (psi)

Vibration problems?

8.4

No

10.0

Yes

10.2

No

Table 3. Summary of SBX application to reduce pressure drop in a compressor loop

Feed preheat with steam

Original bundle

(at debottleneck conditions)

SBX bundle

TEMA AEU

Shell: 25 in. x 126 in.

Duty (million Btu/h)

∆P (psi)

Vibration problems?

1200 ft 2

0.75 in. plain tubes segmental baffles

97.6

16

Yes

2140 ft 2

0.75 in. finned tubes no baffles (axial flow)

103

3.5

No limit, may not be acceptable because a vibration analysis may predict a potential problem. The conventional solution in such cases is to reduce the shell side velocity, which results in a less than optimal design. The lower velocity will reduce the heat transfer performance and produce a larger and more costly exchanger. However, the application of Dimpled Tube Support

(DTS™) and Saddled Tube Support (STS™) technologies can remove the vibration potential and allow the optimal design to be used.

general applications

DTS technology consists of dimpled and corrugated straight metal strips that are inserted into heat exchanger bundles to reduce vibration by stiffening the tubes. The corrugations on each strip act as a wedge to slightly deflect the tubes.

The dimples on one end of each thin strip provide a locking mechanism to hold the strip in place (Figure 1). DTS strips are inserted in alternate lanes in the regions of the bundle that have loose tubes or in which a vibration analysis predicts a high risk of damage.

DTS strips can be used in all common tube layouts and can be fabricated from many different metals. To date, they have been successfully fabricated from SS304, SS316, titanium, duplex, carbon steel, Monel, and brass.

Another application of DTS is as a U‑bend stiffener

(Figure 2), or as a vertical bundle stiffener. Whether used in a straight tube or a U‑bend application, DTS can be installed in either new or existing bundles.

Soft metal tube applications

STS technology features corrugated pairs of identical thin metal strips that are welded together and inserted into alternate tube lanes in a heat exchanger bundle in a manner similar to DTS. Figure 3 illustrates how the ‘saddle’ portion of the STS provides a wide contact area against the tubes instead of a point contact.

The tube deflection support provided by the STS is especially beneficial for use with integral fin tubes made of softer metals such as carbon steel and brass because the saddles contact multiple fins to prevent any fin damage.

STS technology is limited to 90˚ and 45˚ layouts, providing a very low profile for axial flow bundle configurations such as the Slotted Baffle Exchange (SBX™) bundle configuration, described in the following section. STS has been applied in gas compression feed preheater applications in the SBX technology.

Figure 1. DTS strips installed in a tube bundle.

Reprinted from

Hydrocarbon EnginEEring September 2009 www.hydrocarbonengineering.com

Axial flow exchangers

SBX technology consists of a relatively small number of horizontal and vertical tube support stations, along with a number of strategically placed DTS or STS strips. Given this unique configuration, SBX provides a low pressure drop and vibration free operation.

Figure 4 shows an SBX bundle that was designed for a gas compression circuit in a chemical plant. By retrofitting the existing shell with an SBX bundle having integral fin tubes, the plant was able to reduce the pressure drop from 16 to 3.5 psi while maintaining the existing feed preheat duty.

The significant savings captured from lowered operating expense (by reducing pressure drop) and capital avoidance

(by using existing shell/foundation/piping) more than offset the cost of the finned tubes.

Examples of AVT solutions

Repair of existing exchanger after tube vibration failure

A few months after the startup of a new LNG plant, several kettle reboilers suffered vibration induced tube failures because of insufficient tube support. Inspectors found that more than

10% of the tubes had significant tube fretting at the baffle hole locations and some tubes had completely holed through.

The repair decision was to plug the heavily fretted tubes and stabilise the remaining tubes through implementation of

DTS technology. The locations for and number of DTS strips were determined through a detailed vibration analysis. The analysis indicated a very high probability of fluidelastic instability at the top 12 rows of the bundle where the failures had occurred. The fluidelastic instability ratio (FIR) was calculated to be greater than four for the current conditions and was reduced to 0.2 after the DTS installation. Generally a value of less than

0.8 is recommended for new exchangers (Table 1).

The exchangers have continued in successful operation for more than four years following the restart. Overall, the plant realised significant savings by avoiding lost opportunity costs and by preventing unplanned downtime and the cost of purchasing replacement bundles.

DTS retrofit into a treat gas heater

For an expansion project on a gas cracking unit, DTS strips were retrofitted into an existing bundle in order to mitigate a vibration problem in one heat exchanger. A detailed vibration analysis showed that serious tube vibration was highly probable for a project that would increase the flow through the exchanger by 9% and heat duty by 30%.

Table 2 shows the data and installation details of this application of DTS technology. Although the pressure drop was

Figure 2. DTS strips applied as U-bend stiffener.

Figure 3. STS strip installed into a tube bundle.

www.hydrocarbonengineering.com

Figure 4. SBX bundle designed for a compressor circuit.

Table 4. Advantages of AVT solutions from EMRE

DTS

X Suitable for new U-tube bundles to reduce labour cost and fabrication time

With slight modification, acts as easier, lower cost vibration mitigation option for

U-bend region

Eliminate tube chatter and stiffen tubes

X

X

X Very unlikely to be dislodged during bundle handling, operation, or during cleaning

(common problems with other techologies)

Effective even when some of the tubes are warped

X

Suitable for vertical bundles

Strips are inserted in alternate tube lanes, minimising increase in shell side pressure drop

X

X

Provides low cost alternative for exhangers with axial flow on shell side

Minimises fabrication time through laser or water cutting of slots

Eliminates tube chatter when used with

DTS or STS to stiffen the bundle

Avoids tube vibration damage

Leads to substantial reduction in shell side pressure drop

STS

X

X

X

SBX

X

X

X

X

X

Reprinted from September 2009 Hydrocarbon EnginEEring

acceptable for the flow rate increase through the exchanger

(from 8.4 to 10.0 psi), a detailed vibration analysis predicted serious vibration problems at the inlet and outlet spans in this

TEMA BEU exchanger.

Installing a new, larger heat exchanger would have required additional space, piping modifications, and an upgraded and modified foundation resulting in significant incremental costs.

Not utilising the DTS strips, the redesigned bundle was estimated to have a shell ID of 44 in. As shown in Table 2, a detailed vibration analysis for the existing bundle after the installation of

DTS in the inlet and outlet regions predicted that the vibration potential would be eliminated. The desired 30% capacity increase was achieved with the existing exchanger with only a minimal increase in pressure drop (10.2 psi versus 10.0 psi).

This example shows that DTS technology is well suited for expansion projects because it spares significant costs of new, larger heat exchangers, piping, foundation, and other project costs associated with the purchase and the installation of a new heat exchanger. The retrofit of the DTS was conducted onsite during the turnaround. The technology is especially suited for debottlenecking condensers, reboilers, and feed/ effluent exchangers where vibration problems are often encountered during a capacity increase review.

SBX to debottleneck a gas loop with an axial flow exchanger

In the compression loop of an existing chemical plant, the pressure drop had become an increasingly significant limitation with increased throughput. Additionally, a vibration problem had developed in the existing exchangers and resulted in a tube failure.

After a vibration analysis was completed, it was decided to replace the existing baffled exchanger with an SBX axial flow bundle.

Table 3 summarises the results of this application. The replacement SBX bundle was designed with integral fin tubes to maintain the duty of the original bare tube bundle.

Significant savings in operating expense are anticipated based on the reduction in pressure drop from 16 psi to

3.5 psi. Additionally, the plant saved the capital expense of modifications to the foundation and piping that would have been required for a larger exchanger. These savings more than offset the additional cost of the finned tubes.

Summary

The three commercially proven EMRE technologies described in this article are becoming more broadly accepted in industry.

For example, these solutions have been included as options in

Heat Transfer Research, Inc.’s (HTRI) Xvib ® programme among standard FIV mitigation options when evaluating vibration potential in shell and tube heat exchangers. This feature is available starting with Xchanger ® Suite 6.

The anti‑vibration technologies offered by EMRE are available from a select number of licensed heat exchanger manufacturers worldwide. The current licencees have been trained to provide the vibration analyses, quality manufacturing and expert installation of the technologies. They can install these technologies either in their shop or at the customer’s facility with minimal space and crew requirements.

In many cases, the installation of the DTS, STS, and SBX anti‑vibration technologies has resulted in significant savings and prevented costly downtimes.

Reprinted from

Hydrocarbon EnginEEring September 2009 www.hydrocarbonengineering.com