Making the Future Through Collaborative Training

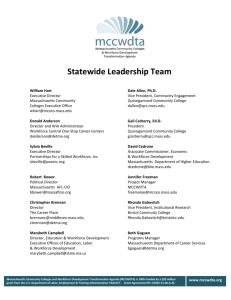

advertisement

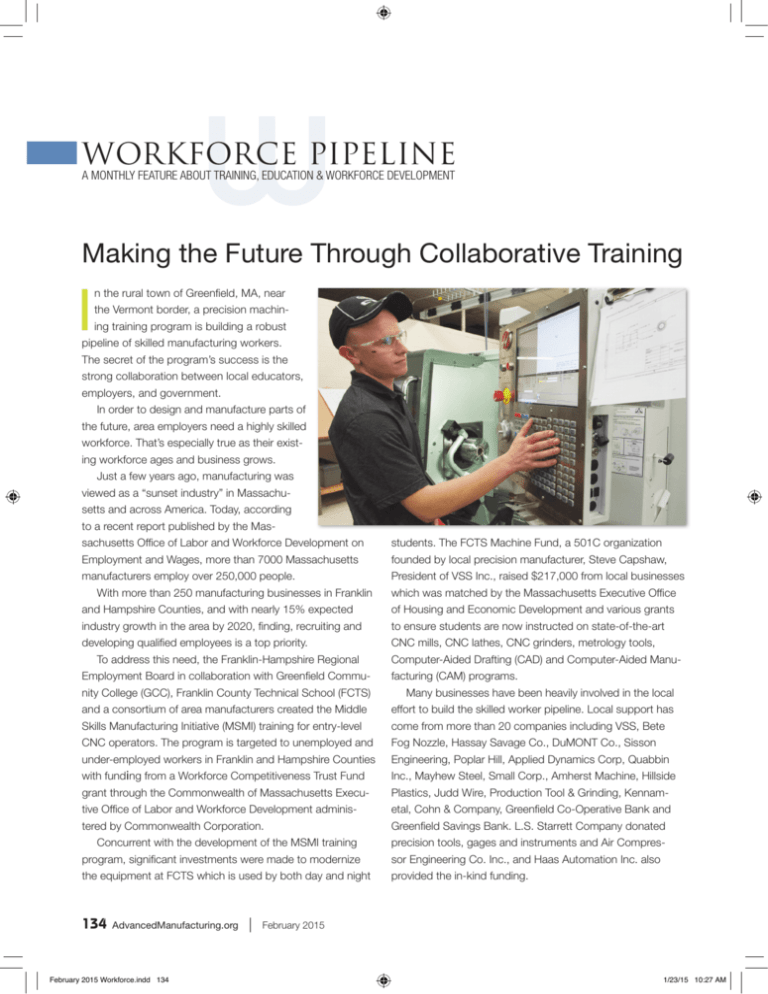

w WORKFORCE PIPELINE A MONTHLY FEATURE ABOUT TRAINING, EDUCATION & WORKFORCE DEVELOPMENT Making the Future Through Collaborative Training I n the rural town of Greenfield, MA, near the Vermont border, a precision machining training program is building a robust pipeline of skilled manufacturing workers. The secret of the program’s success is the strong collaboration between local educators, employers, and government. In order to design and manufacture parts of the future, area employers need a highly skilled workforce. That’s especially true as their existing workforce ages and business grows. Just a few years ago, manufacturing was viewed as a “sunset industry” in Massachusetts and across America. Today, according to a recent report published by the Massachusetts Office of Labor and Workforce Development on students. The FCTS Machine Fund, a 501C organization Employment and Wages, more than 7000 Massachusetts founded by local precision manufacturer, Steve Capshaw, manufacturers employ over 250,000 people. President of VSS Inc., raised $217,000 from local businesses With more than 250 manufacturing businesses in Franklin which was matched by the Massachusetts Executive Office and Hampshire Counties, and with nearly 15% expected of Housing and Economic Development and various grants industry growth in the area by 2020, finding, recruiting and to ensure students are now instructed on state-of-the-art developing qualified employees is a top priority. CNC mills, CNC lathes, CNC grinders, metrology tools, To address this need, the Franklin-Hampshire Regional Employment Board in collaboration with Greenfield Community College (GCC), Franklin County Technical School (FCTS) Computer-Aided Drafting (CAD) and Computer-Aided Manufacturing (CAM) programs. Many businesses have been heavily involved in the local and a consortium of area manufacturers created the Middle effort to build the skilled worker pipeline. Local support has Skills Manufacturing Initiative (MSMI) training for entry-level come from more than 20 companies including VSS, Bete CNC operators. The program is targeted to unemployed and Fog Nozzle, Hassay Savage Co., DuMONT Co., Sisson under-employed workers in Franklin and Hampshire Counties Engineering, Poplar Hill, Applied Dynamics Corp, Quabbin with funding from a Workforce Competitiveness Trust Fund Inc., Mayhew Steel, Small Corp., Amherst Machine, Hillside grant through the Commonwealth of Massachusetts Execu- Plastics, Judd Wire, Production Tool & Grinding, Kennam- tive Office of Labor and Workforce Development adminis- etal, Cohn & Company, Greenfield Co-Operative Bank and tered by Commonwealth Corporation. Greenfield Savings Bank. L.S. Starrett Company donated Concurrent with the development of the MSMI training precision tools, gages and instruments and Air Compres- program, significant investments were made to modernize sor Engineering Co. Inc., and Haas Automation Inc. also the equipment at FCTS which is used by both day and night provided the in-kind funding. 134 AdvancedManufacturing.org February 2015 Workforce.indd 134 | February 2015 1/23/15 10:27 AM Many of these employers also provide instructors who last summer and worked with area manufacturers such as partner with teachers from the vocational school. This is im- VSS, Hillside Plastics, Hassay-Savage and New England Natu- portant since the skills required for manufacturing jobs have rals to pilot online classes for their incumbent workers. changed dramatically as companies have incorporated new technologies into their operations. The MSMI training includes blueprint reading, math for Since the collaborative training programs began, 29 students have graduated from the MSMI program and found employment across 13 area manufacturers. Eighty-nine stu- manufacturing, metrology, CAD and CAM instruction, with a dents have enrolled in Tooling U-SME courses, completing significant portion of the current 220-hour training dedicated nearly 4000 classes. to hands-on applications in a lab/shop setting. The training is Local average overall wages in the Manufacturing sector project-based and reinforces the use of applied skills needed are $47,372, above the region’s average annual salary of in workplace situations. $37,000. The Spring cohort of 14 MSMI graduates were all placed into employment with salaries ranging from $13 to Tooling U-SME Supports Program Students also have additional online assignments to demonstrate their mastery of the topics learned in class. Green- $19 per hour to start and averaging $15.50 with opportunities for continued advancement and training. Advanced manufacturing is booming in Massachusetts and field Community College partnered with Tooling U-SME, the collaborative manufacturing training programs underway a division of SME, a leader in manufacturing training and will continue to be expanded to provide a range of options that development. Subscriptions to the Tooling U-SME courses meet the needs of students. Greenfield Community College were funded by the Massachusetts Community College and is one of the 15 Massachusetts Community Colleges funded The Middle Skills Manufacturing Initiative (MSMI) trains entry-level CNC operators and was created through a collaboration between educators, employers and government. Workforce Development Transformations Agenda (MC- by TAACCCT grants to address the training and educational CWDTA), which is fully funded through a $20 million Trade needs of workers and employers statewide with a focus on Adjustment Assistance Community College and Career articulated pathways to careers in high-growth STEM sec- Training (TAACCCT) grant from the US Department of Labor tors (Science, Technology, Engineering, and Math) as well as Employment and Training Administration. advanced manufacturing and healthcare. Instructors and area businesses collaborated on the Improving the perception of manufacturing is critical to en- specific Tooling U-SME classes to supplement the hands-on courage students and potential workers to choose manufac- training. Once the required courses were completed, stu- turing education and careers. The MassDevelopment Office’s dents were encouraged to continue to take online classes to “AMP It Up!” campaign showcases how advanced manufac- build their skills and work with their employers to customize a turing careers can put Massachusetts and its workers on the training program upon hire. path to success through creative, highly skilled, and well- The MSMI program, launched in Fall 2013, has quickly paying jobs. As our local billboard profiling two of our MSMI received very positive feedback. More than 100 people ap- graduates states, advanced manufacturing provides “Great plied for the 15 training slots in that initial class and Tooling careers and strong futures.” U-SME online subscriptions were provided to 12 “runnerup” applicants to build their skills until the next training. This approach successfully allowed students to showcase their Alyce Stiles is the Director of Workforce Development at Greenfield Community in Greenfield, MA. motivation, willingness to learn new skills and be on the top of the recruitment list for the next training. To further help develop skilled workers, Greenfield Community College developed a Foundational Manufacturing Training February 2015 February 2015 Workforce.indd 135 | AdvancedManufacturing.org 135 1/23/15 10:27 AM